Preparation method and application of thia-graphene/gamma-Fe2O3 nano composite material

A technology of nanocomposite materials and graphene, applied in chemical instruments and methods, analyzing materials through chemical reactions, and analyzing materials through observation of the impact on chemical indicators, can solve problems such as identification and achieve simple processes , easy to operate, large specific surface area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0031] The graphene oxide used in embodiment 2, embodiment 3 is prepared by the following method:

[0032] GO was prepared by the improved Hummers method: 1 g of natural flake graphite was added to 50 mL of concentrated H 2 S 2 o 4 (98%), cool to zero; slowly add 0.5g KNO 3 and 6g KMnO 4 . React for 4 hours under the condition that the reaction temperature is controlled not to exceed 10°C. Then the system was transferred to a constant temperature water bath at 35° C. for stirring for 2 h, 300 mL of deionized water was added, and the reaction was continued for 2 h at ≤80° C. With an excess of 5% H 2 o 2 Reduction of remaining KMnO 4 , and washed several times with 5% HCl, and finally fully washed with enough deionized water until the solution no longer contained SO 4 2- Ions (BaCl 2 No white precipitate was detected). The final product was transferred to a 65°C oven for drying and stored for future use.

Embodiment 1

[0034] Weigh 80mg Fe 2 (SO 4 ) 3 Put it into a sealed quartz tube filled with Ar, put the sealed quartz tube into a tubular heating furnace, raise the temperature to 650 °C at a rate of 10 °C / min, and keep it for 2 hours, cool it down to room temperature naturally, take out the calcined product, and finally obtain nanomaterials α-Fe 2 o 3 .

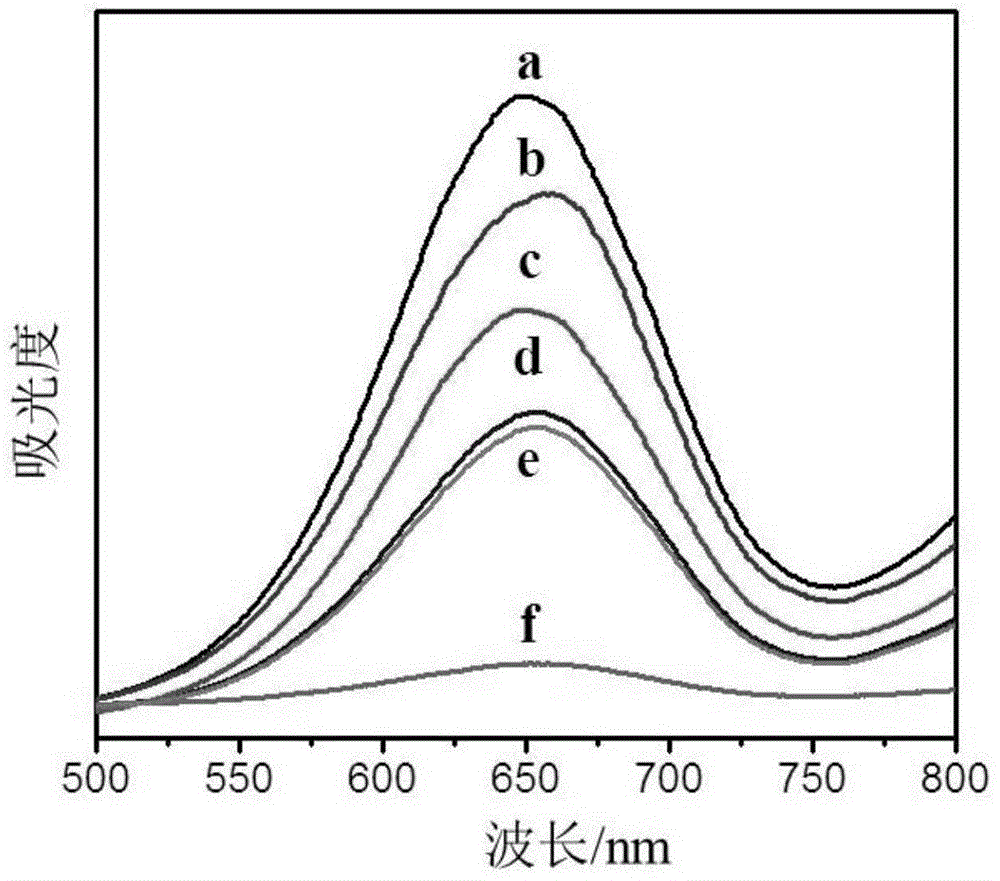

[0035] The sample prepared in this example is used for microfluidic technology to detect lactic acid by colorimetry, and the steps are as follows:

[0036] (1) Prepare solution and dispersion, prepare 100 μL alcohol solution containing 0.5 mg TMB; configure 100 μL phosphate buffer solution (PBS, 10 mM, pH 7.4) containing 0.5 unit lactate oxidase; configure 5×10 –4 、10 –3 , 0.05, 0.01, 0.1, 1, 10 μmol lactic acid in phosphate buffer solution (PBS, 10mM, pH 7.4) each 100μL; configure 200μL 0.2M acetate buffer solution (ABS, pH 4.0); configure 2mg / mL α-Fe 2 o 3 water dispersion;

[0037] (2) 200 μL of the α-Fe was passed through the...

Embodiment 3

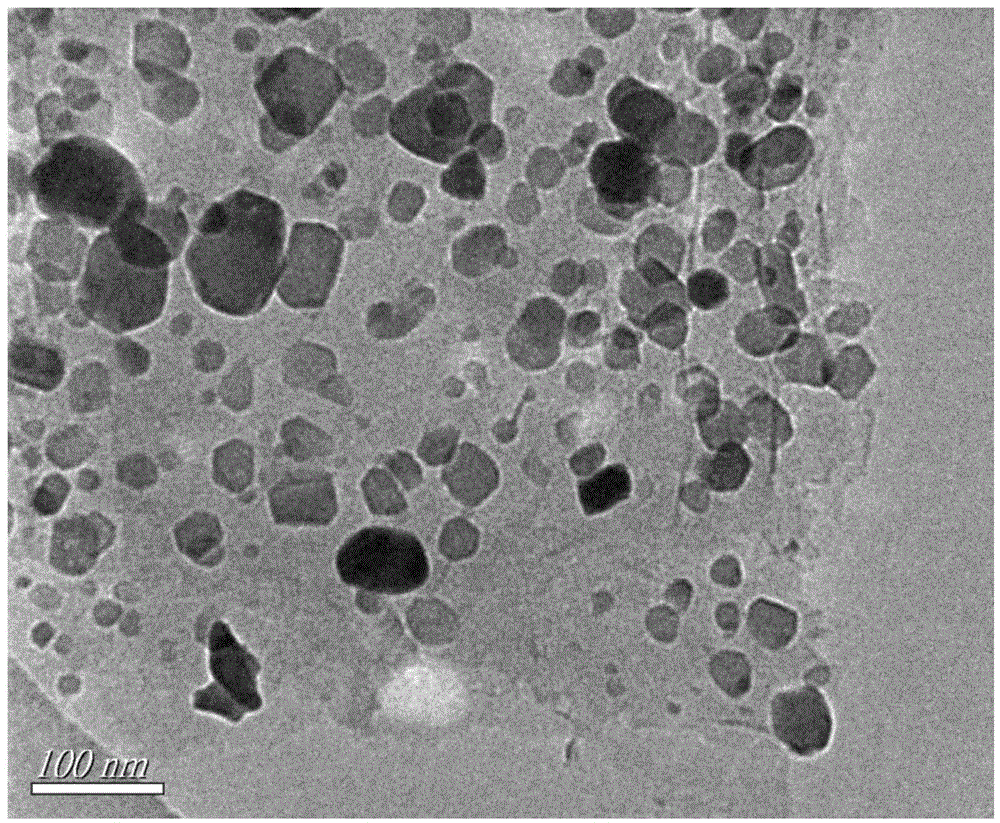

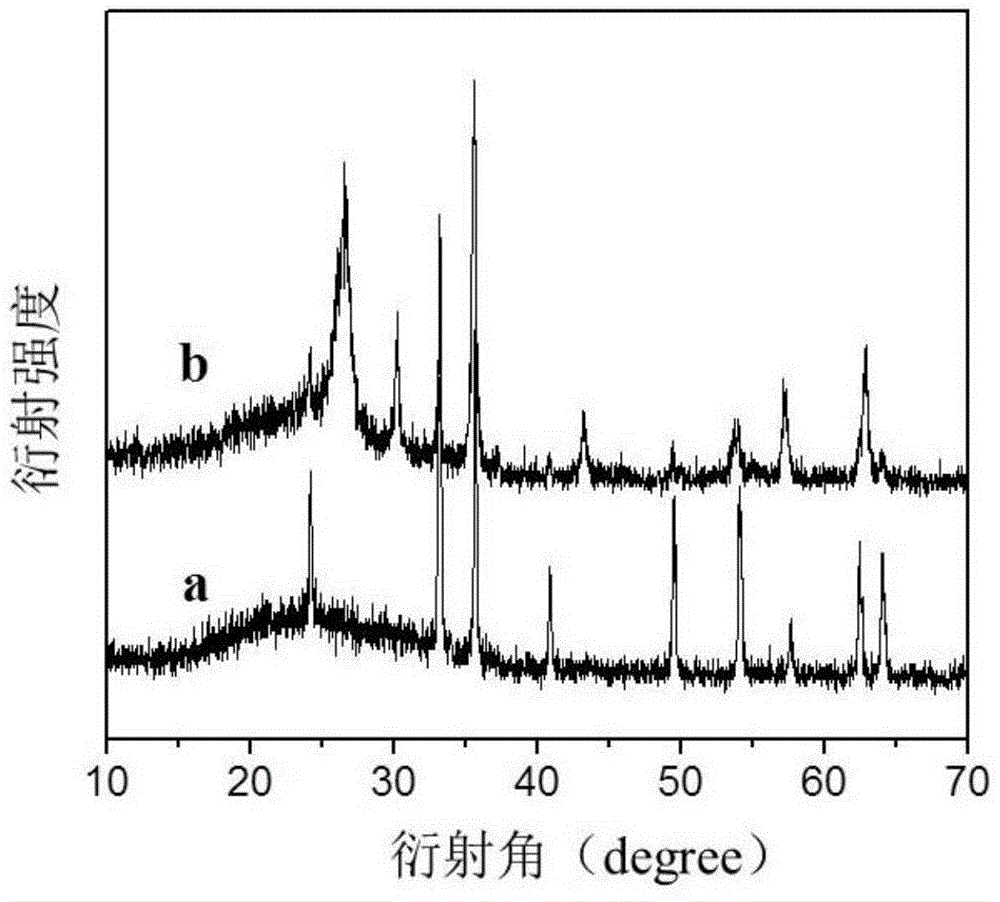

[0048] Weigh 10 mg of solid graphene oxide and dissolve it in 20 mL of water to prepare a 0.5 mg / mL graphene oxide aqueous solution. Weigh 4mg Fe 2 (SO 4 ) 3 Join in above-mentioned graphene oxide solution, obtain graphene oxide / Fe 2 (SO 4 ) 3 mixture. Graphene oxide / Fe 2 (SO 4 ) 3 The mixed solution was continuously ultrasonicated for 30 minutes and then transferred to 60°C for 12 hours to obtain graphene oxide / Fe 2 (SO 4 ) 3 solid mixture. The above graphene oxide / Fe 2 (SO 4 ) 3 The solid mixture is filled with N 2 Put the stainless steel sealed tube into a tube-type heating furnace, raise the temperature to 480 °C at 3 °C / min, and keep it for 2 hours, cool to room temperature naturally, take out the calcined product, and finally get the nanocomposite S / G / γ-Fe 2 o 3 .

[0049] The sample prepared in this example was used in microfluidic technology to detect lactic acid by colorimetry, and the steps were the same as in Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com