MABR-MBR combined type sewage treatment device and treatment method

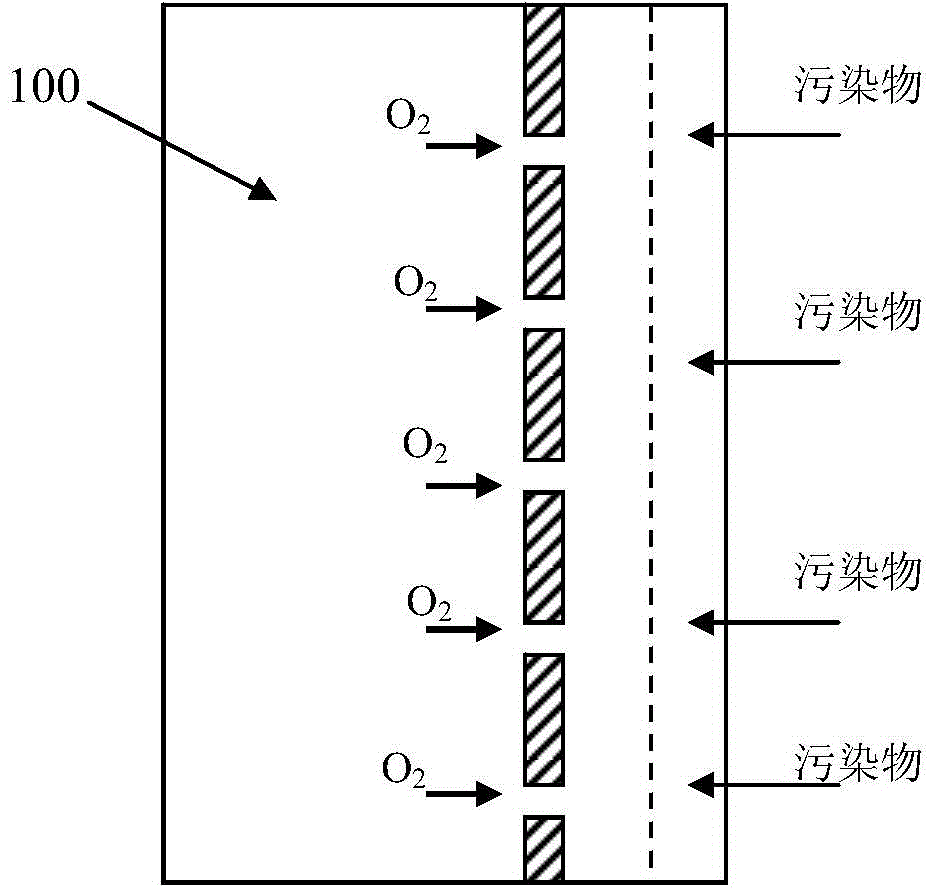

The technology of a sewage treatment device and treatment method, which is applied in the field of MABR and MBR combined sewage treatment equipment, can solve the problems of high energy consumption, low oxygen utilization rate, and high maintenance cost of the aeration system, so as to save infrastructure costs and reduce volume The effect of low load and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

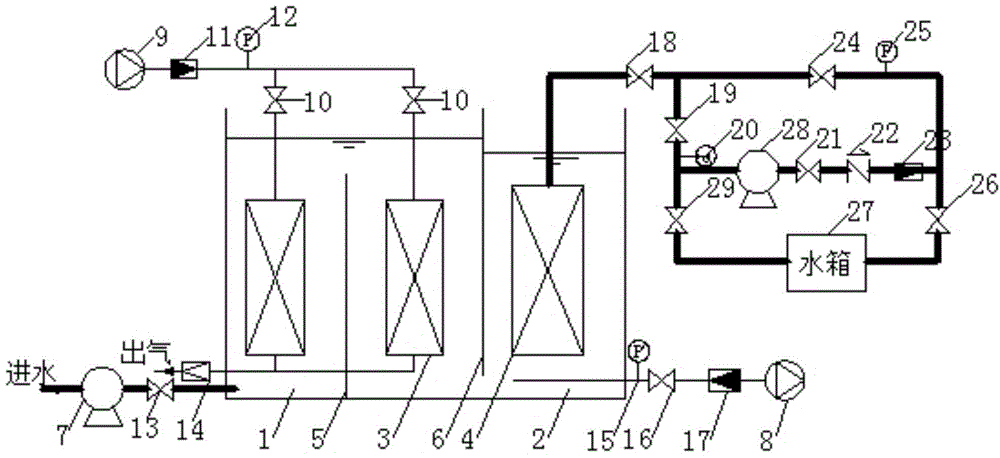

[0040] use as figure 2 The MABR-MBR integrated wastewater treatment device with the structure shown is fed into the pretreated domestic sewage. The domestic sewage is the shower wastewater from a bathing center. The water quality indicators are: COD: 140mg / L, NH3-N: 42mg / L, SS: 45mg / L, LAS: 6.2mg / L, MABR membrane module material is polyvinylidene fluoride (PVDF), inner diameter 0.4mm, outer diameter 0.45mm, MBR membrane module material is the same as MABR membrane, pore size is 0.1 um, the membrane flux is 16L / (m 2 h). Firstly, the pretreated water is pumped into the MABR tank by the water inlet pump, and at the same time, aeration is made to the MABR membrane cavity. The water treated by the membrane enters the MBR tank through the diversion wall, and is aerated at the bottom of the tank. The sludge concentration is 4500-5500mg / L, and a sludge discharge pipe is installed at the bottom of the MBR reactor to discharge the remaining sludge regularly. The water quality afte...

Embodiment 2

[0042] The processing device is the same as in Example 1. The influent water adopts pretreated landscape lake water with severe eutrophication, and its water quality indicators are COD: 83mg / L, TP: 0.23mg / L, TN: 13mg / L, NH 3- N: 0.8 mg / L. The operating conditions are basically the same as in Example 1: in the MABR tank, the aeration pressure is about 0.07-0.1MPa, the pH is controlled at 7.5-8.5, and the hydraulic retention time is controlled at 8h; in the MBR tank, the aeration rate is adjusted so that the dissolved oxygen concentration is controlled at 3.5~4.5mg / L, PH at 7.5~8, hydraulic retention time at 6h, sludge concentration at 4000~5000mg / L. At room temperature, after the device runs stably, the effluent indicators are COD: <11mg / L, TP: <0.08mg / L, TN: <2.3mg / L, NH3-N: <0.2mg / L.

Embodiment 3

[0044] The processing device is the same as in Example 1. The influent is pretreated cornstarch wastewater, and its water quality index is COD: 8350mg / L, NH 3- N: 13mg / L, TN: 210mg / L, SS: 2200mg / L, PO 4- : 48mg / L, PH: 3.4. The operating conditions are basically the same as those in Example 1 except for the following: in the MABR pool, the aeration pressure is about 0.07-0.1MPa, the pH is controlled at 7.5-8.5 by adding NaOH, and the hydraulic retention time is controlled at 12h; in the MBR pool, the dissolved oxygen The concentration is controlled at 3.5-4mg / L, the pH is 7.5-8, the hydraulic retention time is controlled at 9h, and the sludge concentration is 6000-9000mg / L. After the device runs stably, its effluent indicators are COD: 4- : <2mg / L, PH: 7.1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com