Preparation method of hydrophobic lipophilic sponge aerogel composite material

A hydrophobic, lipophilic and composite material technology, applied in the field of porous materials, can solve the problems of long preparation cycle, low compressive strength, gel structure damage, etc., and achieve easy portability and transportation, enhanced mechanical strength, and less organic solvent. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The specific operation steps for preparing hydrophobic and lipophilic sponge airgel composites are as follows:

[0031] 1. Mix 10ml of methyltrimethoxysilane with 20ml of ethanol, and add 50ml of deionized water (the molar ratio of the three is 1:2.45:15.84) for stirring to form a silicon source solution.

[0032] 2. Add 0.1mol / L hydrochloric acid to the silicon source solution to adjust the pH value of the solution to about 3.6, then add 0.1g F127, stir at room temperature for 20 minutes, add concentrated ammonia water with a concentration of 10mol / L and stir to obtain a pH value of about 8 silica sol.

[0033] 3. Pour the silica sol into a container containing a polyurethane sponge block (3cm×3cm×3cm), and let it stand for 2 hours to form a wet gel.

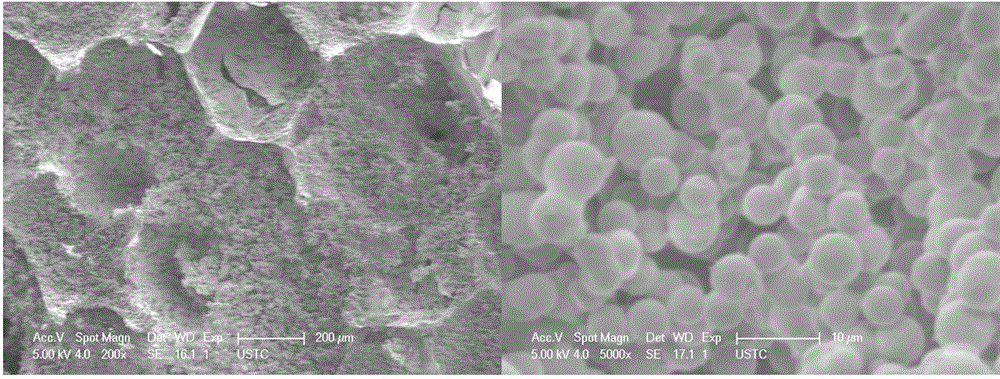

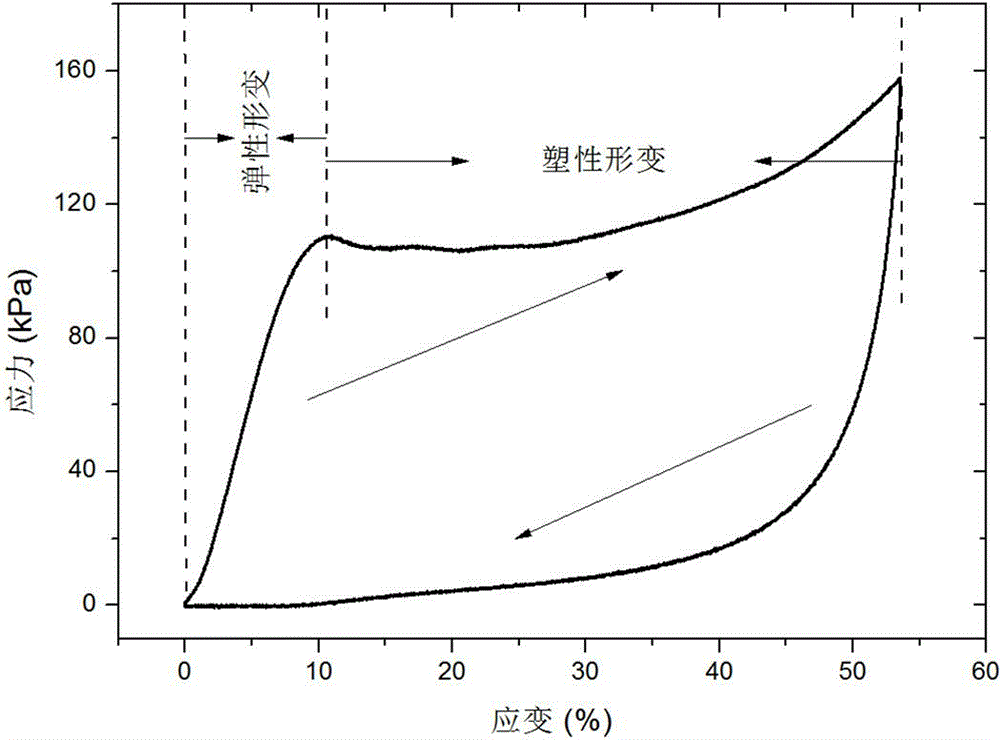

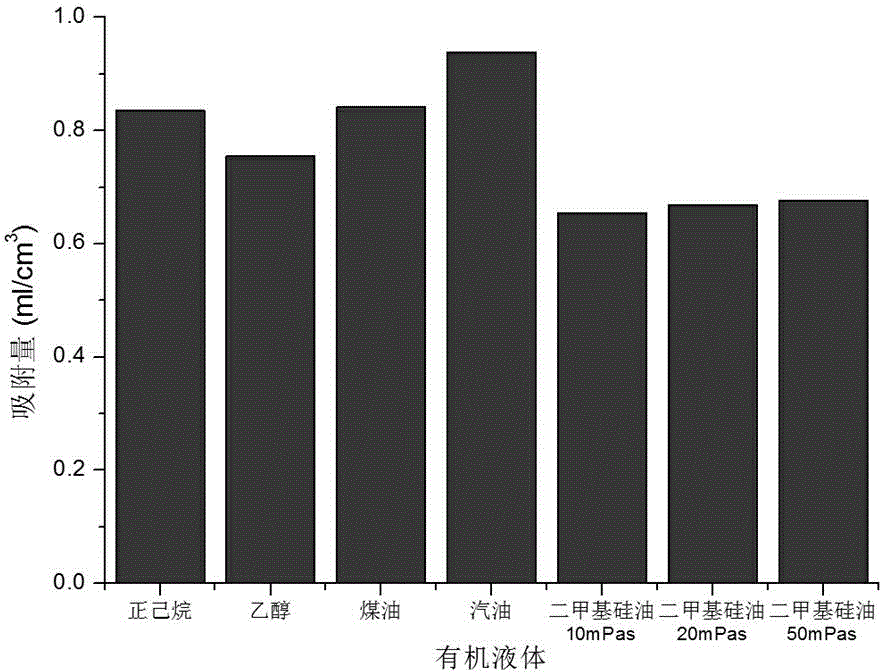

[0034] 4. Put the wet gel in a drying oven at 100°C and dry it under normal pressure for 6 hours to obtain a hydrophobic and adsorbable sponge-silica airgel composite material with a density of 0.114 g / cm3, a porosity o...

Embodiment 2

[0036] The specific operation steps for preparing hydrophobic and lipophilic sponge airgel composites are as follows:

[0037] 1. Mix 10ml of methyltriethoxysilane with 12.7ml of methanol and add 18.1ml of deionized water (the molar ratio of the three is 1:4.9:15.84) for stirring to form a silicon source solution;

[0038] 2. Add ammonium fluoride with a concentration of 0.5mol / L to the silicon source solution to adjust the pH value of the solution to about 3.8; after stirring at room temperature for 20 minutes, add concentrated ammonia water with a concentration of 5mol / L and stir to obtain silicon with a pH value of about 8. Sol;

[0039] 3. Pour the silica sol into a container containing a polyurethane sponge block (3cm×3cm×3cm), and let it stand for 2 hours to form a wet gel;

[0040]4. Put the wet gel in a drying oven at 80°C and dry it under normal pressure for 8 hours to obtain a hydrophobic and adsorbable sponge-silica airgel composite material with a density of 0.102...

Embodiment 3

[0042] The specific operation steps for preparing hydrophobic and lipophilic sponge airgel composites are as follows:

[0043] 1. Mix 10ml of ethyltriethoxysilane with 17.4ml of isopropanol and add 13.2ml of deionized water (the molar ratio of the three is 1:4.9:15.84) for stirring to form a silicon source solution;

[0044] 2. Add 0.1mol / L hydrochloric acid to the silicon source solution to adjust the pH value of the solution to about 4; then add 0.1g F127, stir at room temperature for 20 minutes, then add concentrated ammonia water with a concentration of 10mol / L and stir to obtain a pH value of about 8 silica sol;

[0045] 3. Pour the silica sol into a container containing a polyurethane sponge block (3cm×3cm×3cm), and let it stand for 6 hours to form a wet gel;

[0046] 4. Put the wet gel in a drying oven at 100°C and dry it under normal pressure for 6 hours to obtain a hydrophobic and adsorbable sponge-silica airgel composite material with a density of 0.121g / cm3, a poro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com