Pure alpha-phase molybdenum carbide-loaded noble metal catalyst, and preparation method and application thereof

A noble metal catalyst, molybdenum carbide technology, applied in physical/chemical process catalysts, chemical instruments and methods, catalytic treatment of combustible gases, etc., can solve the problem of reducing the specific surface area of molybdenum carbide and the exposure of surface catalytic active sites, long preparation cycle, The operation process is cumbersome and other problems, and the effect of excellent water vapor shift performance and excellent catalytic performance is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

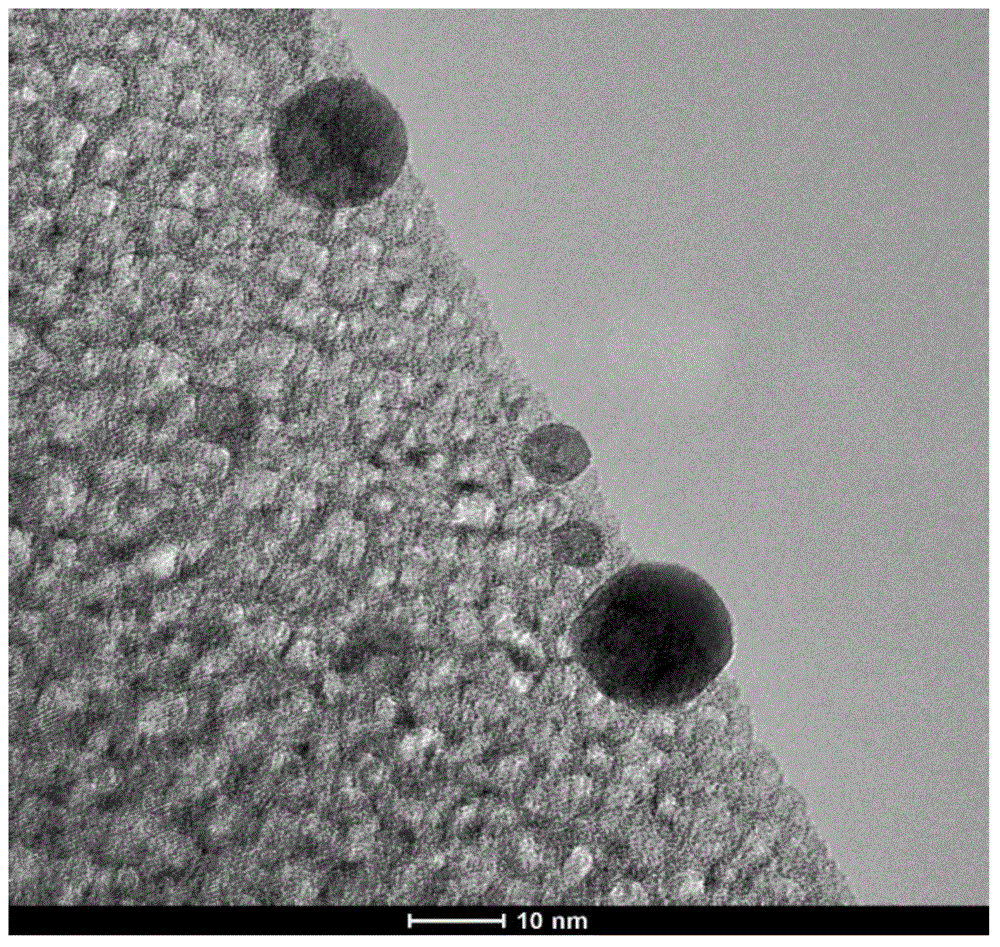

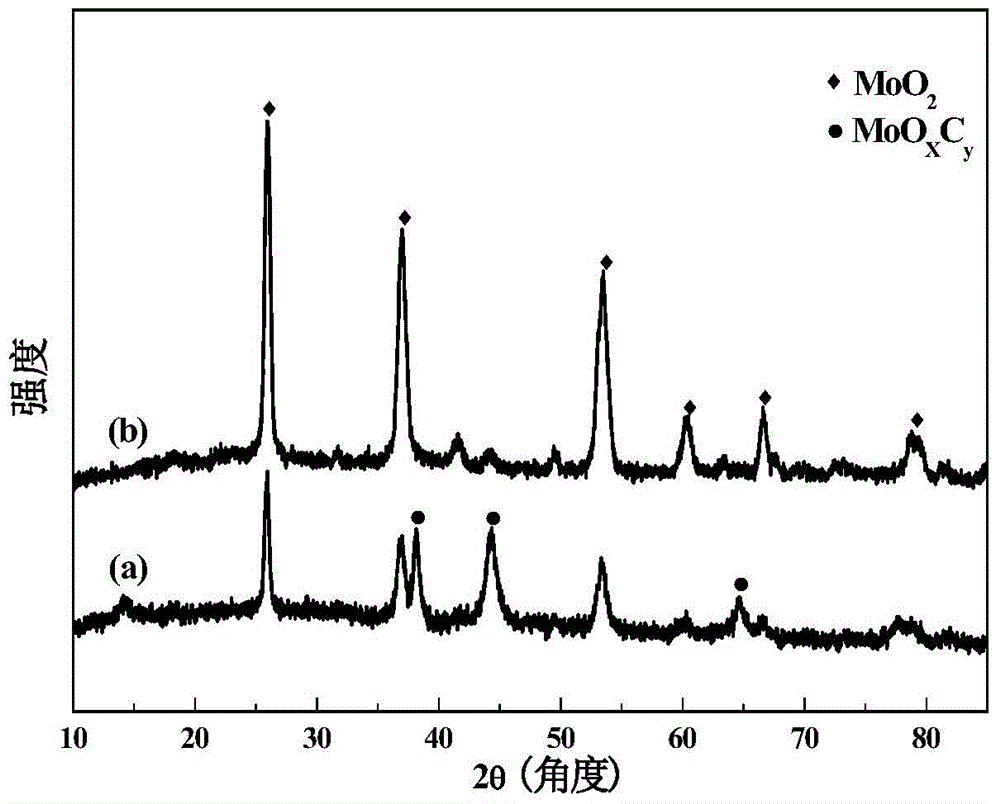

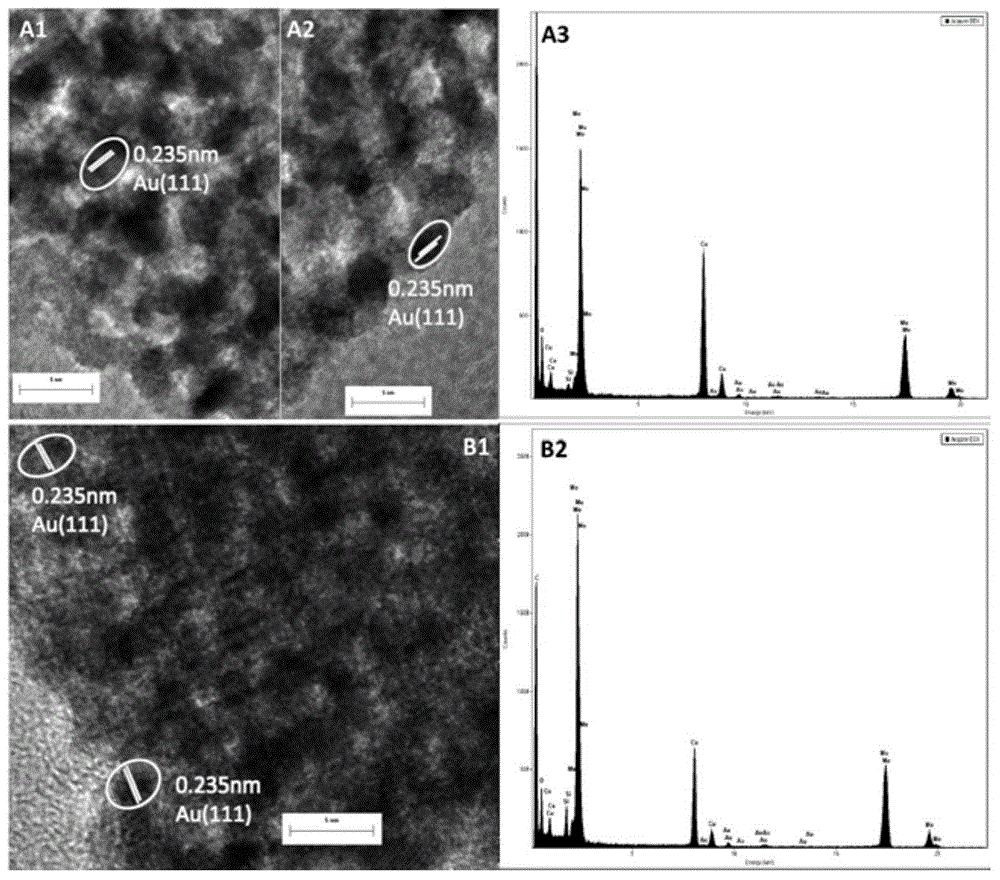

[0042] (1) Dissolve 6.92g of ammonium paramolybdate in 40ml of deionized water, stir magnetically at room temperature to dissolve completely; then add 5.93ml of chloroauric acid solution with a concentration of 0.02428mmol / ml into the ammonium paramolybdate solution dropwise , stirred at room temperature in the dark for 4-5 hours, filtered to obtain a white precipitate, washed with water, evaporated to dryness in a water bath at 80°C, and dried overnight at 110°C to obtain a precursor with a loading mass percentage of 0.5% Au;

[0043] (2) Place the precursor with a loading mass percentage of 0.5% Au in a dielectric barrier discharge (DBD) non-equilibrium plasma reactor, use oxygen (100ml / min) as the working gas, and use non-equilibrium plasma for treatment. Two electrodes Apply an AC voltage of 6000v on the top, and the treatment time is 30min to obtain molybdenum oxide with a loading mass percentage of 0.5% Au (recorded as 0.5%Au / MoO 3 -plasma);

[0044] (3) Take 1.2g 0.5% ...

Embodiment 2

[0047] The steps and processing conditions of the present embodiment are all the same as in Example 1, the difference is only in the following two points, 1. take 36.5ml of chloroauric acid solution and prepare the pure α-phase molybdenum carbide catalyst with a loading mass percentage of 3% Au (note 3% Au / α-MoC 1-x ); ②Evaluate its activity, the reaction atmosphere is: by volume fraction, 11%CO / 26%H 2 O / 26%H 2 / 7%CO 2 / 30%N 2 , the gas mass space velocity is 90000ml / g / h, and the reaction temperature is 120-400°C. At 150 °C, the conversion of CO was 82%.

Embodiment 3

[0049] The steps and processing conditions of the present embodiment are all the same as in Example 1, and the difference is only in the following two points. 1. take 62.2ml of chloroauric acid solution to prepare the pure α-phase molybdenum carbide catalyst of loading mass percentage 5% Au (note 5% Au / α-MoC 1-x ); ②Evaluate its activity, the reaction atmosphere is: by volume fraction, 11%CO / 26%H 2 O / 26%H 2 / 7%CO 2 / 30%N 2 , the gas mass space velocity is 90000ml / g / h, and the reaction temperature is 120-400°C. At 150 °C, the conversion of CO was 86%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com