Method for improving water-removing performance of urban sludge by coupling treatment of ultrasonic wave and chitosan

A technology of municipal sludge and dewatering performance, applied in the direction of dewatering/drying/concentrating sludge treatment, etc., can solve the problems of low removal rate, secondary pollution, leakage, etc., to improve dewatering performance, reduce usage, and reduce costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

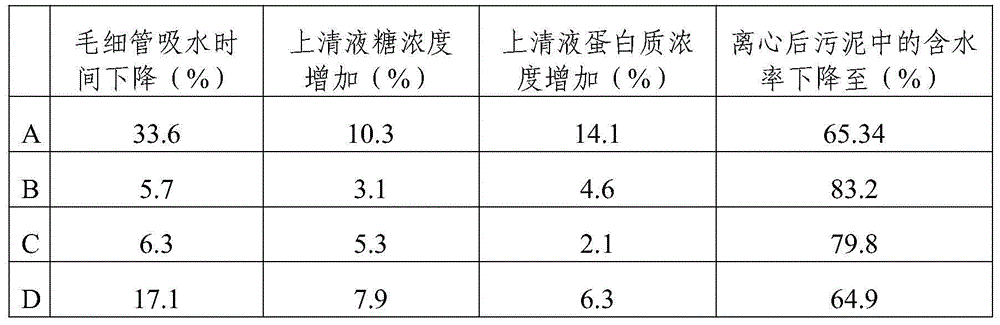

Examples

Embodiment 1

[0025] A method for improving municipal sludge dewatering performance through ultrasonic-chitosan coupling treatment, comprising the following steps:

[0026] (1) The sludge is placed in the adjustment tank, and the pH value of the sludge is adjusted to 4 by adding acid solution therein, then 600 mg of chitosan is added to it according to every liter of sludge, and then the magnetic stirrer is first used at 290r / Min stirred for 0.9min, then adjusted the stirring speed to 47r / min and stirred for 10min;

[0027] (2) Ultrasonic treatment is used to treat the sludge to be used in step 1. The ultrasonic treatment is to immerse the ultrasonic probe in the place 80mm below the sludge liquid surface, and adjust the ultrasonic frequency to 20kHz, and the sound energy density is controlled at 0.3W / mL. Ultrasonic treatment for 1 min, and then put it in a centrifugal dehydrator for centrifugal dehydration treatment, the improvement of sludge dewatering performance can be completed.

[0...

Embodiment 2

[0031] A method for improving municipal sludge dewatering performance through ultrasonic-chitosan coupling treatment, comprising the following steps:

[0032] (1) The sludge is placed in the regulating tank, and the pH value of the sludge is adjusted to 6.5 by adding acid solution therein, then adding 800 mg of chitosan per liter of sludge, and then using a magnetic stirrer at 310r / m Min stirred for 1.2min, then adjusted the stirring speed to 53r / min and stirred for 15min;

[0033] (2) The sludge to be treated in step 1) is treated with ultrasonic treatment. The ultrasonic treatment is to immerse the ultrasonic probe in the place 120mm below the sludge liquid surface, and adjust the ultrasonic frequency to 200kHz, and the sound energy density is controlled at 0.6W / mL. Ultrasonic treatment for 5 minutes, and then put it in a centrifugal dehydrator for centrifugal dehydration treatment, the improvement of sludge dewatering performance can be completed.

[0034] Described acid l...

Embodiment 3

[0037] A method for improving municipal sludge dewatering performance through ultrasonic-chitosan coupling treatment, comprising the following steps:

[0038] (1) The sludge is placed in the regulating tank, and the pH value of the sludge is adjusted to 5.5 by adding acid solution therein, then adding 700 mg of chitosan according to each liter of sludge, and then using a magnetic stirrer at 300r / Min stirring treatment for 1min, then adjust the stirring speed to 50r / min stirring treatment for 13min;

[0039](2) Ultrasonic treatment is used to treat the sludge to be used in step 1. The ultrasonic treatment is to immerse the ultrasonic probe in the place 100mm below the sludge liquid surface, and adjust the ultrasonic frequency to 100kHz, and the sound energy density is controlled at 0.5W / mL. Ultrasonic treatment for 3 minutes, and then put it in a centrifugal dehydrator for centrifugal dehydration treatment, the improvement of sludge dewatering performance can be completed.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com