A kind of flame retardant based on naphthylaminocyclotriphosphazene and preparation method thereof

A technology of naphthylaminocyclotriphosphazene and cyclotriphosphazene, which is applied in the field of flame retardants based on naphthylaminocyclotriphosphazene and its preparation, and can solve the problems of low thermal stability and affecting the performance of flame retardants , to achieve the effects of good thermal stability, excellent flame retardant effect and high thermal decomposition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

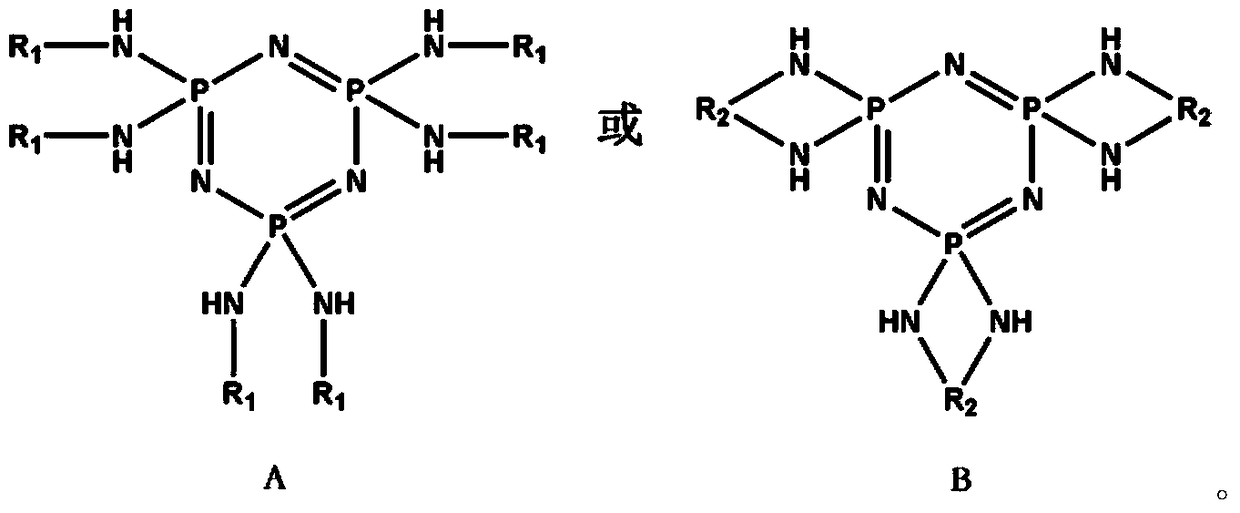

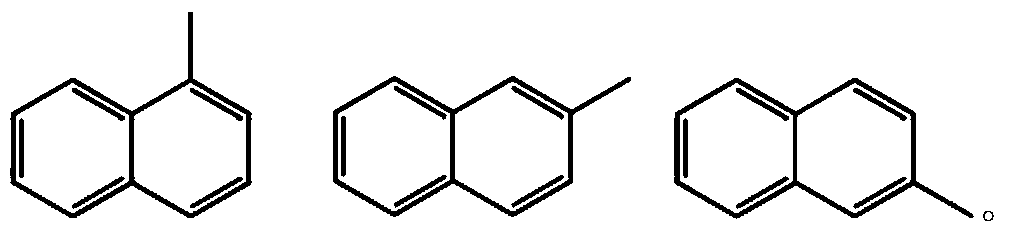

[0028] In a 250ml three-necked round-bottomed flask equipped with a spherical condenser, mechanical stirring, and constant pressure dropping funnel, add 6.95g (0.02mol) of hexachlorocyclotriphosphazene and 10.28g (0.065mol) of 1,8-naphthalene diamine , toluene 100ml, stirring to dissolve the solid particles completely.

[0029] Weighed 12.12g (0.12mol) of triethylamine, slowly added dropwise to the above-prepared solution at room temperature, raised the temperature to 110°C and refluxed for 12h.

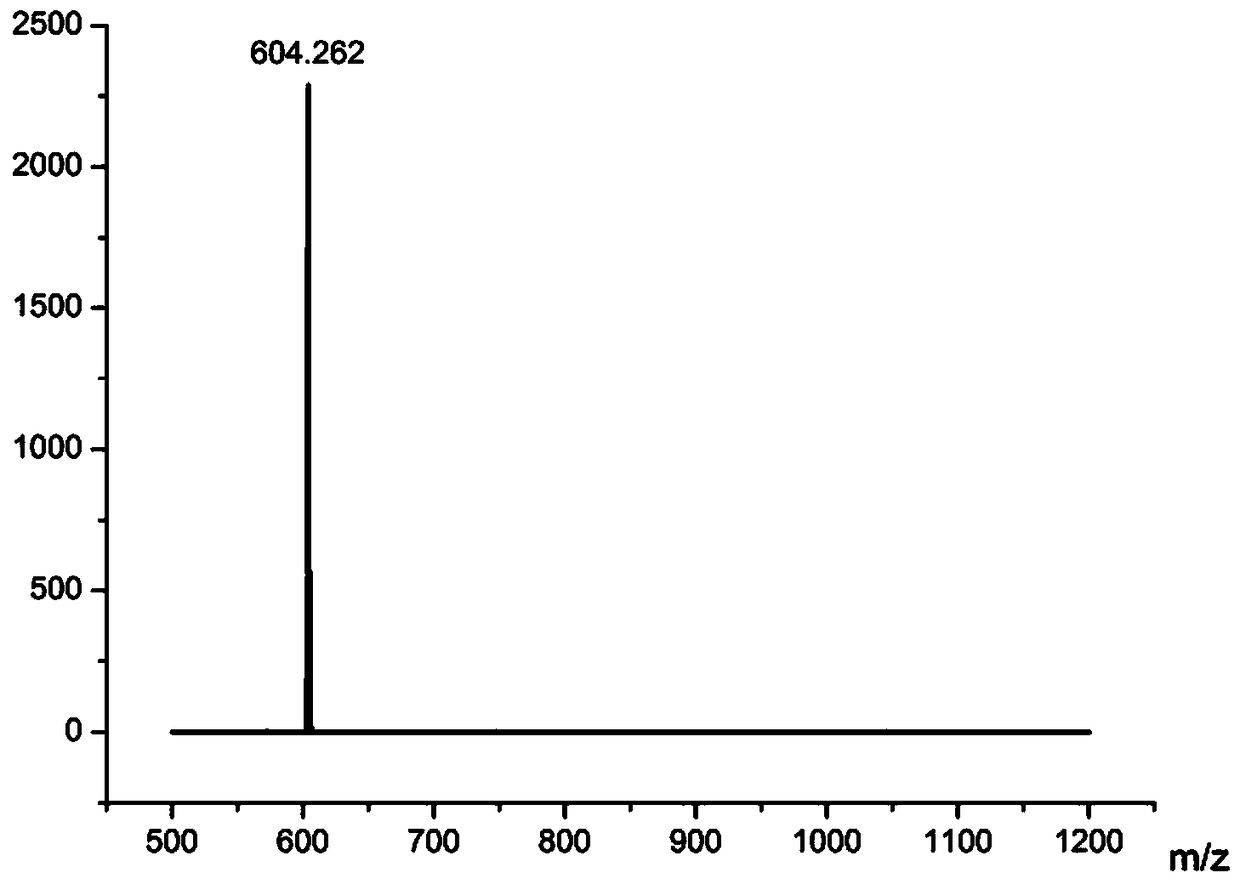

[0030] After cooling to room temperature, the reaction solution was suction-filtered, the toluene in the filtrate was recovered, and the filter cake was washed 3 times with deionized water, and then washed with tetrahydrofuran to remove the remaining raw materials in the solid, and vacuum-dried at 50°C for 10 h to obtain a light gray solid. That is the product tris-1,8-naphthalenediaminocyclotriphosphazene with a yield of 90.2%.

Embodiment 2

[0032] In a 250ml three-necked round-bottomed flask equipped with a spherical condenser, mechanical stirring, and constant pressure dropping funnel, add 12.28g (0.02mol) of hexabromocyclotriphosphazene and 10.28g (0.065mol) of 1,8-naphthalene diamine , add toluene 100ml, stir to dissolve the solid particles completely.

[0033] Weighed 12.12g (0.12mol) of triethylamine, slowly added dropwise to the above-prepared solution at room temperature, raised the temperature to 110°C and refluxed for 12h.

[0034] After cooling to room temperature, the reaction solution was suction-filtered, the toluene in the filtrate was recovered, and the filter cake was washed 3 times with deionized water, and then washed with tetrahydrofuran to remove the remaining raw materials in the solid, and vacuum-dried at 50°C for 10 h to obtain a light gray solid. That is the product tris-1,8-naphthalenediaminocyclotriphosphazene with a yield of 93.2%.

Embodiment 3

[0036] In a 250ml three-neck round-bottomed flask equipped with a spherical condenser, mechanical stirring, and constant pressure dropping funnel, add 6.95g (0.02mol) of hexachlorocyclotriphosphazene and 18.62g (0.13mol) of 1-naphthylamine, and add toluene 100ml, stir to dissolve the solid particles completely.

[0037] Weighed 12.12g (0.12mol) of triethylamine, slowly added dropwise to the above-prepared solution at room temperature, raised the temperature to 110°C and refluxed for 12h.

[0038] After cooling to room temperature, suction filter the reaction solution, recover the toluene in the filtrate, wash the filter cake 3 times with deionized water, and then wash with tetrahydrofuran to remove the remaining raw materials in the solid, and vacuum-dry at 50°C for 10 hours to obtain a solid powder, which is The product hexanaphthylaminocyclotriphosphazene has a yield of 91.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com