Ferulic acid producing engineering strain, construction method and biotransformation method

A production engineering and construction method technology, applied in the field of biotransformation, catalyzing eugenol to produce ferulic acid engineering strains, can solve the problems of high energy consumption, high price, a large amount of acid-base waste, etc., and achieve simple implementation methods and high industrial efficiency the effect of value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

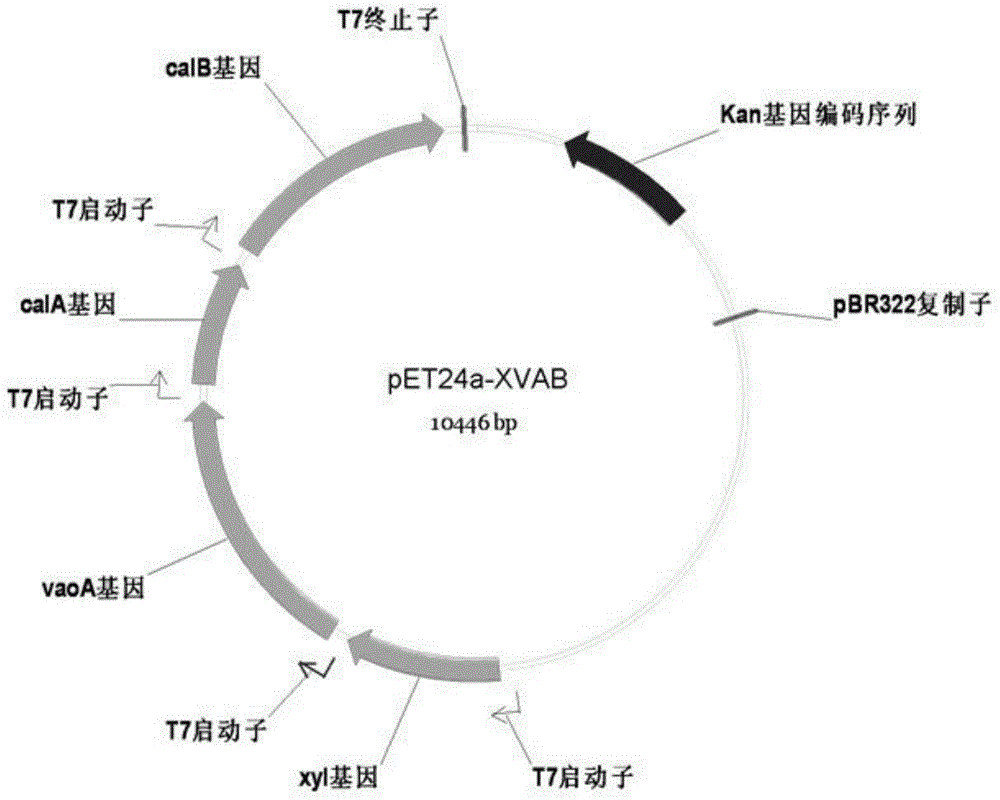

[0039] A method for constructing ferulic acid production engineering strains, comprising the following steps:

[0040] 1. Construction of strains containing recombinant plasmid pET24a-vaoA

[0041] 1) Plasmid construction

[0042] Plasmid pET24a(+): a product of Novagen, with a size of 5.31kb, containing a kanamycin resistance gene, a lactose repressor lac I gene, a T7 promoter, and multiple restriction endonuclease sites.

[0043] The DNA fragment of the vanillyl oxidase gene (vaoA, 1683bp) was digested with Nde I and Bam HI. The vector pET24a(+) was double digested with Nde I and Bam HI. Enzyme digestion system: DNA 43 μL, buffer R 5 μL, Bam HI 1 μL, Nde I 1 μL, incubated at 37°C for 3 hours.

[0044] The digested DNA fragments were gel-recovered, and the vaoA and carrier DNA fragments were ligated with T4 ligase. The ligation system was as follows: 7.5 μL of vaoA, 1.5 μL of pET24a vector, 1 μL of buffer, and 1 μL of T4 ligase. Transformed into Escherichia coli host stra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com