Inorganic ion modified zeolite composite material and application thereof

A composite material and modified zeolite technology, applied in other chemical processes, adsorbed water/sewage treatment, energy and wastewater treatment, etc., can solve the problems of long aging time of hydrotalcite-like, no research on removal rate, and no removal efficiency. , to achieve the effect of improving the longer aging time and shortening the aging time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1 Preparation of Inorganic Ion Modified Zeolite Composite Material

[0028] (1) Add MgCl to deionized water 2 , AlCl 3 and FeCl 3 , prepared as A solution, wherein, MgCl 2 The concentration is 0.75mol / l, AlCl 3 The concentration is 0.225mol / l, FeCl 3 The concentration is 0.025mol / l;

[0029] (2) Add NaOH and Na to deionized water 2 CO 3 Prepare B solution, wherein, NaOH concentration is 2mol / l, Na 2 CO 3 The concentration is 0.5mol / l;

[0030] (3) Take artificial zeolite, grind it to a powder with a particle size of 60-80 mesh, and prepare a zeolite suspension with a concentration of 50g / l (in the specific operation process, natural zeolite can also be used);

[0031] (4) Load the inorganic ionic hydrotalcite on the surface of zeolite by PH co-precipitation method, the specific method is as follows: take 200mL each of A solution, B solution and zeolite solution, stir the zeolite suspension at a rate of 120rpm, and then drop into it at the same time Sol...

Embodiment 2

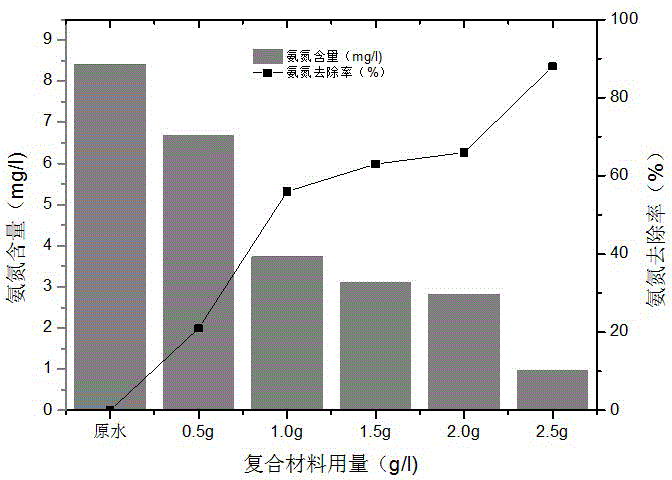

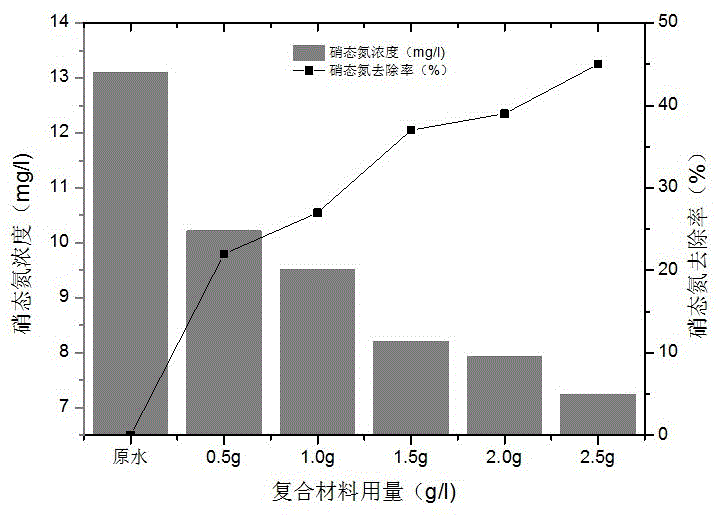

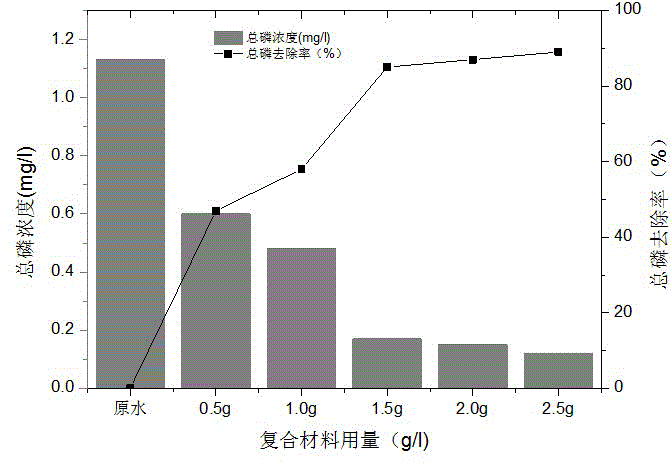

[0034] Example 2 Simulated urban sewage secondary effluent treatment effect test

[0035] Simulated sewage preparation: adopt the configuration of simulating the biochemical secondary effluent of urban sewage, specifically, the concentration of ammonia nitrogen, nitrate nitrogen, and total phosphorus are 8mg / l, 12mg / l, and 1mg / l respectively;

[0036] experiment procedure:

[0037] (1) Experimental group: 0.1g, 0.2g, 0.3g, 0.4g, 0.5g of the inorganic ion-modified zeolite composite material obtained in Example 1 were weighed and added to a conical flask containing 200ml of simulated sewage. paper seal;

[0038] (2) Control group: Weigh 0.1g, 0.2g, 0.3g, 0.4g, 0.5g of 60-80mesh artificial zeolite, add them into a conical flask containing 200ml of simulated sewage, and seal it with tinfoil;

[0039] Each group of Erlenmeyer flasks was kept at a constant temperature of 25°C and 100rpm for 6 hours, and the concentrations of ammonia nitrogen, nitrate nitrogen, and total ph...

Embodiment 3

[0041] Example 3 Test of treatment effect of biochemical secondary effluent of sewage treatment plant

[0042] (1) Source of sewage: In 2015, a 1L water sample was taken from the secondary sedimentation tank of Matougang Urban Wastewater Treatment Plant in Zhengzhou City, and the concentrations of ammonia nitrogen, nitrate nitrogen and total phosphorus in the effluent of the secondary sedimentation tank were respectively determined to be 3.48mg / l, 1.81mg / l, 0.51mg / l;

[0043] (2) Weigh 0.1g, 0.2g, 0.3g, 0.4g, and 0.5g of the inorganic ion-modified zeolite composite material obtained in Example 1, respectively, and add them to a conical flask containing 200ml of sewage, and seal it with tinfoil;

[0044] Shake at a constant temperature at 25°C for 6 hours, measure the concentrations of ammonia nitrogen, nitrate nitrogen, and total phosphorus before and after the reaction, and calculate the removal effects of ammonia nitrogen, nitrate nitrogen, and total phosphorus. With...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com