Nanometer material increase manufacturing method of upstream pumping mechanical seal

A technology of additive manufacturing and mechanical sealing, which is applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve the problems of low manufacturing precision, rough sandblasting surface, distortion, etc., to improve the sealing effect, easy to process the substrate, and avoid The effect of bad influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

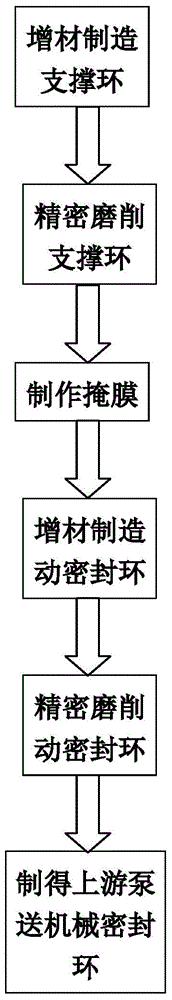

[0022] Such as figure 1 As shown, the nano-additive manufacturing method of the upstream pumping mechanical seal, the steps are as follows:

[0023] 1. Additive manufacturing support ring, the specific steps are as follows:

[0024] (1), preparation of plating solution:

[0025] The components of the plating solution are 1000mL of distilled water, 55-60g of boric acid, 380-400g of nickel sulfate, 17-20g of nickel chloride, 0.1-0.2g of sodium lauryl sulfate, 6-8g of activated carbon, and 4-6mL of hydrogen peroxide. During the preparation process, first pour boric acid and 990mL distilled water into the beaker successively, heat in a water bath at 70-90°C and stir with a glass rod to dissolve the boric acid; then pour in nickel sulfate and nickel chloride, continue heating in a water bath and stir with a glass rod until completely Dissolve; pour activated carbon particles and hydrogen peroxide reagent to activate for 30 minutes, and filter with filter paper for use; pour sodiu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com