A kind of polyimide fiber and preparation method thereof

A technology of polyimide fiber and imidization, applied in the field of fiber or fiber fabric, can solve the problems such as severe temperature difference alternation in space, shape limitation, shedding, etc., to achieve the effect of improving elongation at break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] The present invention also provides a kind of preparation method of above-mentioned polyimide fiber, comprising:

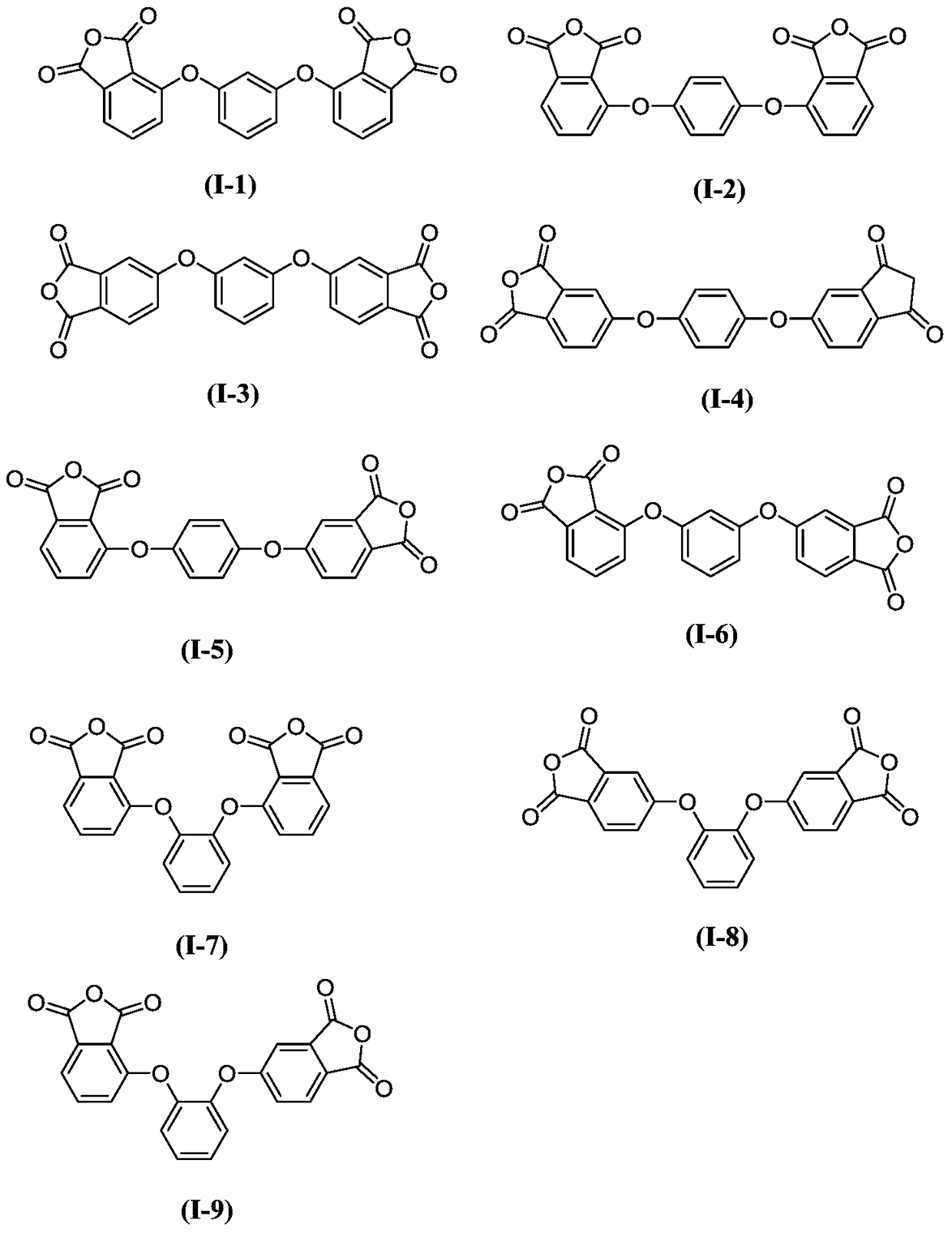

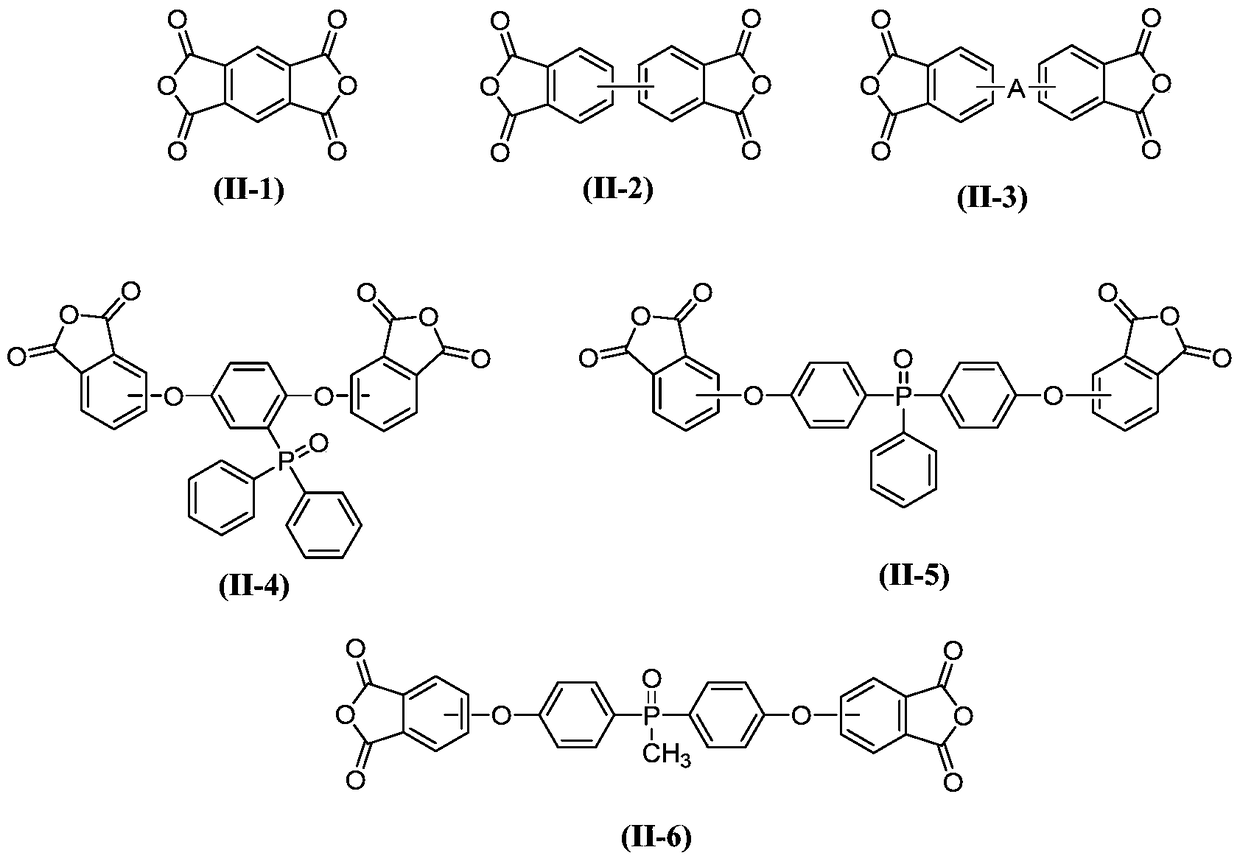

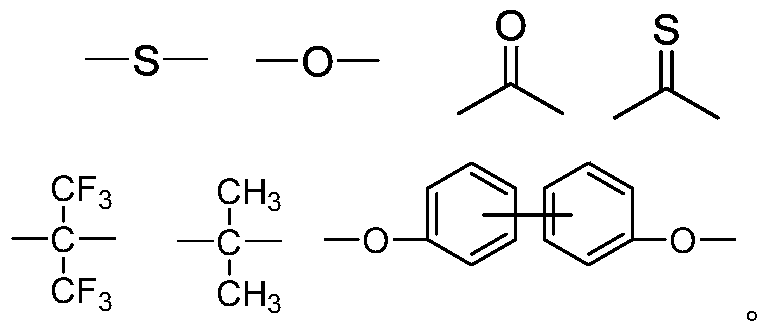

[0055] A) Polymerize the dianhydride compound and the diamine compound to obtain a polyamic acid spinning solution; the dianhydride compound and / or the diamine compound contains phosphorus; the dianhydride compound includes at least the following formula (I-1)~ One or more of the structures of formula (I-9):

[0056]

[0057] B) spinning the polyamic acid spinning solution to obtain polyamic acid fibers;

[0058] C) Imidizing the polyamic acid fibers to obtain polyimide fibers.

[0059] The present invention has no special limitation on the sources of all raw materials, which can be commercially available or self-made. The types of the diamine compound and the dianhydride compound are the same as those described above, and will not be repeated here.

[0060] The dianhydride compound and the diamine compound are polymerized, and the molar ratio of the ...

Embodiment 1

[0081] 1.1 Dissolve 192.23g (0.96mol) of 4,4'-diaminodiphenyl ether, 59.10g (0.24mol) of bis(3-aminophenyl)methylphosphine (III-11) in 4025ml of dimethyl sulfoxide , add 176.53g (0.60mol) biphenyltetralic acid dianhydride and 241.38g (0.60mol) 1,3-bis(3,4-dicarboxyphenoxy)phthalic anhydride (I-3) under stirring state, React at 50° C. for 4 hours to obtain a light yellow viscous polyamic acid spinning solution (concentration: 15 wt %), which is directly used as spinning slurry after filtering.

[0082] 1.2 The polyamic acid slurry obtained in 1.1 is spun and formed by dry-wet spinning technology. After the spinning slurry at room temperature is accurately measured by a metering pump, it is extruded from the spinneret hole and enters the dimethyl In the coagulation bath of sulfoxide and water (1:4 volume ratio). The spinneret has 200 holes, the hole diameter is Φ0.15mm, the spray ratio is 1.6 times, the spinning speed is 30m / min, and the air layer height is 10mm. The as-spun f...

Embodiment 2

[0087] The molar ratio of the diamine monomer in Example 1 was adjusted so that the phosphorus-containing monomer accounted for 40%. With other conditions unchanged, polyimide fibers were obtained.

[0088] The polyimide fiber obtained in Example 2 was analyzed, and the tensile breaking strength of the fiber was 4.41 cN / dtex, the initial modulus was 49.31 cN / dtex, and the elongation at break was 98%.

[0089] The AO irradiation test was carried out on the polyimide fiber obtained in Example 2, and the strength retention data of the fiber after irradiation is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com