Isolating membrane for lithium ion secondary battery

A secondary battery and separator technology, applied in secondary batteries, battery components, circuits, etc., can solve the problems of complex process, difficult process control, complex process, etc., to improve thermal stability, suppress deformation, The effect of inhibiting shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

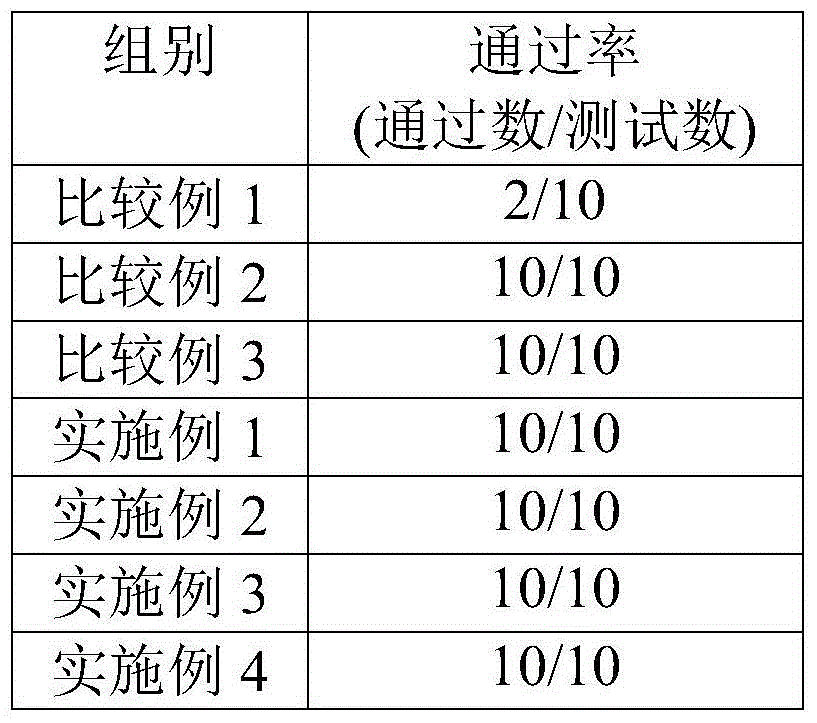

Examples

Embodiment 1

[0044] The preparation of the positive electrode sheet, the negative electrode sheet and the battery of this embodiment are the same as those of Comparative Example 1, and will not be repeated. The separator is different from Comparative Example 1. The separator and its preparation are described in detail below:

[0045] A polyethylene microporous film with a thickness of 9 μm was used as the main body of the isolation membrane.

[0046] Preparation of functional coating slurry:

[0047] 1) Add Al to deionized water first 2 o 3The particles were stirred for 1h, the solid content was 40wt%, and then ground in a ball mill for 1h, then added to the acrylate emulsion (the content of polyacrylate in the aqueous solution was 25wt%) and stirred for 1h, the mass ratio of Al2O3 to acrylate was 80:20, Then add polyvinylidene fluoride-hexafluoropropylene powder and stir for 2h, Al 2 o 3 The mass ratio of polyvinylidene fluoride-hexafluoropropylene is 50:50, the solid content of the s...

Embodiment 2

[0050] The preparation of the positive electrode sheet, the negative electrode sheet and the battery of this embodiment are the same as those of Comparative Example 1, and will not be repeated. The separator is different from Comparative Example 1. The separator and its preparation are described in detail below:

[0051] A polyimide with a thickness of 9 μm is used as the isolation membrane body.

[0052] Preparation of functional coating slurry:

[0053] 1) First add boehmite particles into deionized water and stir for 1 hour, the solid content is 30wt%, then grind in a ball mill for 1 hour, then add polyacrylonitrile emulsion (the content of polyacrylonitrile in the aqueous solution is 20wt%) and stir for 1 hour, The mass ratio of boehmite to polyacrylonitrile is 90:10, then polyoxyethylene powder is added and stirred for 2 hours, the mass ratio of boehmite to polyoxyethylene is 80:20, and the solid content of the slurry is 33wt% , the average particle size of boehmite part...

Embodiment 3

[0056] The preparation of the positive electrode sheet, the negative electrode sheet and the battery of this embodiment are the same as those of Comparative Example 1, and will not be repeated. The separator is different from Comparative Example 1. The separator and its preparation are described in detail below:

[0057] A polypropylene microporous film with a thickness of 9 μm was used as the isolation membrane body.

[0058] Preparation of functional coating slurry:

[0059] 1) Add TiO to the mixed solvent of ethanol and deionized water (the mass of ethanol and deionized water is 50:50) 2 The particles were stirred for 1 h, the solid content was 30 wt%, and then ground in a ball mill for 1 h, then added sodium carboxymethyl cellulose solution (concentration of sodium carboxymethyl cellulose solution was 1.5 wt%) and stirred for 1 h, TiO 2 The mass ratio with sodium carboxymethyl cellulose is 95:5, then add polymethacrylate (PMMA) powder and stir for 2h, TiO 2 The mass rati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Particle size distribution range | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com