Nanometer silicon and carbon composite negative electrode material and preparation method and lithium ion battery thereof

A technology of negative electrode material and negative electrode active material, which can be used in batteries, battery electrodes, secondary batteries, etc., and can solve the problems of cycle stability, rate performance and unsatisfactory safety performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

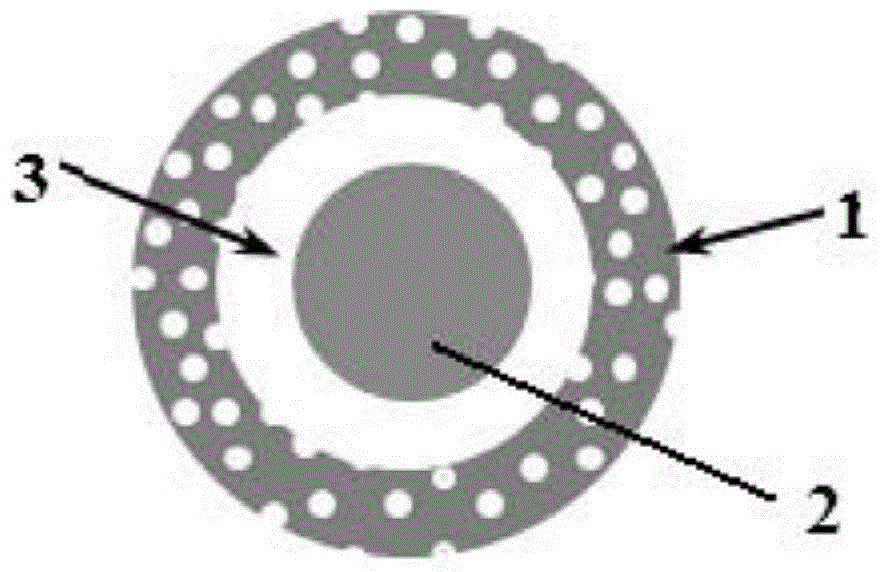

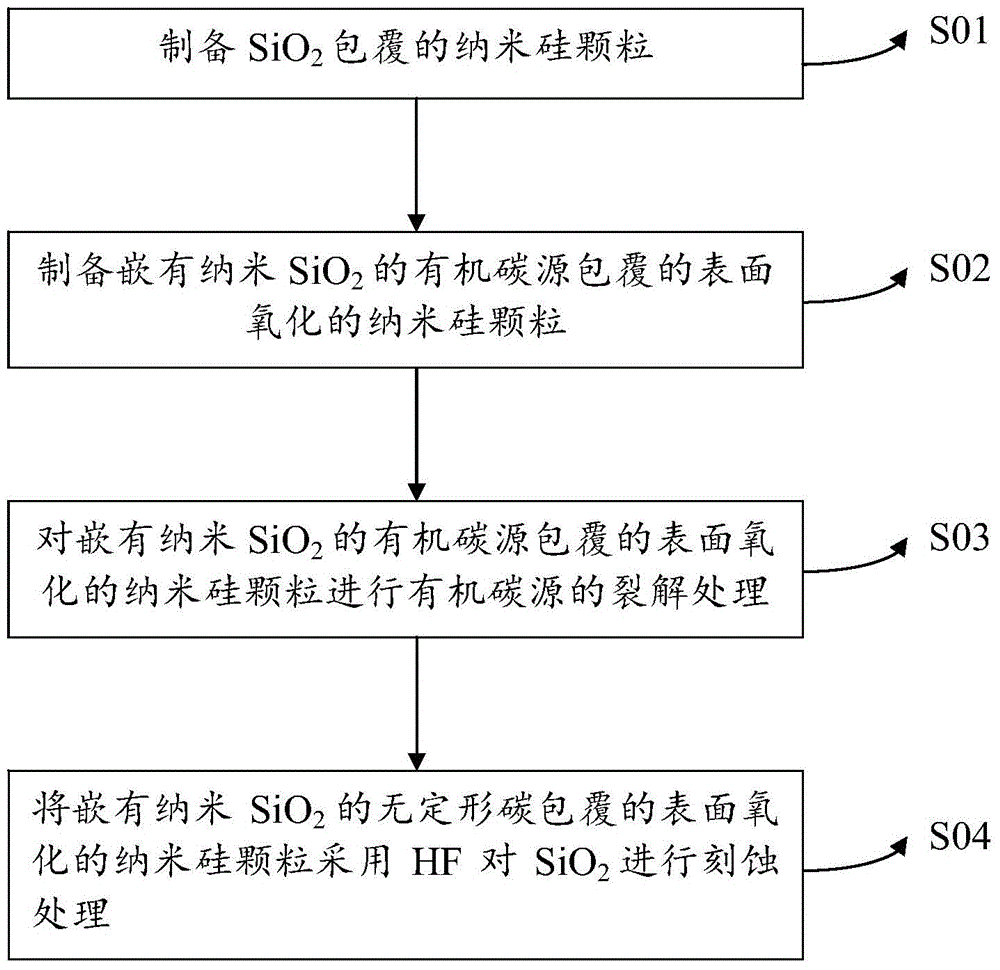

[0034] Correspondingly, the embodiment of the present invention also provides a preparation method of the above-mentioned nano-silicon-carbon composite negative electrode material. The process flow of the nano-silicon-carbon composite negative electrode material preparation method is as follows: figure 2 As shown, it includes the following steps:

[0035] Step S01. Preparation of SiO 2 Coated nano-silicon particles: place the nano-silicon particles in an oxygen-containing atmosphere and calcine and oxidize them at 700-1000°C to obtain SiO 2 Coated nano-silicon particles;

[0036] Step S02. Preparation of embedded nano-SiO 2 Surface Oxide Nano-Si Particles Coated with Organic Carbon Source: Nano-SiO 2 particles, the SiO 2The coated nano-silicon particles, dispersant and organic carbon are dispersed in a solvent, and then spray-dried to obtain nano-SiO 2 Surface oxidized nano-silicon particles coated with an organic carbon source, the surface oxidized nano-silicon particl...

Embodiment 1

[0058] A silicon-carbon composite material and a preparation method thereof. The silicon-carbon composite material preparation method comprises the following specific steps:

[0059] S11: Calcining and oxidizing 3g of nano-silicon powder with a diameter of about 100nm in air at a temperature of 900°C for 3 hours, and cooling to obtain SiO 2 Nano-silica powder coated on the outer layer.

[0060] S12: In this embodiment, the outer-layer-coated nano-silicon powder obtained in step S11 and 1 g of sodium dodecylsulfonate are mixed in an appropriate amount of deionized water, and fully stirred to obtain a stable suspension solution 1. 0.5 g of nano-SiO with a diameter of 15 nm 2 The powder and 22.5g of phenolic resin were evenly dispersed in the ethanol solution to form solution 2. After mixing solution 1 and solution 2 with magnetic stirring and dispersing for 60 minutes, the uniformly dispersed suspension was spray-dried at a high temperature at an inlet temperature of 220° C. ...

Embodiment 2

[0065] A silicon-carbon composite material and a preparation method thereof. The silicon-carbon composite material preparation method comprises the following specific steps:

[0066]S21: Calcining and oxidizing 2g of nano-silicon powder with a diameter of about 100nm in air at a temperature of 900°C for 1 hour, and cooling to obtain SiO 2 Nano-silica powder coated on the outer layer.

[0067] S22: In this embodiment, the outer-coated nano-silicon powder obtained in step S21, 0.02g of coupling agent KH570, and 0.5g of nano-SiO with a diameter of 30nm are selected. 2 The powder and 15g of citric acid were evenly dispersed in the ethanol solution, and after magnetic stirring and dispersion for 60 minutes, the uniformly dispersed suspension was spray-dried at an inlet temperature of 220°C to obtain the precursor of the silicon-carbon composite material.

[0068] S23: Put the precursor of the silicon-carbon composite material in a microwave heating reactor, open the valve of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com