Core-shell structure NdFeB magnetic powder high in electrical resistivity and magnetic performance and application

A high-resistivity, core-shell structure technology, applied to magnetic materials, magnetic objects, circuits, etc., can solve the problems of low performance and low resistivity of high-resistivity magnets, achieve stable magnetic properties, improve corrosion resistance, Effect of reducing eddy current loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

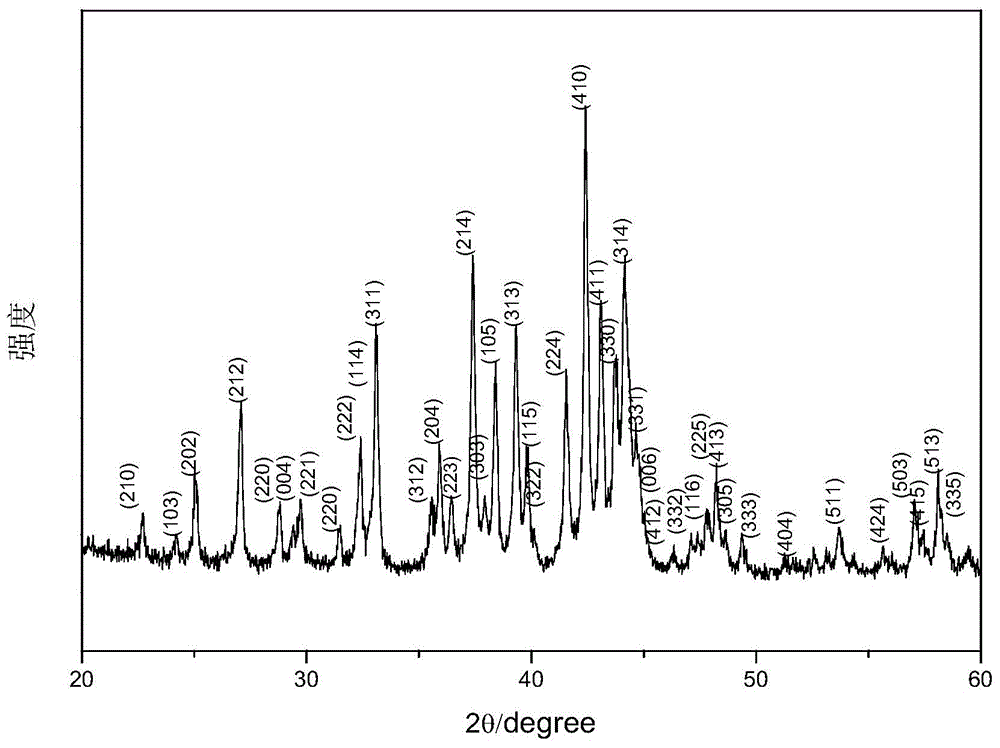

Embodiment 1

[0016] Put the above-mentioned magnetic powder into a tube furnace, firstly evacuate the tube furnace, then feed ammonia gas with a flow rate of 100mL / min, with 10 o C / min heating rate to 300 o C and keep warm for 5 minutes, then cool with the furnace, continue to feed ammonia gas during heat preservation and cool with the furnace, wait until the temperature drops to room temperature, take out the magnetic powder for XRD test, and then prepare it by sintering, bonding or hot pressing magnet. When preparing magnets by bonding, select high-purity epoxy resin as the binder, silane as the coupling agent, and polyamide as the curing agent as the mixed polymer, and then mix the magnetic powder with the above polymer into alcohol , and then stir it with a mixer for 1h, the stirring speed of the mixer is 300~1500r / min, take it out and wait for it to dry and put it under 80 o The temperature field and the magnetic field are formed under the orientation field of 2T, and the molding pr...

Embodiment 2

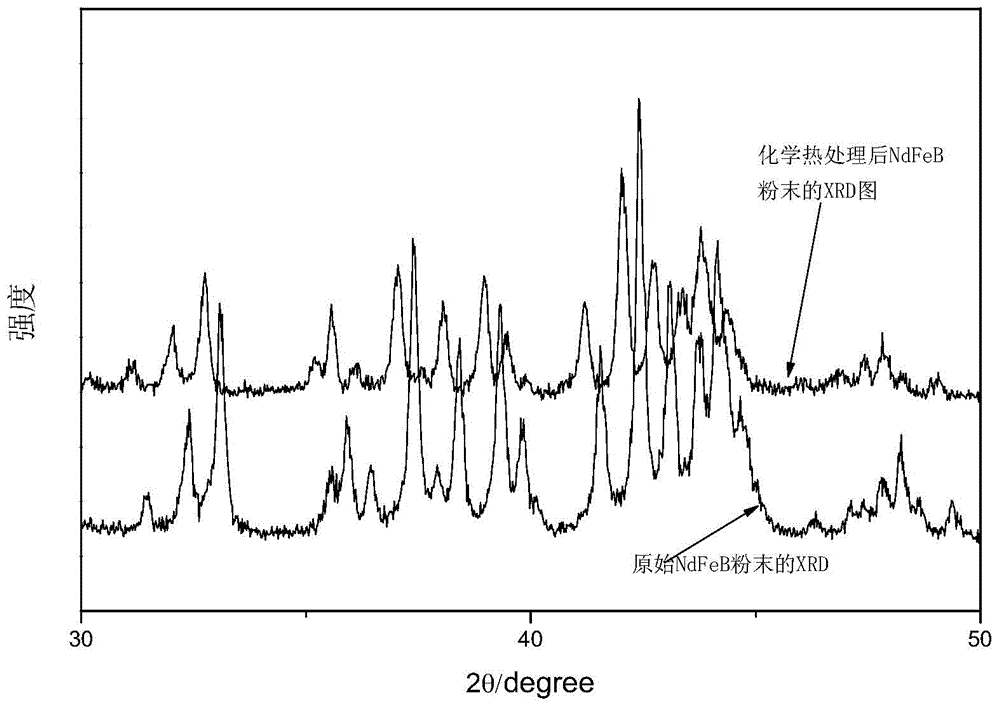

[0018] Put the above-mentioned magnetic powder into a tube furnace, firstly evacuate the tube furnace, then feed ammonia gas with a flow rate of 100mL / min, with 10 o C / min heating rate to 300 o C and keep it warm for 10 minutes, then cool it with the furnace, continue to feed ammonia gas during the heat preservation and cooling with the furnace, wait for the temperature to drop to room temperature, take out the magnetic powder for XRD test. like figure 2 As shown, the overall XRD peak after chemical heat treatment shifted to the left, indicating that the crystal lattice expanded, which was due to the expansion of the lattice due to nitrogen atoms as interstitial atoms. It is then sintered, bonded and hot pressed to make a magnet. When preparing magnets by bonding, select high-purity epoxy resin as the binder, silane as the coupling agent, and polyamide as the curing agent as the mixed polymer, and then mix the magnetic powder with the above polymer into alcohol , and then ...

Embodiment 3

[0020] Put the above-mentioned magnetic powder into a tube furnace, firstly evacuate the tube furnace, then feed ammonia gas with a flow rate of 100mL / min, with 10 o C / min heating rate to 300 o C and keep it warm for 30min, then cool with the furnace, continue to feed ammonia gas during the heat preservation and cool with the furnace, wait until the temperature drops to room temperature, take out the magnetic powder for XRD test, and then prepare it by sintering, bonding and hot pressing magnet. When preparing magnets by bonding, select high-purity epoxy resin as the binder, silane as the coupling agent, and polyamide as the curing agent as the mixed polymer, and then mix the magnetic powder with the above polymer into alcohol , and then stir it with a mixer for 1h, the stirring speed of the mixer is 300~1500r / min, take it out and wait for it to dry and put it under 80 o C The temperature field and the magnetic field are formed under the orientation field of 2T, and the mold...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com