Enhanced perfluorinated ion membrane tape-casting machine

A perfluorinated ion, enhanced technology, applied in dryers, progressive dryers, applications, etc., can solve the problems of long production cycle, waste film, low production efficiency, etc., to save investment costs, easy installation and use, The effect of easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

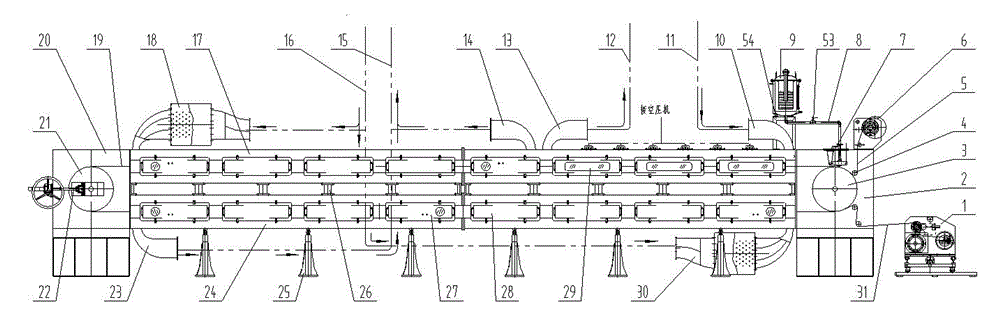

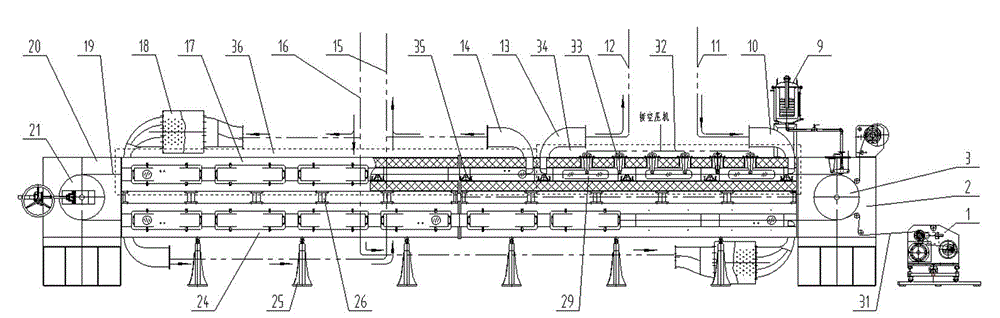

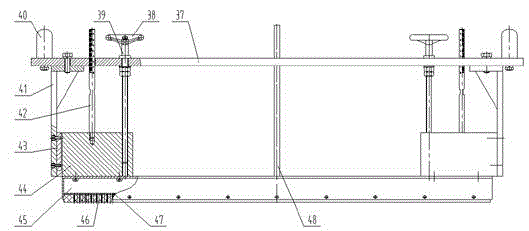

[0021] Such as Figure 1-5 As shown, the tape casting machine includes a winding mechanism 1, a head mechanism 2, a cloth releasing mechanism 6, a casting mechanism 7, a defoamer 9, an upper drying tunnel 17, a lower drying tunnel 24, a steel belt 19, and a tail mechanism 20 and support mechanism 25, on the lower drying passage 24 that a plurality of plug covers 28 and small observation plug covers 27 are housed on both sides, through a plurality of connecting seats 26 and a plurality of plug covers 28, small observation plug covers 27 are housed It is connected with the upper drying channel 17 of the large observation plug cover 29 and is supported by a plurality of supporting mechanisms 25. One end of the upper drying channel 17 and the lower drying channel 24 is connected with a driving roller 3, a casting mechanism 7, and a guide roller. 4 and the machine head mechanism 2 of the cloth releasing mechanism 6, the other end is connected with the tail mechanism 20 of two tight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com