Preparation method of silicon dioxide aerogel

A technology of silica and airgel, applied in chemical instruments and methods, inorganic chemistry, silicon compounds, etc., can solve the problem of not being able to prepare airgel particles that meet the requirements, airgel is not enough to meet the application, air condensation Problems such as high content of glue impurities, etc., achieve the effect of reducing requirements, improving safety performance, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

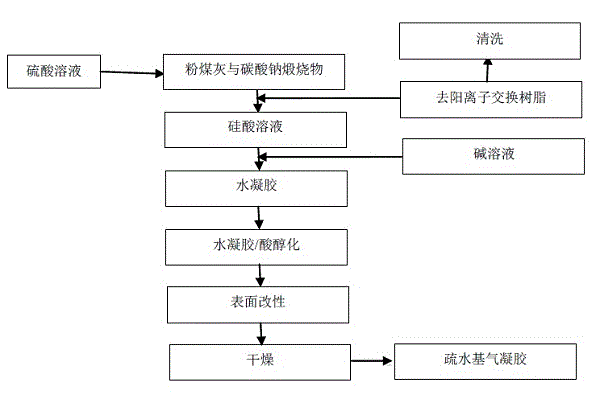

[0037] Such as figure 1 Shown, the preparation method of silica airgel of the present invention, comprises the steps:

[0038] (1) Preparation of sol

[0039] According to the mass ratio of fly ash (or coal gangue): sodium carbonate (or calcium carbonate, potassium carbonate) of 1:0.3~1:0.6, take fly ash and sodium carbonate, mix them and grind them mechanically, at a temperature above 870°C , heat preservation and calcining for 240min~300min to obtain the calcined product;

[0040] According to the ratio of adding 10L~30L sulfuric acid solution per 1Kg calcined product, mix the calcined product with sulfuric acid solution, react at room temperature for 10min~20min, the sulfuric acid concentration is 2mol / l~5mol / l, and pump the reacted material filter to obtain the filtrate, and the filtrate is processed by removing the cation exchange resin, and the resulting solution is adjusted to a pH value of 4~6 or 8~10 by an alkali solution to obtain a silica sol, and the alkali solut...

Embodiment 1

[0057] The preparation method of silica airgel of the present invention, comprises the steps:

[0058] (1) Preparation of sol

[0059] Take fly ash and sodium carbonate according to the mass ratio of fly ash: sodium carbonate of 1:0.3, mix them, grind them mechanically, and heat-preserve and calcinate for 240min at a temperature above 870°C to obtain a calcined product;

[0060] According to the ratio of adding 10L sulfuric acid solution per 1Kg calcined product, mix the calcined product with sulfuric acid solution, react at room temperature for 10min, the sulfuric acid concentration is 2mol / l, suction filter the reacted material to obtain the filtrate, pass the filtrate through Remove the cation exchange resin for treatment, and adjust the pH value of the obtained solution to 4 through an alkali solution to obtain a silica sol. The alkali solution can be a sodium hydroxide solution or a water glass solution.

[0061] 2. Silica sol gelation

[0062] The silica sol was left t...

Embodiment 2

[0070] The preparation method of silica airgel of the present invention, comprises the steps:

[0071] (1) Preparation of sol

[0072] According to the mass ratio of coal gangue: calcium carbonate is 1:0.4, coal gangue and calcium carbonate are taken, mixed, mechanically pulverized, and kept for calcination at a temperature above 870°C for 260min to obtain a calcined product;

[0073] According to the ratio of adding 20L sulfuric acid solution per 1Kg calcined product, mix the calcined product with sulfuric acid solution, react at room temperature for 15min, the sulfuric acid concentration is 4mol / l, suction filter the reacted material to obtain the filtrate, pass the filtrate through Remove the cation exchange resin for treatment, and adjust the pH value of the obtained solution to 6 through an alkali solution to obtain a silica sol. The alkali solution can be a sodium hydroxide solution or a water glass solution.

[0074] 2. Silica sol gelation

[0075] The silica sol was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore size distribution range | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com