Nickel-boron-coated calcium fluoride composite powder, its preparation and application and self-lubricating ceramic tool

A composite powder, calcium fluoride-coated technology, applied in the directions of lubricating compositions, chemical instruments and methods, base materials, etc., can solve problems such as the decline of mechanical properties of ceramic tools, improve low-strength characteristics, increase speed, and difficulty in operation. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

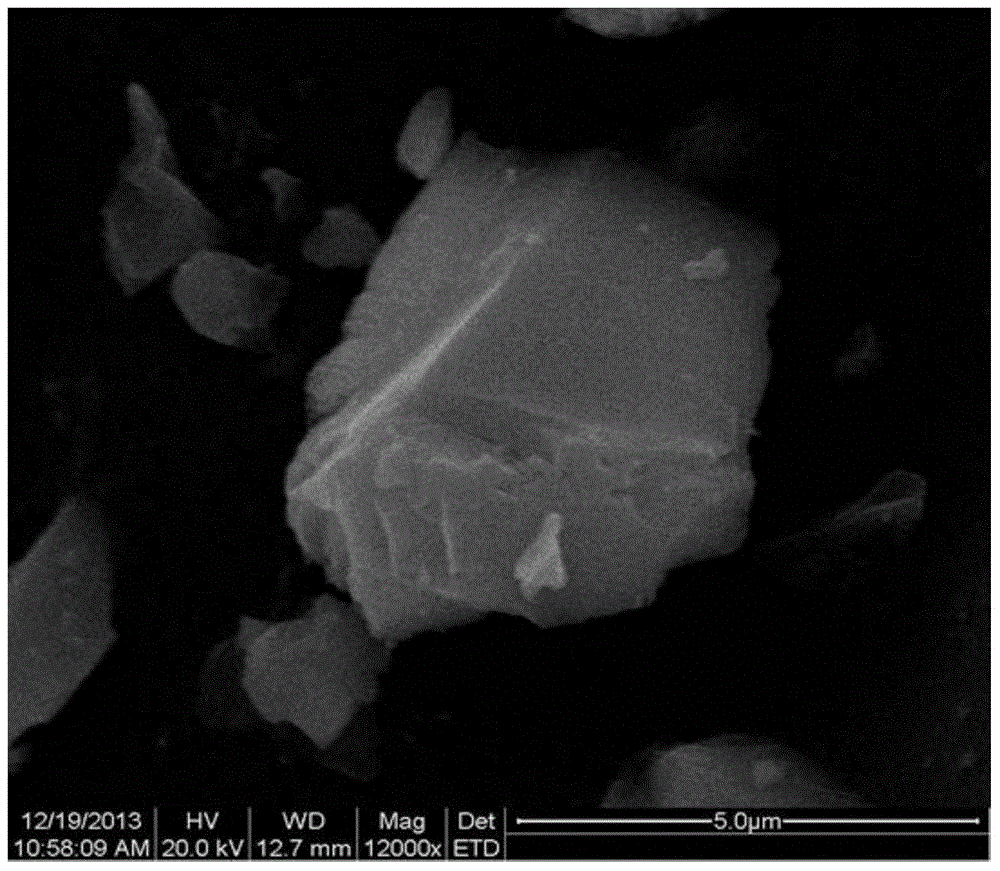

[0046] Example 1: CaF 2 activation of

[0047] (1) Take 2.5gSnCl 2 ·H 2 O is placed in a container, add 4 mL of concentrated hydrochloric acid and stir for 5 min, then add distilled water to a total volume of 200 mL to obtain a sensitized solution; take 15 g of CaF 2 And add it to the sensitization solution, ultrasonically stir for 10min, centrifuge and filter 6 times until the solution is neutral, the speed of the centrifuge is 2600r / min; take out the CaF 2 The suspension is ready for use.

[0048] (2) Take 4mL of concentrated hydrochloric acid in a container, add 0.15g of PdCl 2 , then add distilled water to a total volume of 200mL, the CaF after step (1) sensitization 2 The suspension was added to the container and stirred for 10 min until the suspension completely turned brown.

[0049] (3) Centrifuge the activated suspension at a speed of 3000r / min, centrifuge 7 times, take out the precipitate, and carry out vacuum drying at a vacuum drying temperature of 30°C to ob...

Embodiment 2

[0051] (1) Configure nickel-boron electroless plating solution

[0052] Weigh 1.5g of NiSO 4 ·6H 2 O was dissolved in 20 mL of distilled water, 6 mL of ethylenediamine was added to 50 mL of distilled water, and the NiSO 4 ·6H 2 Pour the O solution into the ethylenediamine solution and stir evenly to obtain the A solution;

[0053] Dissolve 4g of NaOH in 20mL of distilled water, add 0.13g of sodium borohydride, and stir evenly to obtain liquid B;

[0054] Add liquid B to liquid A, and stir evenly; add 0.2 mg of thiourea, stir for about 1 min, add distilled water to make up to a total volume of 100 mL, and the plating solution configuration is completed.

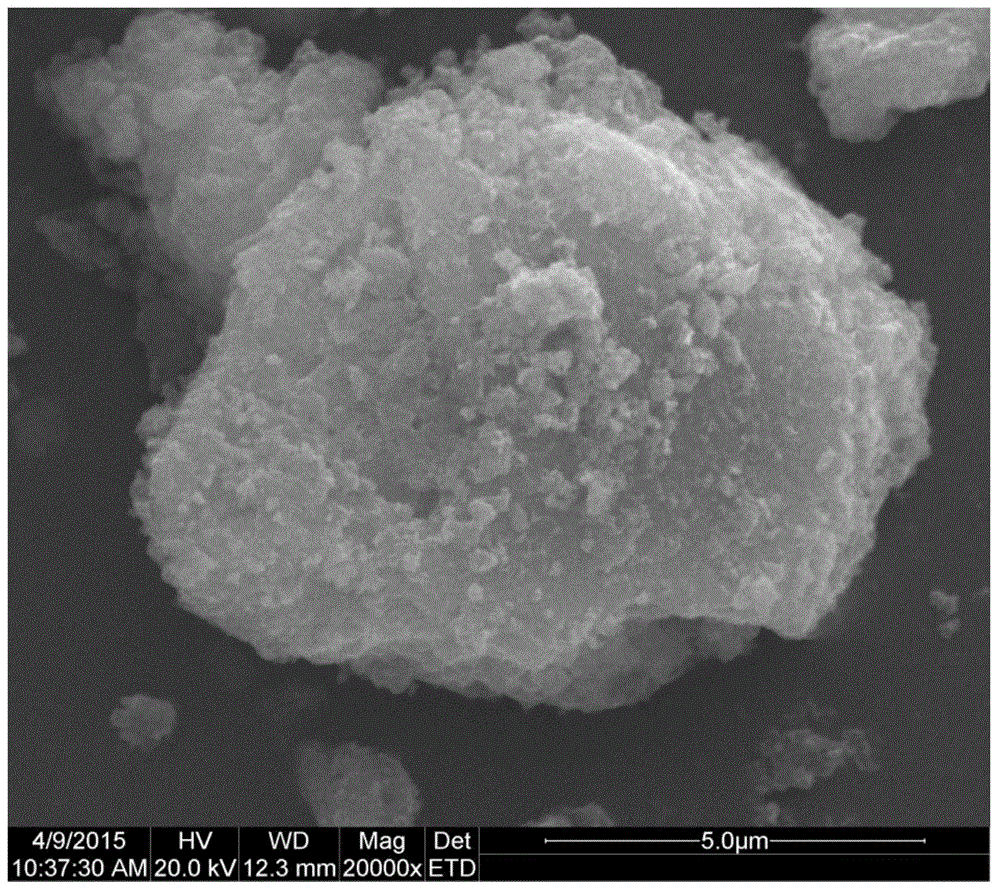

[0055] (2) Take 0.5g CaF that has been activated with a particle size of about 3 μm 2 Add 10mL of distilled water, stir to form a suspension, keep the plating solution prepared in step (1) at about 65°C, and place it in an ultrasonic environment. 2 The suspension was poured into the plating solution for plating. During t...

Embodiment 3

[0059] (1) Weigh 1.0g of NiSO 4 ·6H 2 O and dissolve it in 20ml of distilled water, take 5mL of ethylenediamine and add to 50mL of distilled water, NiSO 4 ·6H 2 Pour O solution into ethylenediamine and stir evenly to obtain liquid A; take 4g NaOH and dissolve it in 30ml of distilled water, add 0.15g sodium borohydride and stir evenly to obtain liquid B; add liquid B to liquid A Add 0.1 mg of thiourea to the mixed solution of A and B solutions and stir slowly, and the plating solution configuration is completed.

[0060] (2) Adjust the temperature of the plating solution to about 55°C, and take the activated CaF with a particle size of about 5 μm 2 0.5g, pour it into 10ml of distilled water, stir to form a suspension, place the plating solution in an ultrasonic environment, and 2 The suspension was poured into the plating solution for ultrasonic electroless plating, and the stirring speed was set to 60r / min, and the plating was terminated when no bubbles emerged.

[0061] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com