SAPO-34 molecular sieve of larger specific surface area and hollow alumina-rich hierarchical pore structures and application thereof

A technology of SAPO-34 and specific surface area, which is applied in the field of molecular sieves, can solve the problems of troublesome post-processing methods, low silicon content, and limited application, and achieve the effects of reducing waste liquid pollution, high selectivity, and low solvent consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

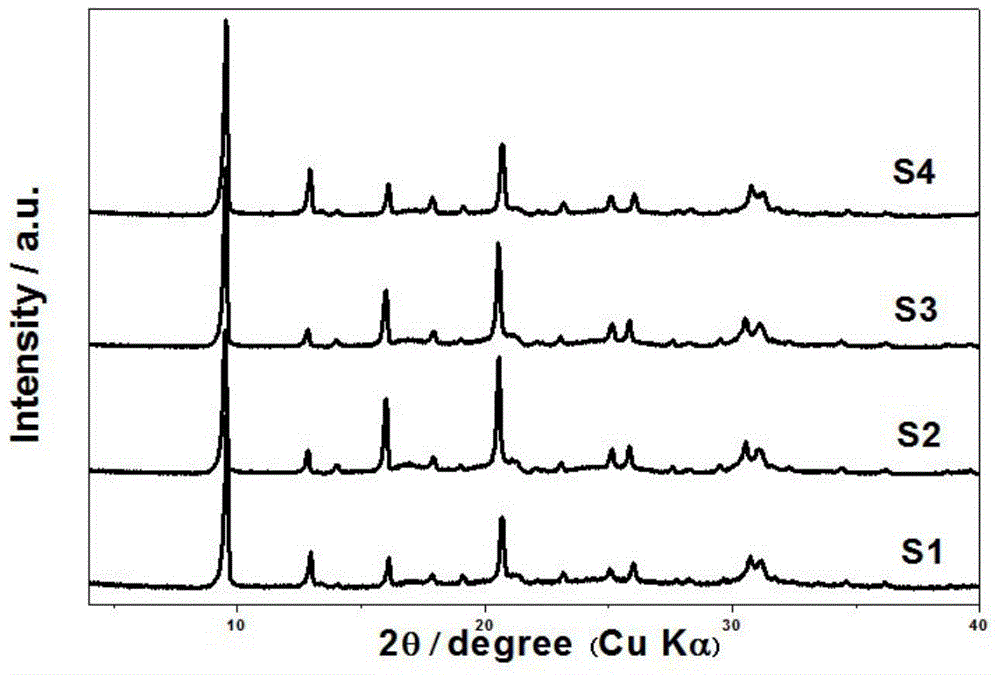

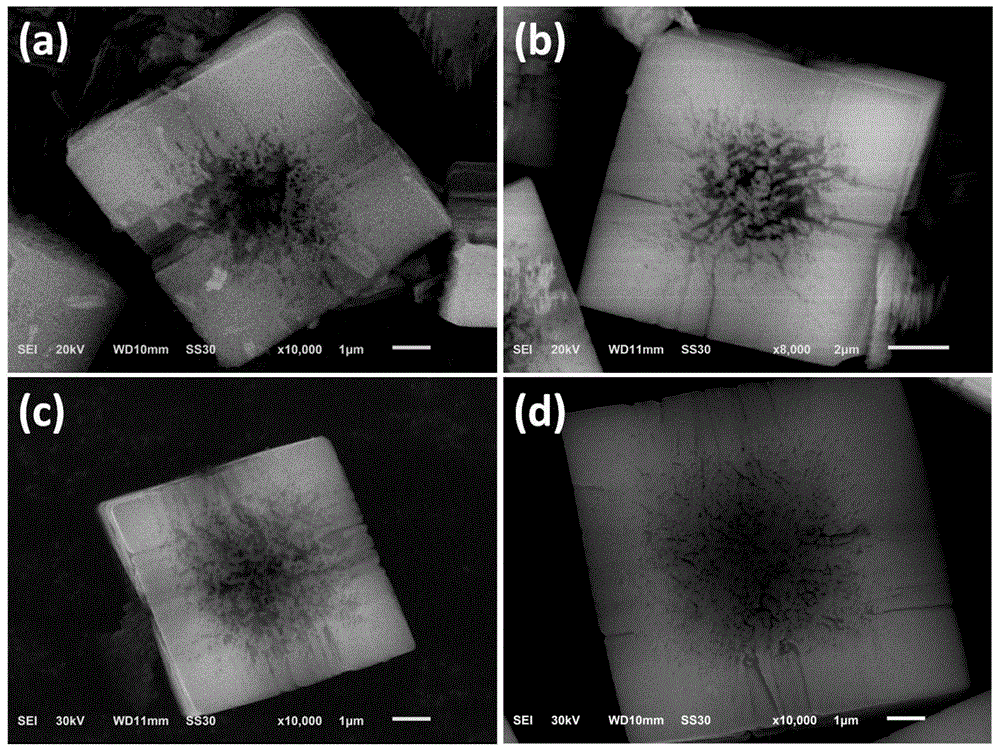

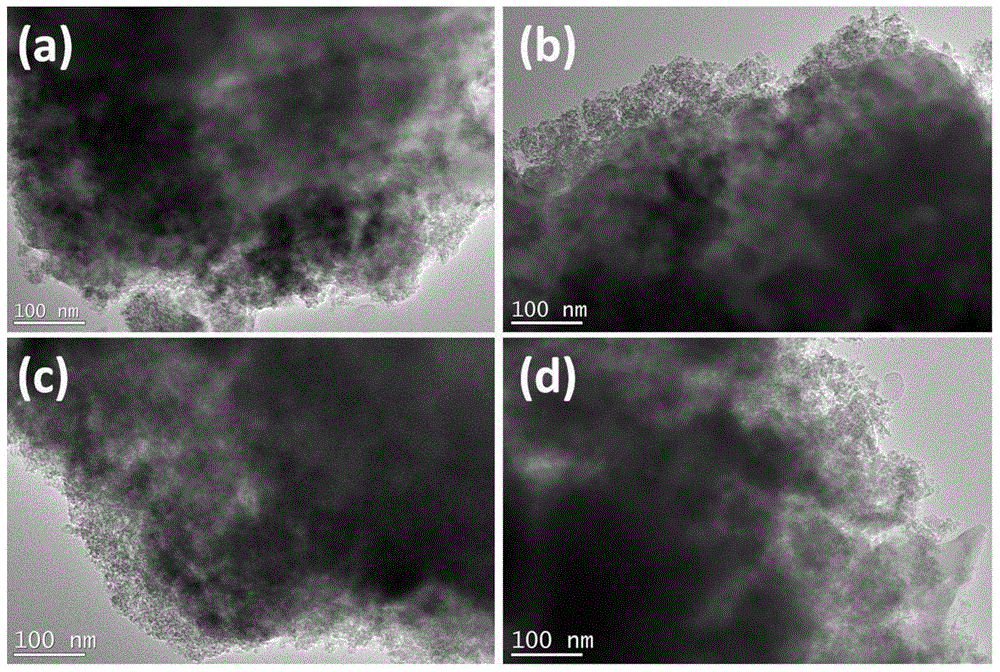

Embodiment 1

[0043] Mix and stir aluminum isopropoxide, water, triethylamine and polyethylene glycol 400 (PEG 400) thoroughly, then stir at 30°C for 5 hours to obtain a mixture; add white carbon black and phosphoric acid to the above mixture in turn, and keep stirring Treat for 2 hours to obtain the initial gel mixture of SAPO-34 molecular sieve; afterward, stir the initial gel mixture of SAPO-34 molecular sieve obtained in a water bath at 50°C for another 3 hours, and the initial gel mixture of each component in the reaction system The molar ratio is 5TEA:0.3SiO 2 : 1.0P 2 o 5 : 8Al 2 o 3 : 58.4H 2 O: 0.05PEG 400; put the initial gel mixture into a stainless steel reaction kettle with polytetrafluoroethylene lining, then put the reaction kettle in an oven, raise the temperature to 180 ° C, under autogenous pressure, under hydrothermal conditions Constant temperature (180°C) crystallization for 18 hours. Then, the solid product was separated by centrifugation, washed repeatedly with ...

Embodiment 2

[0045] Mix pseudo-boehmite, water, methanol (MeOH), triethylamine, and polyethylene glycol 2000 thoroughly and stir at 50°C for 8 hours to obtain a mixture; add active silica and phosphoric acid to the above mixture in sequence During the stirring process for 2 hours, the initial gel mixture of SAPO-34 molecular sieves was obtained; after that, the initial gel mixture of SAPO-34 molecular sieves was stirred for another 2 hours in a water bath at 80°C, and the initial gel mixture in the reaction system was The molar ratio of each component is 10TEA:0.8SiO 2 : 1.0P 2 o 5 : 4Al 2 o 3 : 200H 2 O: 40MeOH: 0.5PEG 2000; put the initial gel mixture into a stainless steel reactor with a polytetrafluoroethylene liner, then place the reactor in an oven, raise the temperature to 230 ° C, under autogenous pressure, hydrothermal conditions Crystallization at a constant temperature (230°C) for 6 hours. Then, the solid product was separated by centrifugation, washed repeatedly with deio...

Embodiment 3

[0047] Mix aluminum oxide, ethanol (EtOH), triethylamine and polyethylene glycol 1000 thoroughly and stir at 40°C for 5 hours to obtain a mixture; add ethyl silicate and phosphoric acid to the above mixture in turn, and continue stirring Treat for 5 hours to obtain the initial gel mixture of SAPO-34 molecular sieve; after that, stir the obtained initial gel mixture of SAPO-34 molecular sieve in a water bath at 60°C for another 8 hours, and the components in the initial gel mixture in the reaction system are oxidized The molar ratio of substance, triethylamine and solvent is 7TEA:0.1SiO 2 : 1.0P 2 o 5 : 8Al 2 o 3 : 20EtOH: 0.2PEG 1000; put the initial gel mixture into a stainless steel reaction kettle with polytetrafluoroethylene lining, then put the reaction kettle in an oven, heat up to 200 ° C, under autogenous pressure, under hydrothermal conditions Constant temperature (200° C.) crystallization was carried out for 20 hours. Then, the solid product is centrifuged, wash...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com