Flexible surface acoustic wave device resistant to high temperature and manufacturing method thereof

A surface acoustic wave device, high temperature resistant technology, used in electrical components, impedance networks and other directions, can solve the problems of surface acoustic wave device influence, softening, melting, decomposition, inability to fold, bend, etc., to improve the center frequency, quality Light, inexpensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

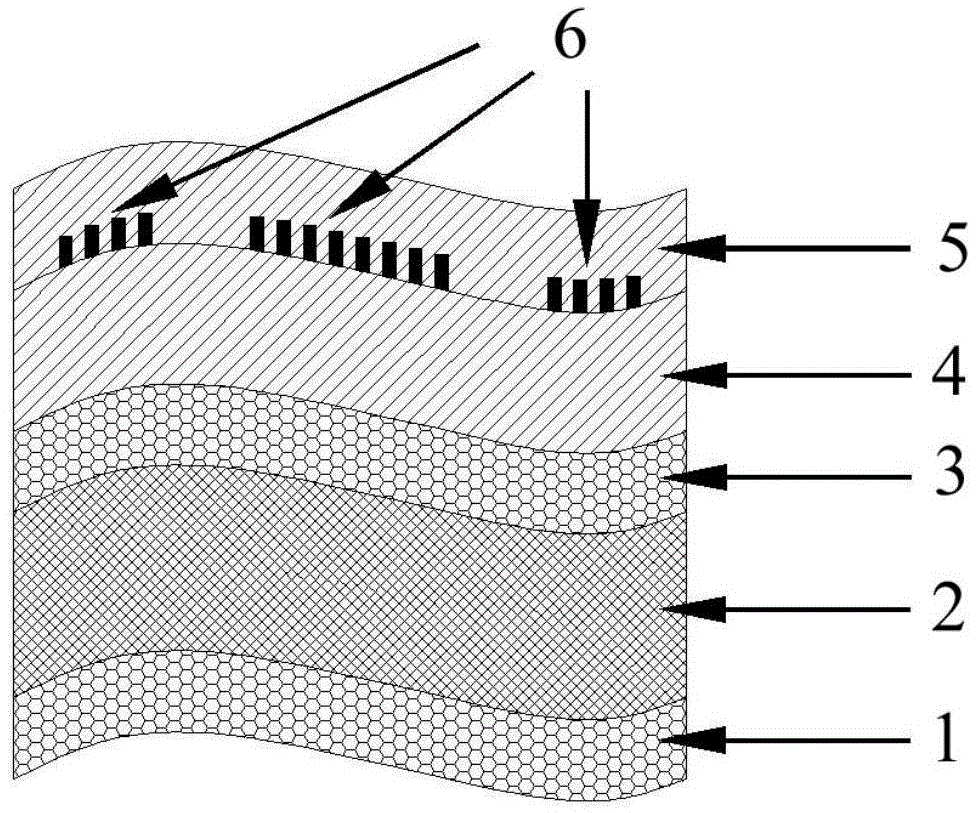

[0027] Step 1. Pretreatment of the flexible alloy substrate: select high-temperature nickel-based Hastelloy C-276 as the flexible alloy material, and cut the flexible alloy material into a thickness of 100 μm and a size of 20 mm×10 mm. Electrochemical polishing is performed on the flexible alloy substrate to polish, passivate and remove metal burrs on the surface of the alloy strip. Use a mixed solution of alcohol and acetone to ultrasonically clean both sides of the alloy strip twice. Put the cleaned flexible Hastelloy substrate into an oven filled with pure nitrogen and heat it to 100°C for 1 hour.

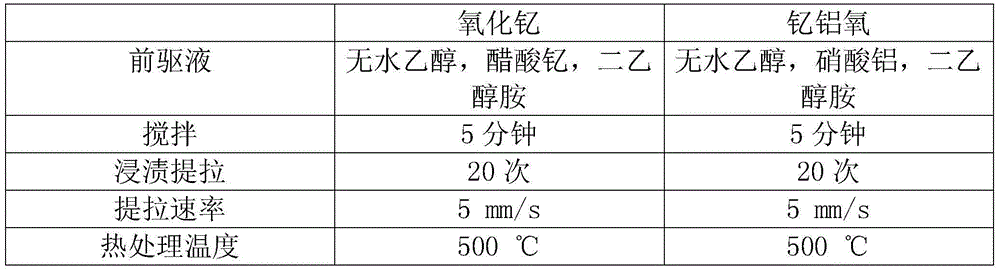

[0028] Step 2. Preparation of the buffer layer and the bottom protective layer: a layer of yttrium oxide (Yttrium oxide (Y 2 o 3 ) or yttrium aluminum oxide (Y 2 o 3 -Al 2 o 3 ) amorphous oxide film, the specific parameters are shown in the table below.

[0029]

[0030] Step 3, the preparation of aluminum nitride piezoelectric thin film: the aluminum nitride piezoelec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com