Nickel and manganese blended lithium ion battery positive material and preparation method thereof

A positive electrode material and ion battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as potential safety hazards, explosion of lithium-ion batteries, and increased chaos of positive electrode materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

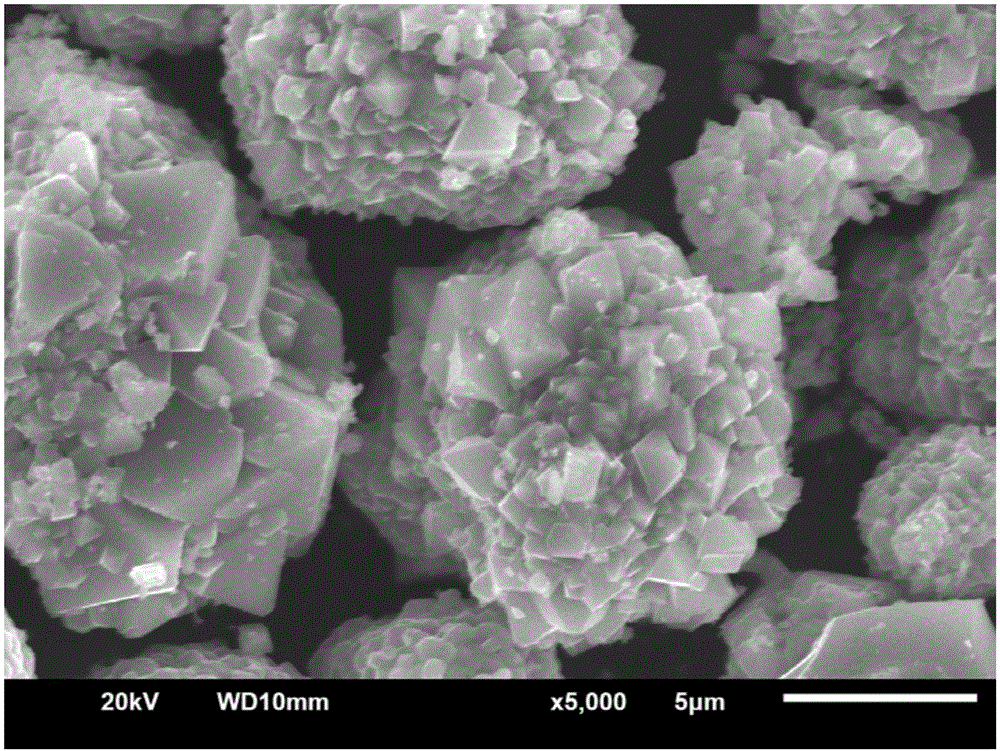

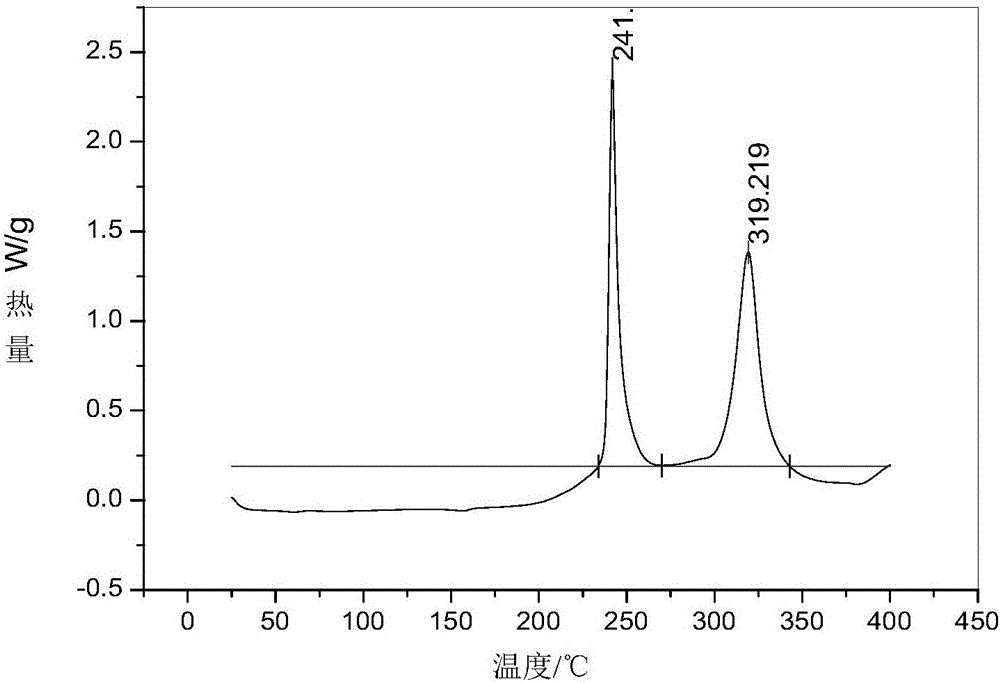

[0088] (1) According to the combination of 10.1mol lithium hydroxide and 10mol (based on the sum of the molar quantity of nickel element, cobalt element and manganese element) nickel cobalt manganese hydroxide Ni 0.7 mn 0.15 co 0.15 (OH) 2 Mix ball milling for 1 hour, roast at 300°C for 5 hours, cool naturally to 25°C, grind the material through a 100-mesh sieve, then roast at 900°C for 20 hours, cool to 25°C naturally, wash once with deionized water, and pulverize to The D50 particle size is 20 μm, and the nickel-cobalt lithium manganese oxide ternary cathode material LiNi is obtained 0.7 mn 0.15 co 0.15 o 2 .

[0089] (2) 10mol of LiNi prepared in step 1 0.7 mn 0.15 co 0.15 o 2 The positive electrode material was mixed with 30 mol of lithium manganese oxide ball milled for 2 hours to prepare the positive electrode material of the lithium ion battery.

[0090] The measured pH value of the positive electrode material of the lithium ion battery is 10.64, and the resi...

Embodiment 2

[0095] (1) According to 10.2mol lithium nitrate and 10mol (based on the sum of the molar quantity of nickel element, the molar quantity of cobalt element and the molar quantity of aluminum element) nickel cobalt aluminum hydroxide Ni 0.8 co 0.15 Al 0.05 (OH) 2 Disperse in ethanol, stir and filter to remove ethanol, dry the obtained solid, then roast at 500°C for 10h, cool naturally to 30°C, pulverize until the D50 particle size is 20μm, then roast at 800°C for 12h, and cool naturally to 25°C, washed 3 times with ethanol, and crushed to a D50 particle size of 18 μm to obtain the nickel-cobalt lithium manganate ternary cathode material LiNi 0.8 co 0.15 Al 0.05 o 2 .

[0096] (2) 10mol of LiNi prepared in step 1 0.8 co 0.15 Al 0.05 o 2 The positive electrode material was mixed with 20 mol of lithium manganate ball milled for 1 hour to prepare the positive electrode material of the lithium ion battery.

[0097] The measured pH value of the positive electrode material of...

Embodiment 3

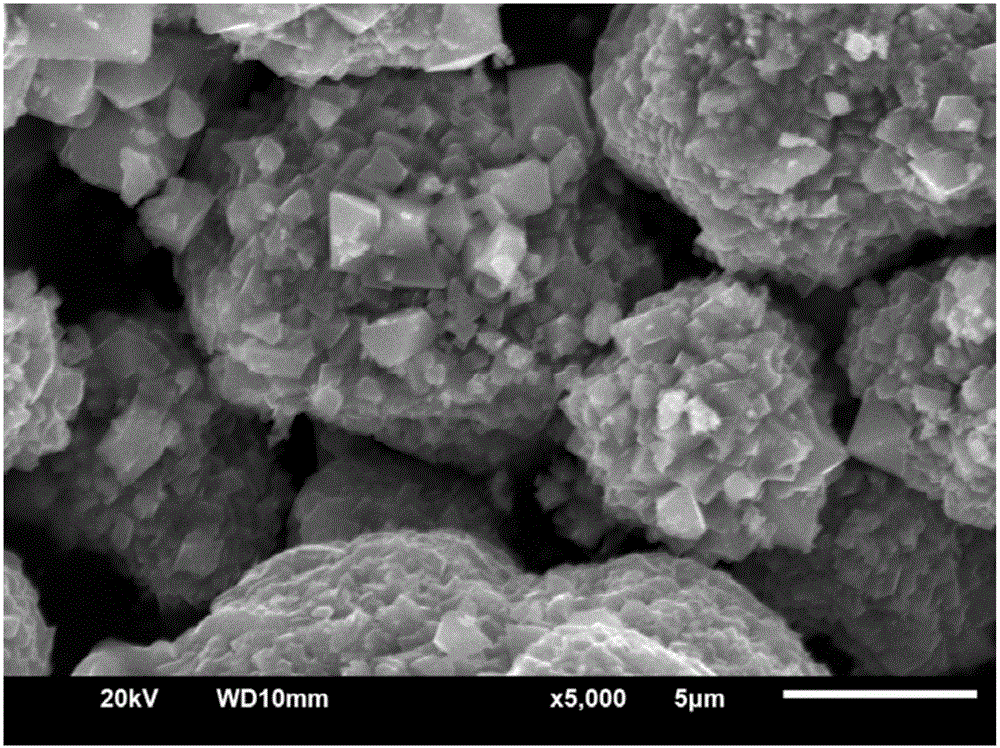

[0102] (1) According to the combination of 10.4mol lithium hydroxide and 10mol (based on the sum of the molar quantity of nickel element, the molar quantity of cobalt element and the molar quantity of manganese element) nickel cobalt manganese hydroxide Ni 0.8 co 0.1 mn 0.1 (OH) 2 Disperse in ethanol, stir and filter to remove ethanol, dry the obtained solid, then roast at 600°C for 2h, cool naturally to 20°C, pulverize until the D50 particle size is 22μm, then roast at 1000°C for 15h, and cool naturally to 20°C, washed 3 times with high-purity water, and crushed to a D50 particle size of 15 μm to obtain the nickel-cobalt lithium manganate ternary cathode material LiNi 0.8 co 0.1 mn 0.1 o 2 .

[0103] (2) 10mol of LiNi prepared in step 1 0.8 co 0.1 mn 0.1 o 2 The positive electrode material was mixed with 40 mol of lithium manganate ball milled for 0.5 h to obtain the positive electrode material of the lithium ion battery.

[0104] The measured pH value of the posit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com