Composite magnetic nano-particle adsorbent and preparation method and application thereof

A magnetic nanoparticle and composite magnetic technology, applied in separation methods, chemical instruments and methods, adsorbed water/sewage treatment, etc., can solve the problems of insufficient adsorption of macromolecular dyes, difficulty in harmless treatment, and limited use range, etc. Achieve ideal adsorption effect, easy operation, high recovery rate and regeneration rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1: Preparation of magnetic ferroferric oxide nanoparticles

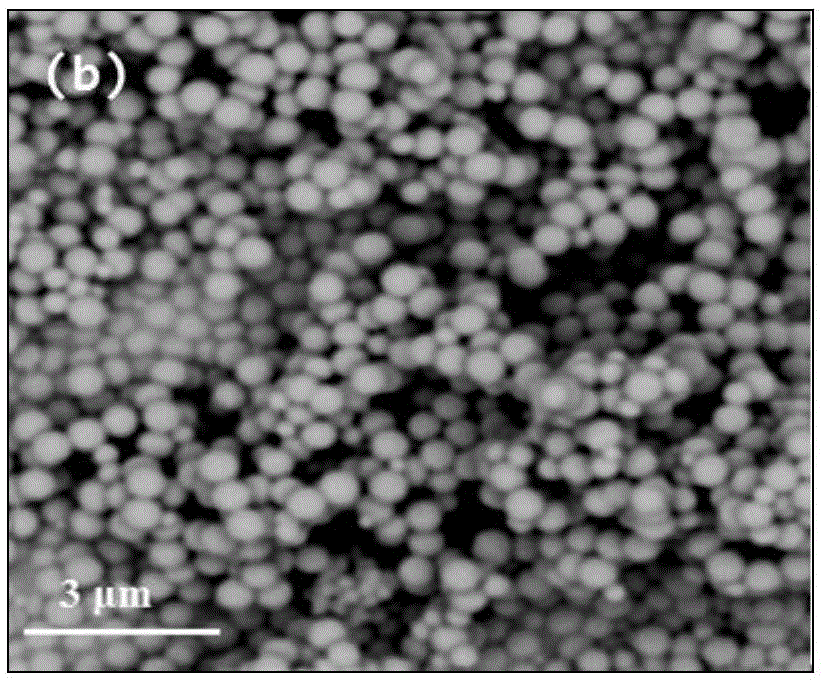

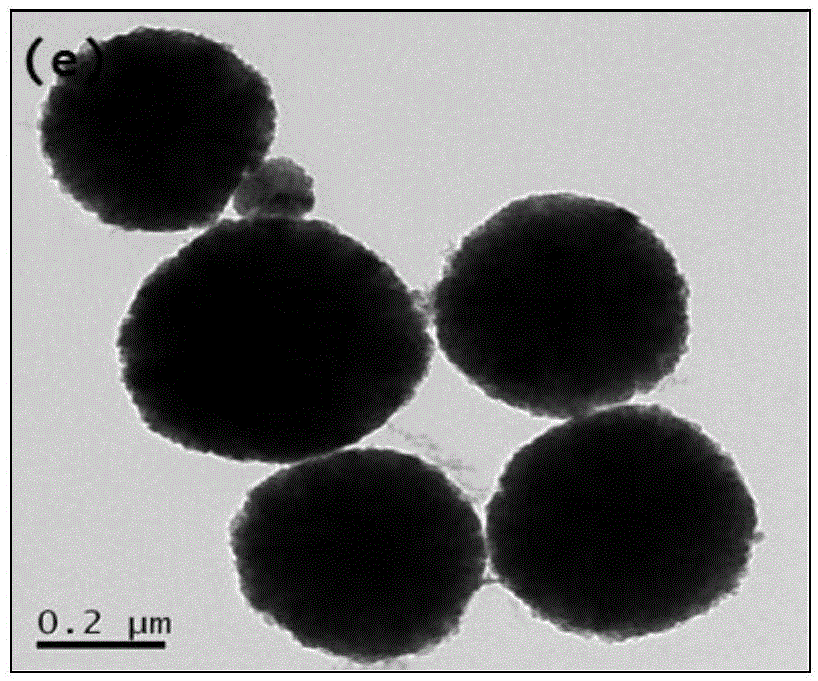

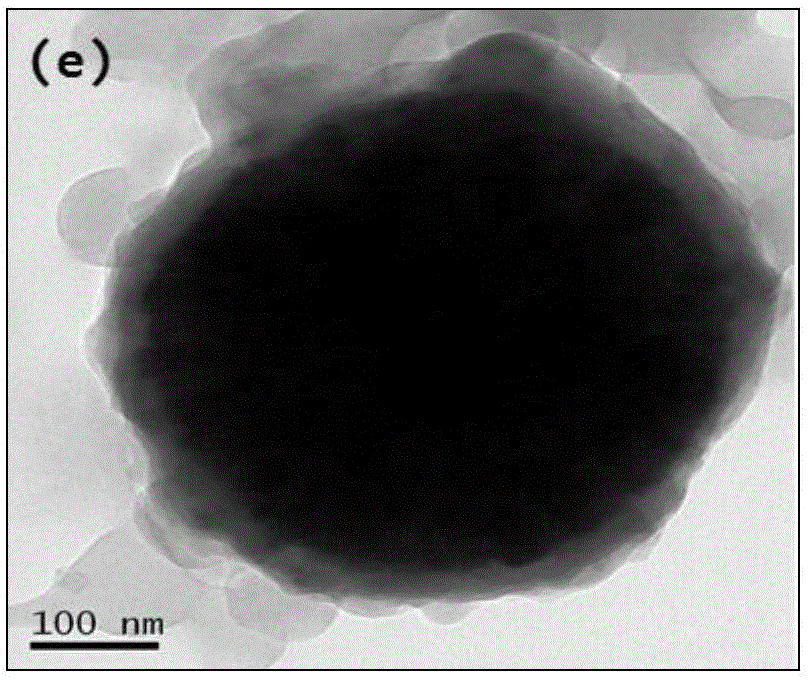

[0035] 3.5g ferric chloride hexahydrate (FeCl 3 ·6H 2 O) Add 80 mL of ethylene glycol and ultrasound to completely dissolve it, then add 7.2 g of sodium acetate (NaAc) and 2.0 g of polyethylene glycol 2000 (PEG 2000), and heat and stir at 50° C. for 0.5 h. Then transfer the reaction solution to a 100mL autoclave, and react for a certain time from room temperature to 200°C for 6 hours. After the reaction is completed, it is ultrasonically cleaned with absolute ethanol several times, magnetically separated, and dried in a vacuum drying oven at 50°C for 24 hours to obtain magnetic tetroxide. Tri-iron nanoparticles A, figure 1 , figure 2 These are the scanning electron microscope and transmission electron microscope images of Fe3O4 nanoparticles.

Embodiment 2

[0036] Example 2: Preparation of magnetic ferroferric oxide nanoparticles

[0037] 4.5g ferric chloride hexahydrate (FeCl 3 ·6H 2 O) Add 80 mL of ethylene glycol and ultrasound to completely dissolve it, then add 7.2 g of sodium acetate (NaAc) and 2.0 g of polyethylene glycol 2000 (PEG 2000), and heat and stir at 50°C for 1 hour. Then the reaction solution was transferred to a 100mL autoclave, and reacted for a certain period of 8 hours from room temperature to 200°C. After the reaction, it was washed several times with absolute ethanol ultrasonically, magnetically separated, and dried in a 60°C vacuum drying oven for 24 hours to obtain magnetic tetroxide. Three iron nanoparticles B.

Embodiment 3

[0038] Example 3: Preparation of magnetic ferroferric oxide nanoparticles

[0039] 2.5g ferric chloride hexahydrate (FeCl 3 ·6H 2 O) Add 80 mL of ethylene glycol and ultrasound to completely dissolve it, then add 7.2 g of sodium acetate (NaAc) and 2.0 g of polyethylene glycol 2000 (PEG 2000), and heat and stir at 50°C for 1 hour. Then transfer the reaction solution to a 100mL autoclave, and react for a certain time from room temperature to 200°C for 6 hours. After the reaction is completed, it is washed with absolute ethanol for several times, magnetically separated, and dried in a vacuum drying oven at 60°C for 28 hours to obtain magnetic tetroxide. Three iron nanoparticles C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com