Nano liquid for decompression and augmented injection of tight oil water-flooding and preparation method and application thereof

A dense oil, hydrophobic nanotechnology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of high cost, application limitation, environmental pollution, etc., and achieve the effects of low cost, convenient preparation and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Embodiment 1: the preparation of hydrophobic nano silicon dioxide

[0049] Put 6g of nano-silica in a three-necked flask, stir and dry in an oil bath at 100-120°C for 1-3h, remove the moisture on the surface of nano-silica; cool down to 50°C, add 150g of absolute ethanol, and continue stirring 20min, to form a uniform dispersion of nano-silica; add 0.3g dimethyl dichlorosilane modifier and 0.15g water, adjust the oil bath temperature to 75-80°C, and react with nitrogen for 4h; centrifuge the reaction solution, And wash the precipitate 4-6 times with absolute ethanol to remove the residue; dry the washed precipitate in a vacuum drying oven at 100° C. for 24 hours, and grind to obtain hydrophobically modified nano silicon dioxide.

Embodiment 2

[0050] Example 2: The development of tight oil water injection nano-fluid for pressure reduction and injection increase, the composition of the raw materials is as follows:

[0051] The hydrophobic nano silicon dioxide 2g that embodiment 1 prepares,

[0052] Dispersant PEG600 4g,

[0053] Dispersion aid NaOH 1g,

[0054] Water 993g.

[0055] Preparation steps:

[0056] Take 4g of dispersant PEG600 and add it to 993g of water, stir mechanically at room temperature for 5min, after stirring evenly, add 2g of modified hydrophobic nano-silica, add 1.0g of dispersing aid NaOH at the same time, continue stirring for 5min, and continue to mix in a water bath at 60°C Stir the mixed solution for 20 minutes to obtain the depressurized and increased injection nano-liquid.

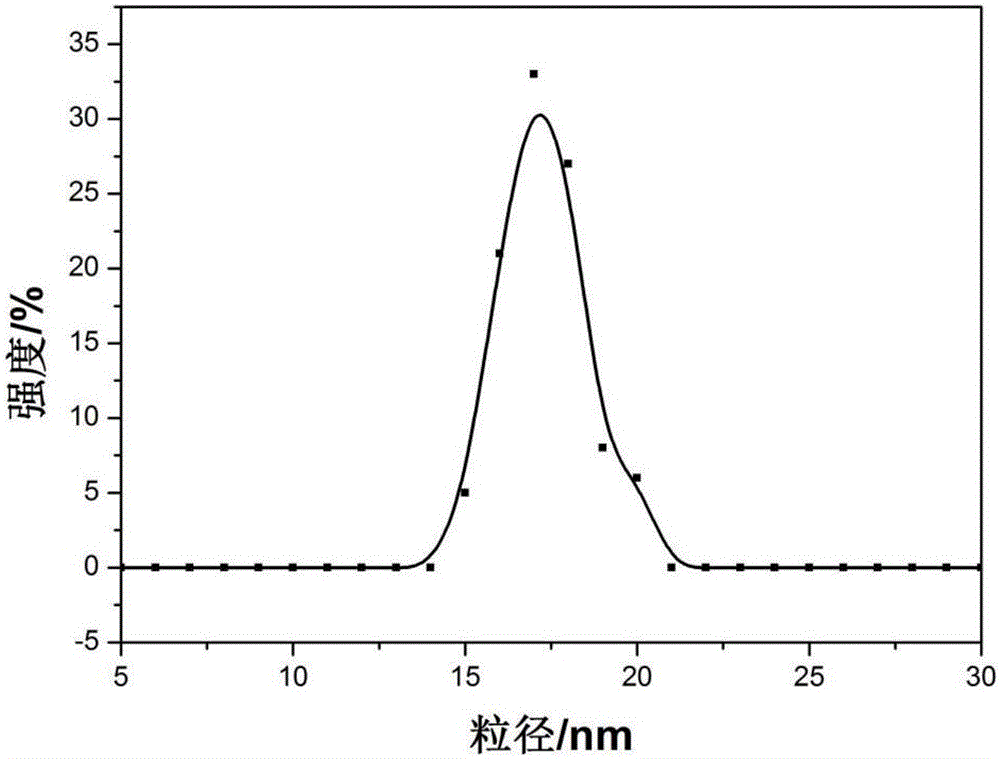

[0057] The particle size distribution of hydrophobic nano-silica in the gained step-down and increase-injection nano-liquid is as follows: figure 1 As shown, the particle size is between 14-21nm, and the median part...

Embodiment 3

[0058] Example 3: The development of tight oil water injection nano-fluid for depressurization and increasing injection, the composition of the raw materials is as follows:

[0059] The hydrophobic nano silicon dioxide 3.5g that embodiment 1 prepares,

[0060] Dispersant PEG600 6g,

[0061] Dispersion aid NaOH 1.5g,

[0062] Water 989g.

[0063] The preparation steps are the same as in Example 2, except that the mixed solution is continuously stirred for 20 minutes under the condition of a 65°C water bath to obtain the reduced-pressure and increased-injection nano-liquid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com