Aramid fiber surface modification method

A technology for surface modification of aramid fibers, applied in fiber types, fiber treatment, textiles and papermaking, etc., can solve the problems of surface inertia of aramid fibers and poor bonding of resin matrix, so as to improve surface inertia and reduce modification costs , Improve the effect of roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0018] Specific implementation mode one: a method for modifying the surface of aramid fibers in the present implementation mode is specifically carried out according to the following steps:

[0019] 1. Put the aramid fiber bundle into the extraction device, extract it with acetone for 16-48 hours, and then dry it in an oven at a temperature of 60-80°C for 1-3 hours to obtain the aramid fiber after desizing treatment;

[0020] 2. Add the acyl chloride reagent and the aramid fibers processed in step 1 to the glass reactor, close the reactor, and then place 60 Carry out γ-ray irradiation treatment under the Co irradiation source; then take out the aramid fiber, put it into the extraction device, and extract it with N,N-dimethylformamide for 2 to 4 hours; then put it into an oven with a temperature of 150°C Medium drying for 1 to 3 hours;

[0021] 3. Immerse the aramid fibers treated in step 2 in the grafting reagent, react at room temperature and pressure for 0.1-3 hours; then r...

specific Embodiment approach 2

[0022] Specific embodiment two: the difference between this embodiment and specific embodiment one is: adopt acetone to extract 24h in step one. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0023] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the acyl chloride reagent in step two is thionyl chloride, oxalyl chloride, sulfuryl chloride, isophthaloyl dichloride, terephthaloyl dichloride, propane One or more of diacid chloride, succinoyl chloride, glutaryl chloride and adipoyl chloride are mixed in any ratio. Others are the same as in the first or second embodiment.

PUM

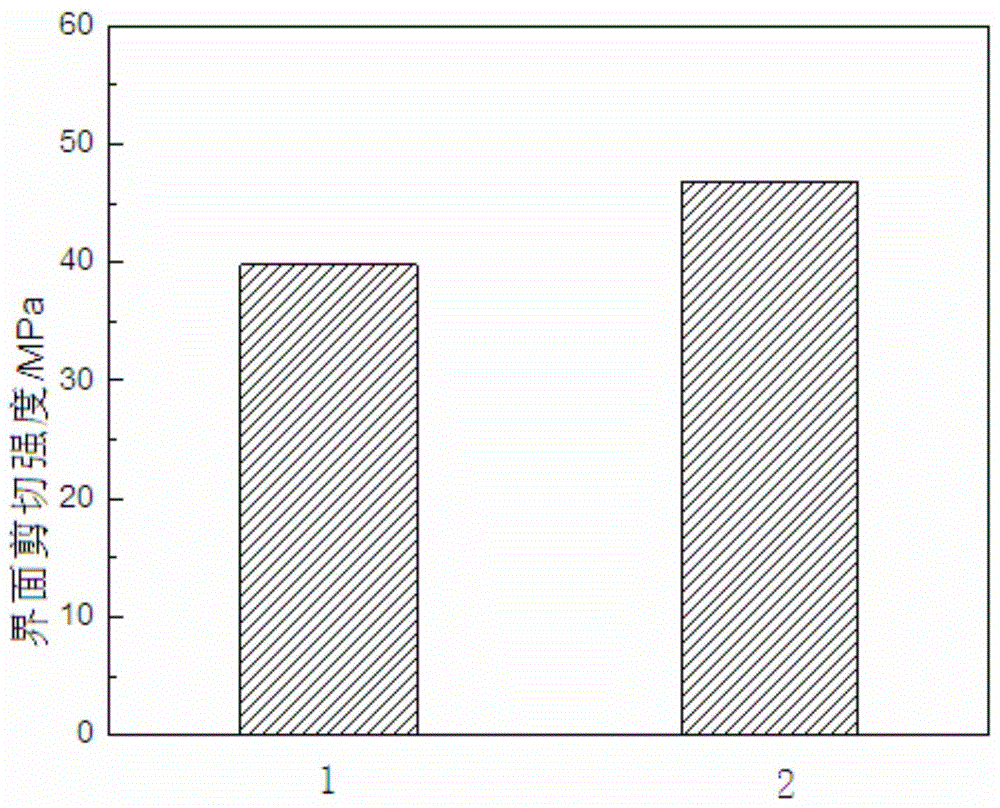

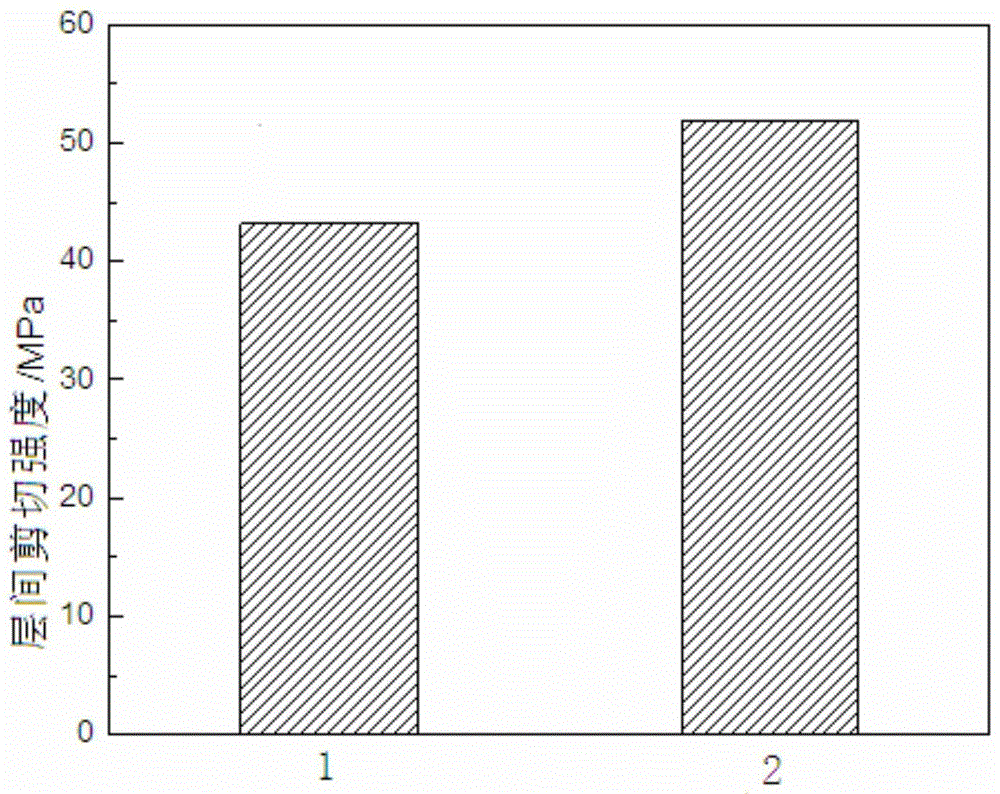

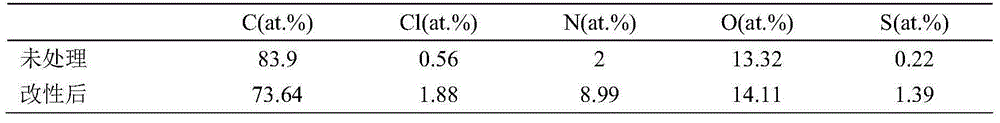

| Property | Measurement | Unit |

|---|---|---|

| Shear strength | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com