Polymer embedded metal organic framework membrane, preparation method, device and application thereof

A metal-organic framework and polymer technology, applied in separation methods, chemical instruments and methods, membrane technology, etc., can solve the problems of poor gas separation effect, low utilization rate of raw materials, low selectivity, etc., to reduce energy, improve Harness the effect of efficiency, simplifying synthesis and modification steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The preparation of embodiment 1 metal organic framework ZIF-8 film

[0030] (1) Cut out a polyvinylidene fluoride hollow fiber membrane with a length of 6 cm, place it in a 30 wt % aqueous solution of ethylenediamine, seal it under the condition of 100 ° C for 12 h, take out the membrane after natural cooling, and use After washing with ion water for three times and drying, it is packaged in a cross-flow membrane module to form a hollow fiber membrane module.

[0031] (2) Preparation of metal-organic framework precursor solution: 2-methylimidazole (0.21g, 2.5mmol) and Zn(NO 3 ) 2 ·6H 2 O (0.37g, 1.25mmol) was dissolved in 1000ml deionized water respectively to obtain 2-methylimidazole solution and Zn(NO 3 ) 2 solution.

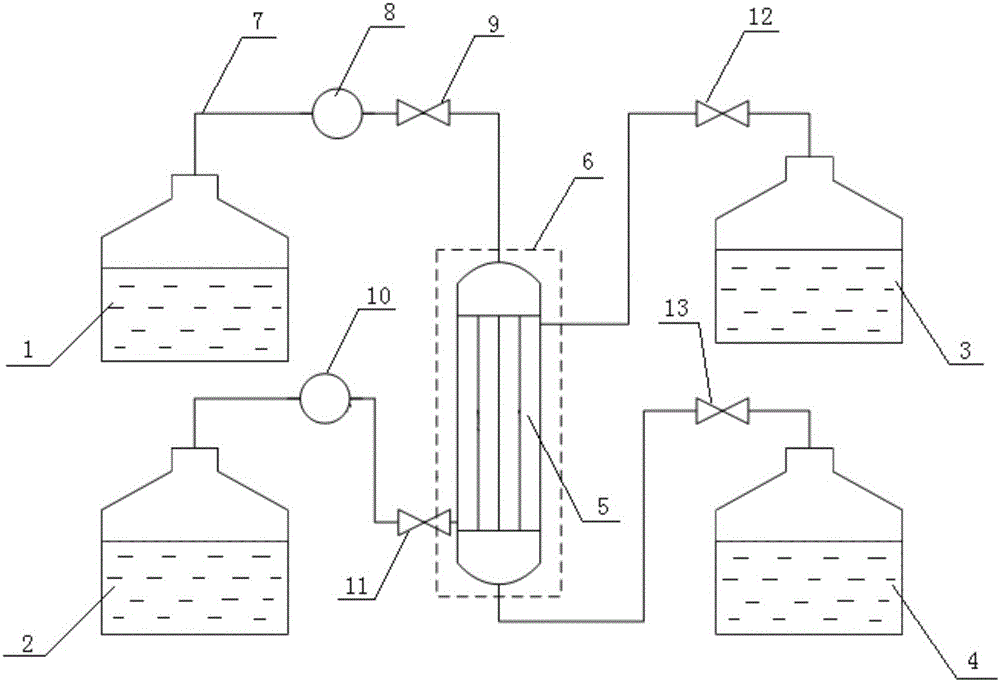

[0032] (3) Preparation of membrane: the heater outside the hollow fiber membrane module 5 is preset at 30°C, and the 2-methylimidazole solution obtained in step (2) and Zn(NO 3 ) 2 The solution is respectively placed in the first feed tank 1 and ...

Embodiment 2

[0034] Example 2 Preparation of metal-organic framework ZIF-8 film embedded in polyvinyl alcohol

[0035] (1) Cut a 6cm-long polyvinylidene fluoride hollow fiber membrane, place it in a 30wt% aqueous solution of ethylenediamine, seal it at 100°C for 12h, take out the membrane after natural cooling, and wash it with water After three times of drying, it is packaged in a cross-flow membrane module to form a hollow fiber membrane module.

[0036] (2) Preparation of metal-organic framework precursor solution: 2-methylimidazole (0.21g, 2.5mmol) and Zn(NO 3 ) 2 ·6H 2 O (0.37g, 1.25mmol) was dissolved in 1000ml of deionized water respectively, and 0.5g polyvinyl alcohol was added in the 2-methylimidazole solution to obtain a 2-methylimidazole solution containing polyvinyl alcohol and Zn(NO 3 ) 2 solution.

[0037] (3) Preparation of membrane: the heater outside the hollow fiber membrane module 5 is preset at 60°C, and the 2-methylimidazole solution containing polyvinyl alcohol o...

Embodiment 3

[0039] Example 3 Preparation of metal-organic framework ZIF-8 film embedded with polyethylene glycol

[0040] (1) Cut a 6cm-long polyvinylidene fluoride hollow fiber membrane, place it in a 30wt% aqueous solution of ethylenediamine, seal it at 100°C for 12h, take out the membrane after natural cooling, and wash it with water After three times of drying, it is packaged in a cross-flow membrane module to form a hollow fiber membrane module.

[0041] (2) Preparation of metal-organic framework precursor solution: dissolve 2-methylimidazole (21g, 250mmol) and Zn(NO 3 ) 2 ·6H 2 O (37g, 125mmol) is dissolved in the deionized water of 1000ml respectively, and the polyethylene glycol of 10g is added in the 2-methylimidazole solution, obtains the 2-methylimidazole solution containing polyethylene glycol and Zn(NO 3 ) 2 solution.

[0042] (3) Preparation of membrane: the heater outside the hollow fiber membrane module 5 is preset at 30°C, and the 2-methylimidazole solution containin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com