Polymer-embedded metal-organic framework membrane, its preparation method, device and application

A metal-organic framework and polymer technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of poor gas separation effect, low raw material utilization rate, and low selectivity, and achieve energy reduction , Improve utilization efficiency, simplify the effect of synthesis and modification steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation of embodiment 1 metal organic framework ZIF-8 film

[0035] (1) Cut out a polyvinylidene fluoride hollow fiber membrane with a length of 6 cm, place it in a 30 wt % aqueous solution of ethylenediamine, seal it under the condition of 100 ° C for 12 h, take out the membrane after natural cooling, and use After washing with ion water for three times and drying, it is packaged in a cross-flow membrane module to form a hollow fiber membrane module.

[0036] (2) Preparation of metal-organic framework precursor solution: 2-methylimidazole (0.21g, 2.5mmol) and Zn(NO 3 ) 2 ·6H 2 O (0.37g, 1.25mmol) was dissolved in 1000ml deionized water respectively to obtain 2-methylimidazole solution and Zn(NO 3 ) 2 solution.

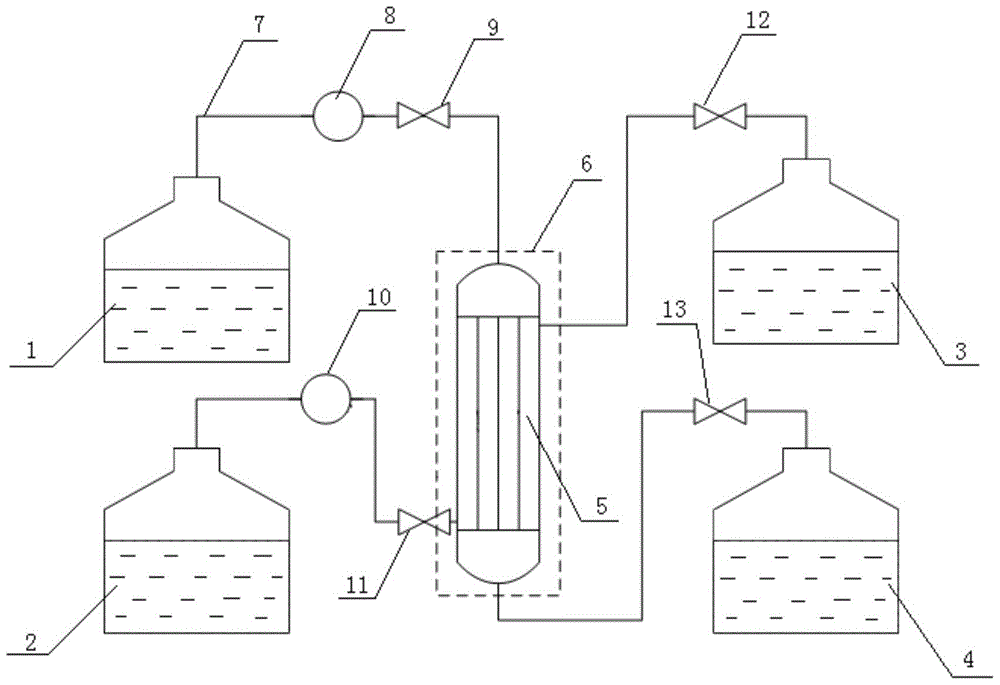

[0037] (3) Preparation of membrane: the heater outside the hollow fiber membrane module 5 is preset at 30°C, and the 2-methylimidazole solution obtained in step (2) and Zn(NO 3 ) 2 The solution is respectively placed in the first feed tank 1 and ...

Embodiment 2

[0039] Example 2 Preparation of metal-organic framework ZIF-8 film embedded in polyvinyl alcohol

[0040] (1) Cut a 6cm-long polyvinylidene fluoride hollow fiber membrane, place it in a 30wt% aqueous solution of ethylenediamine, seal it at 100°C for 12h, take out the membrane after natural cooling, and wash it with water After three times of drying, it is packaged in a cross-flow membrane module to form a hollow fiber membrane module.

[0041] (2) Preparation of metal-organic framework precursor solution: 2-methylimidazole (0.21g, 2.5mmol) and Zn(NO 3 ) 2 ·6H 2 O (0.37g, 1.25mmol) was dissolved in 1000ml of deionized water respectively, and 0.5g polyvinyl alcohol was added in the 2-methylimidazole solution to obtain a 2-methylimidazole solution containing polyvinyl alcohol and Zn(NO 3 ) 2 solution.

[0042] (3) Preparation of membrane: the heater outside the hollow fiber membrane module 5 is preset at 60°C, and the 2-methylimidazole solution containing polyvinyl alcohol o...

Embodiment 3

[0044] Example 3 Preparation of metal-organic framework ZIF-8 film embedded with polyethylene glycol

[0045] (1) Cut a 6cm-long polyvinylidene fluoride hollow fiber membrane, place it in a 30wt% aqueous solution of ethylenediamine, seal it at 100°C for 12h, take out the membrane after natural cooling, and wash it with water After three times of drying, it is packaged in a cross-flow membrane module to form a hollow fiber membrane module.

[0046] (2) Preparation of metal-organic framework precursor solution: dissolve 2-methylimidazole (21g, 250mmol) and Zn(NO 3 ) 2 ·6H 2 O (37g, 125mmol) is dissolved in the deionized water of 1000ml respectively, and the polyethylene glycol of 10g is added in the 2-methylimidazole solution, obtains the 2-methylimidazole solution containing polyethylene glycol and Zn(NO 3 ) 2 solution.

[0047] (3) Preparation of membrane: the heater outside the hollow fiber membrane module 5 is preset at 30°C, and the 2-methylimidazole solution containin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com