Preparation and application of a heavy metal chromium contaminated soil remediation material

A technology for chromium-contaminated soil and heavy metals, applied in the restoration of contaminated soil, soil conditioning materials, carbon preparation/purification, etc., can solve the problem of poor material flow performance and stability, unfavorable soil reuse plant regrowth, and reduction of material For problems such as chromium repair effect, achieve the effect of good stability and fluidity, easy promotion and use, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] A preparation method of biochar particles, the steps are:

[0038] 1) Wash, dry and crush the agricultural waste to obtain substance A;

[0039] 2) Substance A is deoxidized and carbonized under a protective atmosphere, and the carbonized product is ground and sieved to obtain biochar particles.

[0040] Preferably, the agricultural waste is bagasse.

[0041] Preferably, step 2) is specifically: put substance A into a crucible, place it in a muffle furnace with a protective atmosphere, and raise the temperature of the muffle furnace to 500-700°C at a heating rate of 15-25°C / min to reach the temperature After the interval, keep at this temperature for 1-3 hours to fully deoxidize and carbonize, then cool down to room temperature in the muffle furnace, take out the black residue, grind and sieve to obtain biochar particles;

[0042] More preferably, the number of meshes used for the above-mentioned sieving is 24 mesh to 200 mesh, more preferably, 60 mesh to 120 mesh;

...

Embodiment 1

[0061] Preparation of biochar particles with different particle sizes:

[0062] 1) Wash the bagasse, air-dry it, and cut it into sugarcane pieces of 1cm×1cm×1cm;

[0063] 2) Put the treated sugarcane block into the crucible, then put it in the muffle furnace, under the protection of nitrogen, deoxidize carbonization at the set temperature of 600°C, and continue to Carbonize for 2 hours. After the temperature of the muffle furnace drops to room temperature, take out the black residue, grind it, and sieve it (the mesh size of the sieve is 24 mesh to 200 mesh) to obtain biochar particles with different particle sizes (the particle size is 0.701mm~ 0.074 mm), the biochar particles with better stability were selected through sedimentation experiments.

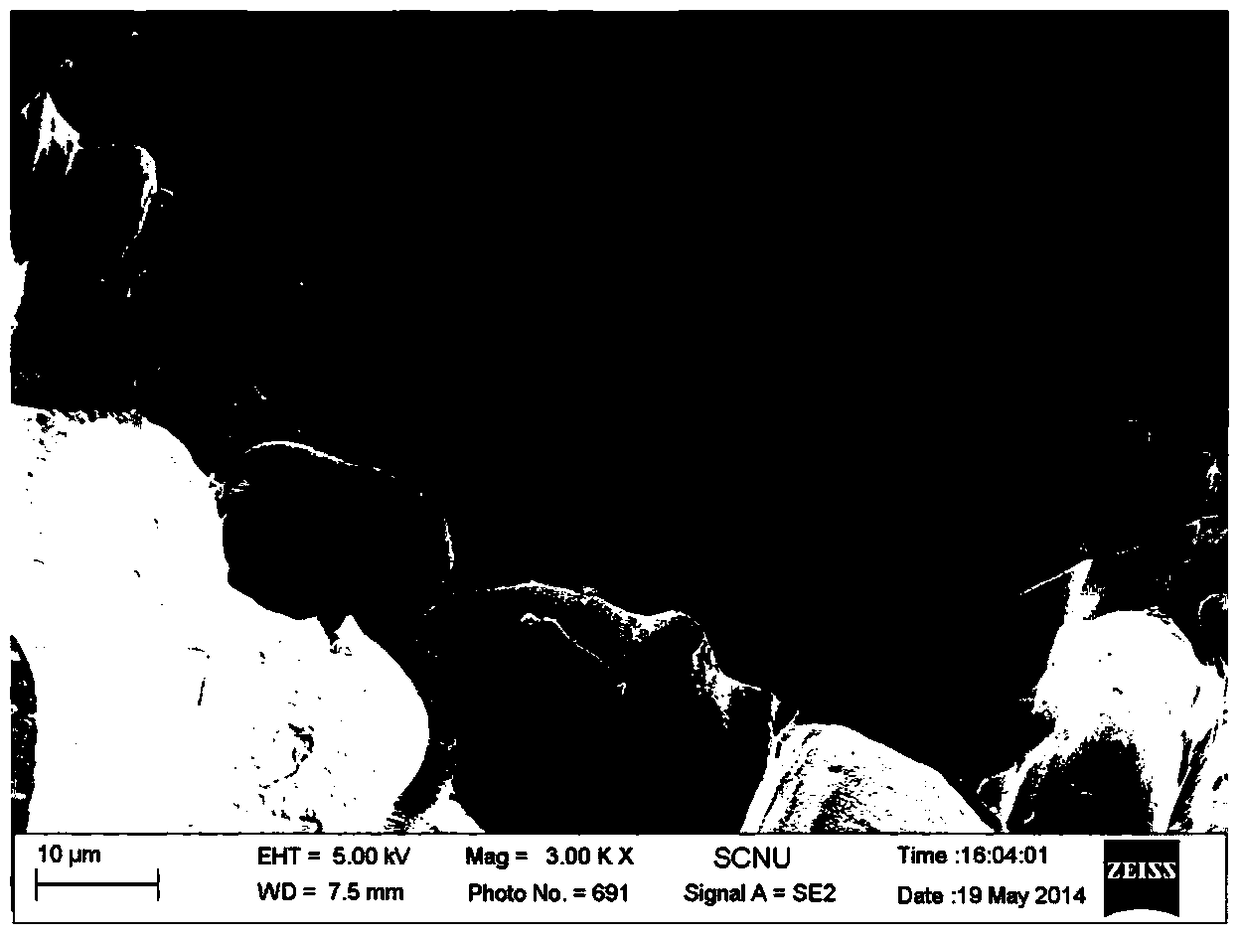

[0064] figure 1 It is a scanning electron microscope (SEM) picture of the biochar particles prepared in this example;

Embodiment 2

[0066] Preparation of supported nanometer zero-valent iron particles in different proportions:

[0067] 1) Prepare 100ml of 0.1mol / L FeSO with ethanol and water (V:V=3:7) 4 ·7H 2 O solution, stirred at a speed of 400rpm for 10min to dissolve and mix to obtain solution A;

[0068] 2) Add biochar particles with better stability (Example 1) into solution A, stir at a speed of 500rpm for 60min, dissolve and mix well, and obtain solution B;

[0069] 3) Prepare 50ml of 0.3mol / L sodium borohydride solution with ethanol and water (V:V=3:7), quickly add it to solution B under the protection of nitrogen, and continue stirring at a speed of 500rpm React for 30 minutes, then separate nanometer zero valent iron by magnetic separation, wash with deoxygenated water, absolute ethanol and acetone respectively, after each washing twice, vacuum dry at 50°C to 60°C to prepare loaded nanometer zero Valence iron particles.

[0070] 4) According to the above method, prepare biochar-nano-zero-val...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com