A kind of preparation method of ultra-high temperature ceramic modified c/c composite material

A technology for ultra-high-temperature ceramics and composite materials, which is applied in the field of preparation of ultra-high-temperature ceramics modified C/C composite materials, and can solve problems such as the decline in mechanical properties of composite materials, long production cycles of process methods, and long preparation cycles of composite materials. Favorable anti-ablation performance, shortened preparation cycle, significant economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

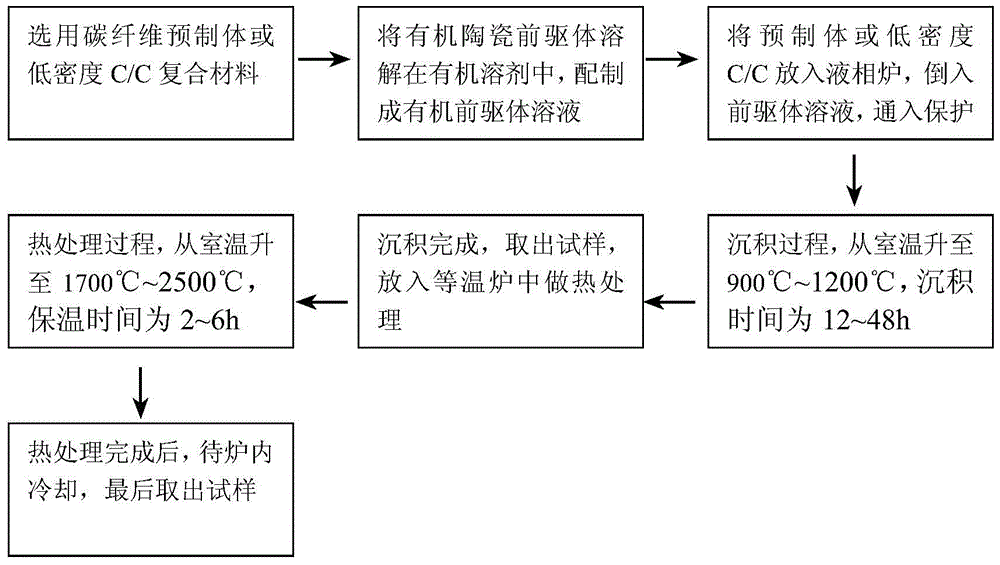

Method used

Image

Examples

Embodiment 1

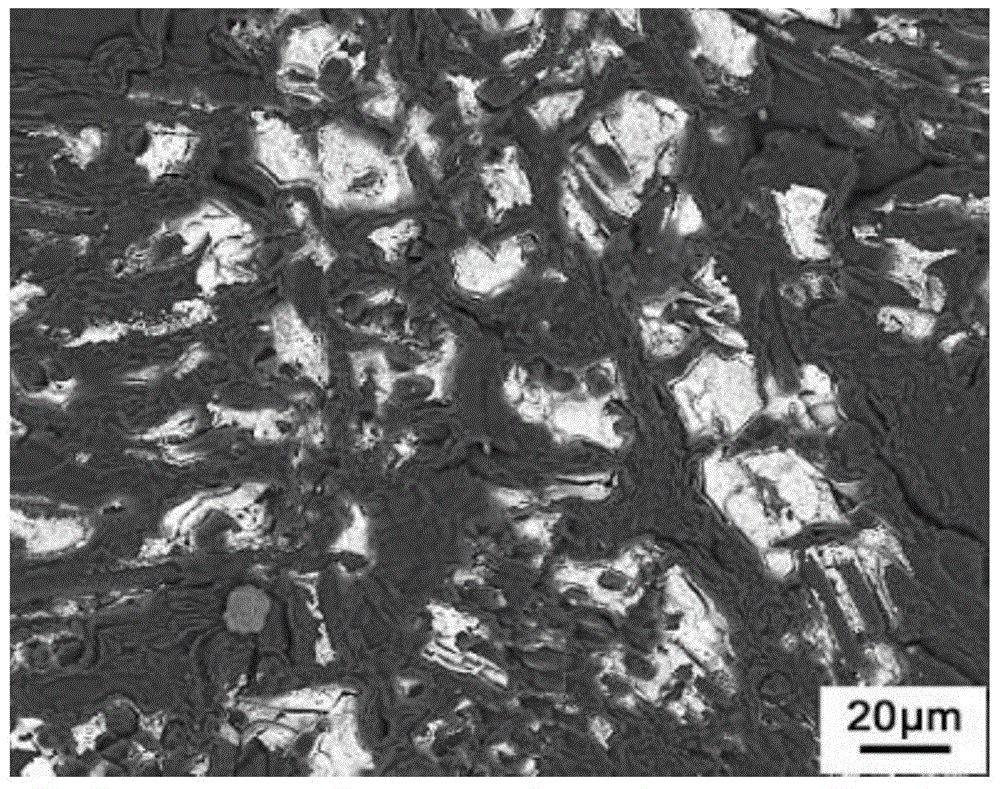

[0027] Step 1: Set the density to 0.45g / cm 3 The 2D carbon felt was processed into a disk with a size of Φ80mm×10mm, ultrasonically cleaned twice in absolute ethanol solution, each time for 15min, and dried at 80°C;

[0028] Weigh 500g of organozirconium precursor and 12L of xylene liquid, dissolve the organozirconium precursor in xylene, and prepare the precursor solution;

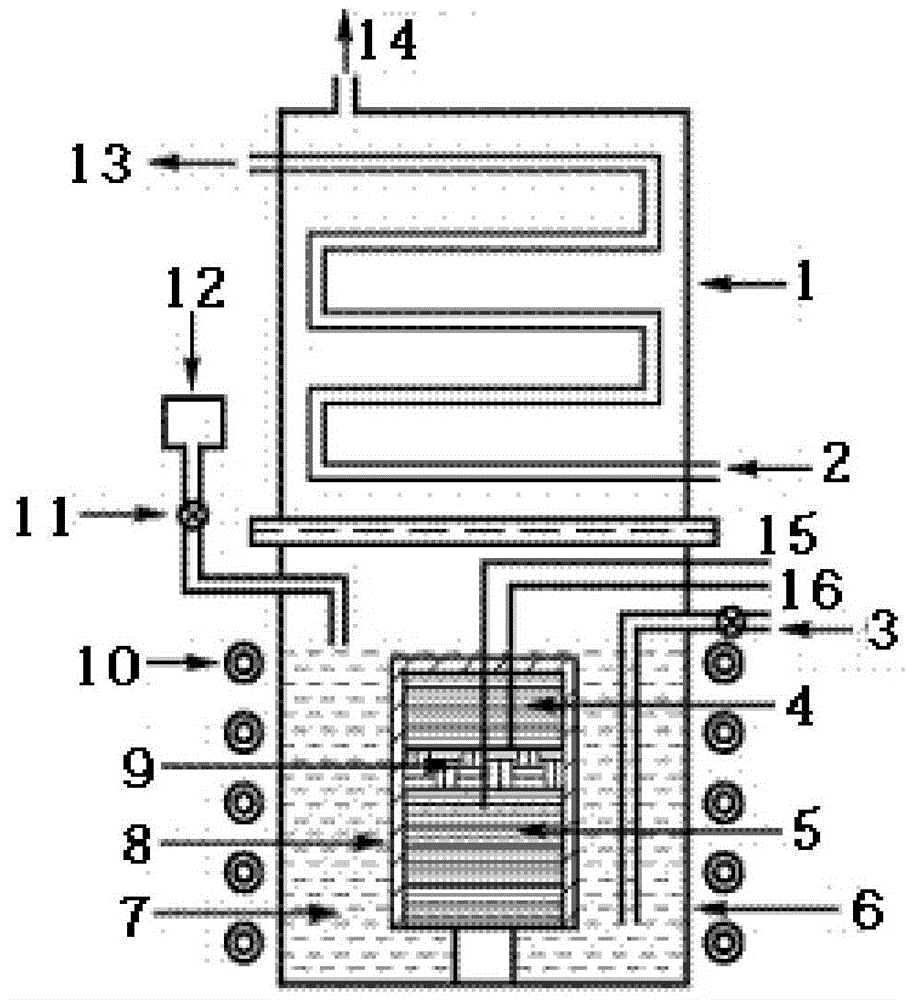

[0029] Step 2: Using chemical liquid-phase vaporization deposition technology, place the processed 2D carbon felt in a liquid-phase deposition furnace, pour the prepared precursor solution into the furnace, and then heat up at a rate of 20°C / min Raise from room temperature to 1200°C, keep warm for 16 hours, then gradually drop the temperature from 1200°C to 600°C at a rate of 20°C / min, turn off the power, cool naturally, and finally take out the 2D carbon felt;

[0030] Step 3: Place the 2D carbon felt deposited in step 2 in an isothermal furnace for heat treatment: raise the temperature from room temper...

Embodiment 2

[0033] Step 1: Set the density to 0.5g / cm 3 The 2D carbon felt is processed into a disc with a size of Φ80mm×15mm, ultrasonically cleaned twice in absolute ethanol solution, each time for 15min, and dried at 80°C; weigh 1kg organic hafnium precursor and measure 10L xylene liquid , and dissolve the organic zirconium precursor in xylene to prepare the precursor solution;

[0034] Step 2: Using chemical liquid-phase vaporization deposition technology, place the processed 2D carbon felt in a liquid-phase deposition furnace, pour the prepared precursor solution into the furnace, and then heat up at a rate of 20°C / min Raise from room temperature to 1000°C, keep warm for 24 hours, then gradually drop the temperature from 1000°C to 600°C at a rate of 20°C / min, turn off the power, cool naturally, and finally take out the 2D carbon felt;

[0035] Step 3: Place the 2D carbon felt treated in step 2 in an isothermal furnace for heat treatment: raise the temperature from room temperature t...

Embodiment 3

[0038] Step 1: Set the density to 0.6g / cm 3The 2D carbon felt is processed into a disc with a size of Φ80mm×20mm, ultrasonically cleaned twice in absolute ethanol solution, each time for 15min, and dried at 80°C; weigh 2kg of organic tantalum precursor and measure 10L of xylene liquid , and dissolve the organic tantalum precursor in xylene to prepare the precursor solution;

[0039] Step 2: Using chemical liquid-phase vaporization deposition technology, place the processed 2D carbon felt in a liquid-phase deposition furnace, pour the prepared precursor solution into the furnace, and then heat up at a rate of 20°C / min Raise from room temperature to 1100°C, keep warm for 36 hours, then gradually drop the temperature from 1100°C to 600°C at a rate of 20°C / min, turn off the power, cool naturally, and finally take out the sample;

[0040] Step 3: Place the sample in step 2 in an isothermal furnace for heat treatment: raise the temperature from room temperature to 2400 °C at a rate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com