Method for preparing coating containing Ti (C and N) with melamine as carbon and nitrogen precursor

A melamine and carbon-nitrogen precursor technology, applied in the coating, metal material coating process, etc., can solve the problems of coating performance degradation, coating component burning, matrix material melting, etc., to meet the design requirements and low cost , the effect of structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] (1) Graphite phase g-C 3 N 4 preparation of

[0033] Put pure melamine into a stainless steel autoclave, seal the lid of the autoclave with graphite, and put it into a muffle furnace for calcination. After 4 hours, stop heating and cool to room temperature with the furnace. After opening the autoclave, a light yellow crude product is obtained. The yellow product is washed with distilled water, dilute hydrochloric acid, and distilled water in sequence, and suction-filtered. The yellow filter cake is placed in a vacuum drying oven to dry in vacuum to obtain a yellow powder sample. The chemical reaction formula is:

[0034]

[0035] (2) Substrate pretreatment

[0036] Remove impurities such as rust, oil stains and oxide layers on the surface of the base metal until metallic luster appears, sandblasting and roughening, then use 99.5% acetone to clean the surface, and dry it with high-pressure air for later use.

[0037] (3) Pre-coating and drying

[0038] With the gr...

Embodiment 1

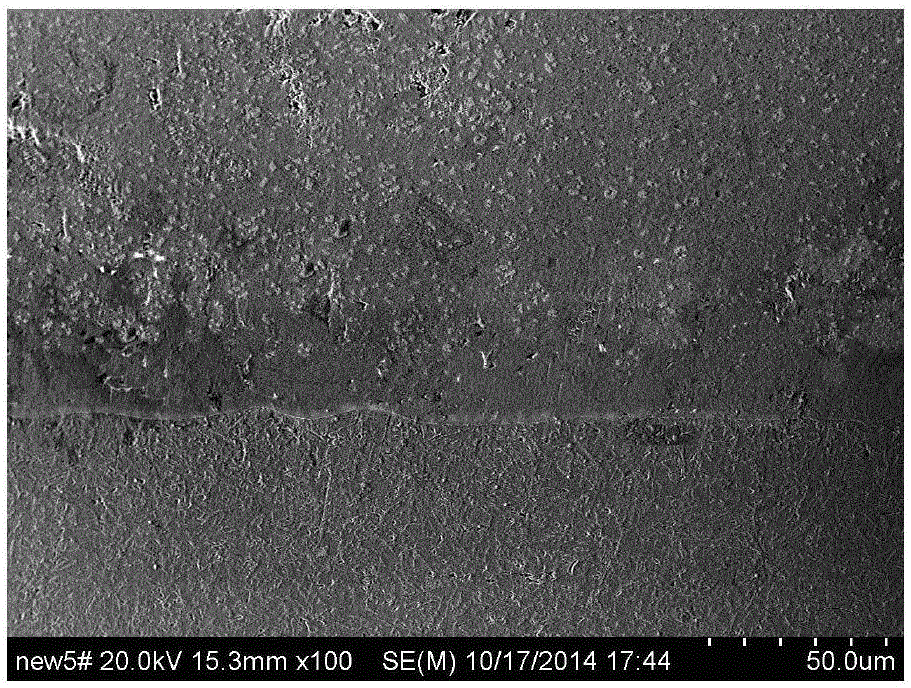

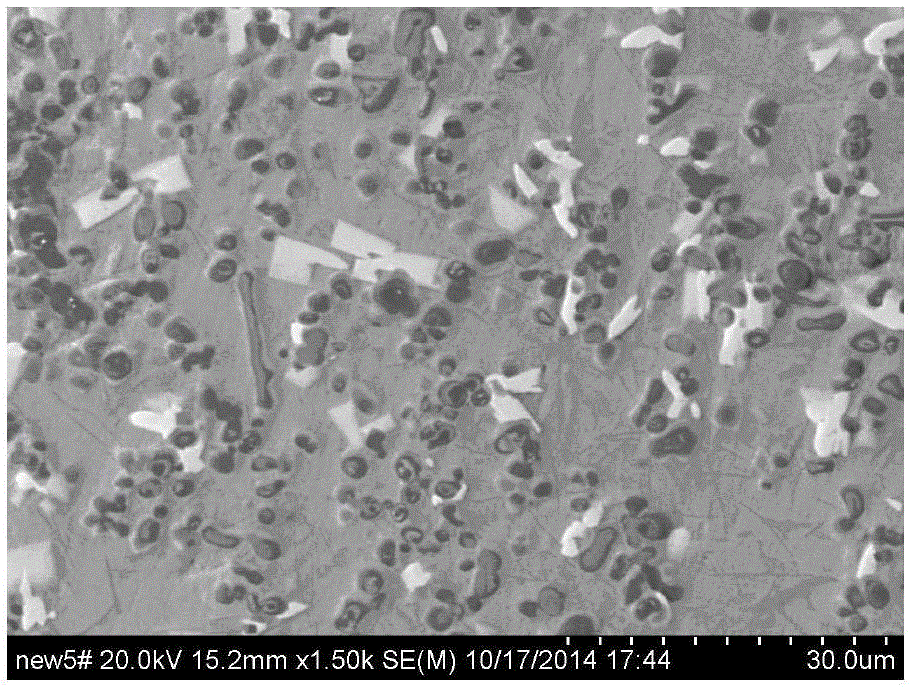

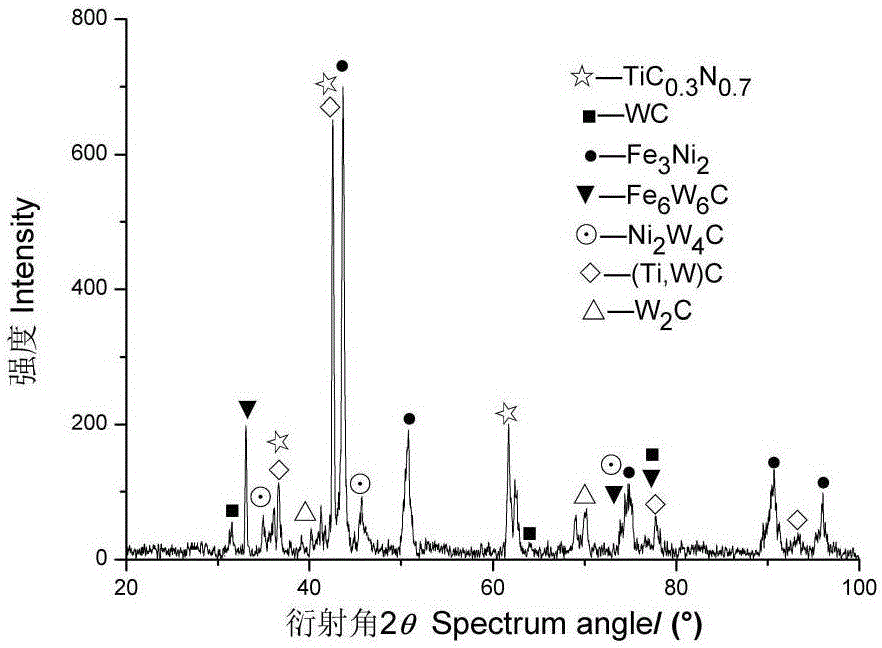

[0052] In this embodiment, the optimized process parameters are used to prepare Ti(C,N)-enhanced iron-nickel-based composite coatings on the surface of Q235 of 50mm×30mm×10mm. The specific implementation methods are as follows:

[0053] (1) Graphite phase g-C 3 N 4 preparation of

[0054] Put pure melamine into a stainless steel autoclave, seal the lid of the autoclave with graphite, put the autoclave into a muffle furnace and heat it to 550 °C at a heating rate of 3-5 °C / min, maintain 550 °C for 4 hours Afterwards, stop heating and cool down to room temperature with the furnace. After opening the kettle, a light yellow crude product is obtained. Take out the light yellow product and wash with distilled water, dilute hydrochloric acid and distilled water, and filter it with suction. Put the yellow filter cake in a vacuum drying oven for 80- Vacuum drying at 100°C for 6 hours to obtain a yellow powder sample, which is the graphite phase g-C 3 N 4 .

[0055] (2) Substrate p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com