A kind of highly wear-resistant S-shaped artificial turf and its preparation method

An artificial turf, high wear-resistant technology, applied in the manufacture of rayon, conjugated synthetic polymer artificial filament, textiles and papermaking, etc., can solve the problem of air quality damage, achieve grass silk protection, excellent performance, and reduce injuries The effect of the probability of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

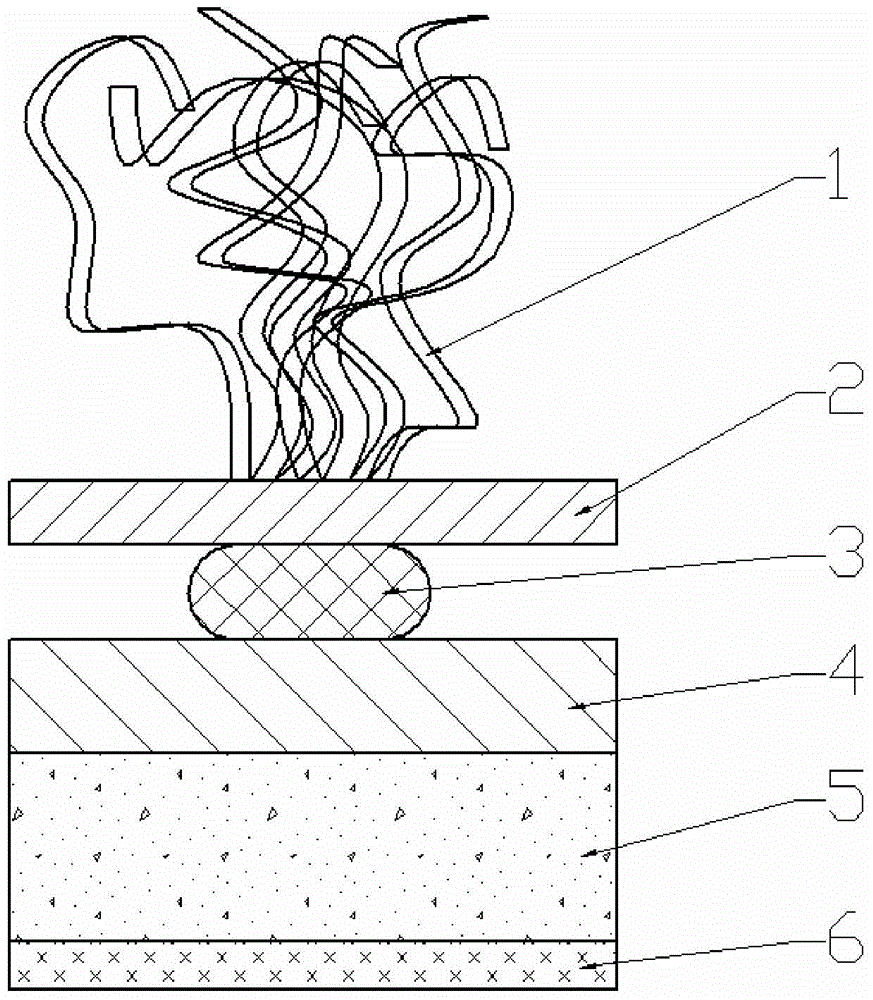

[0038] This embodiment provides a highly wear-resistant S-shaped artificial turf, the structure of which is as follows: figure 1 As shown, it includes S-shaped grass 1 and the base layer with S-shaped grass 1 inserted. The base layer includes a rubber layer 2, and a PVC cushion 4 is provided under the rubber layer 2. There is a gap between them, the lower surface of the PVC cushion layer 4 is connected to the quartz sand particle layer 5, the non-woven fabric layer 6 is adhered below the quartz sand particle layer 5, and the S-shaped grass silk 1 is located between the rubber layer 2 and the PVC cushion layer 4. The inserting section at the middle position, the annular elastic ring 3 is sleeved outside the inserting section, the thickness of the elastic ring 3 is the same as the gap between the rubber layer 2 and the PVC cushion 4.

[0039] The aforementioned elastic ring 3 is a PVA sponge ring; the diameter of the quartz sand particles in the quartz sand particle layer 5 is 0...

Embodiment 2

[0042] This embodiment provides a method for preparing the rubber layer 2 of a highly wear-resistant S-shaped artificial turf, including the following specific steps:

[0043] (1) Weigh the raw materials according to the proportion, the raw materials include: waste tires: 44 parts, tackifying resin 26 parts, softener: 12 parts, activator: 7 parts, adhesive: 5 parts, antioxidant: 2 parts, rubber powder 15 parts, anti-ultraviolet agent: 4 parts, defoamer: 4 parts, propylene-ethylene copolymer: 1.1 parts, unsaturated polyester: 4 parts, after pulverizing the above raw materials, pour them into a mixer and stir evenly, and the temperature is controlled during stirring at 36°C;

[0044] (2) Add the above-mentioned sizing material after stirring in the internal mixer, set the roller distance to 4.5 mm, mix for 3 minutes, set the roller distance to 5.2 mm, and mix for 5 minutes;

[0045] (3) Adjust the roller distance of the internal mixer to 1.3mm, thinly pass the rubber material 5 t...

Embodiment 3

[0049] This embodiment provides a method for preparing a highly wear-resistant S-shaped artificial turf, comprising the following steps:

[0050] (a) Send acrylic resin, polyester acrylate, antioxidant, colorant, composite dispersant, aluminum dioxide nanocomposite particles, and anion powder to the agitator at a stirring speed of 212r / min, and stir and mix evenly to form a mixture ;

[0051] (b) Put the mixture into the extruder for extrusion and drawing. The temperature of each section of the extruder is 90°C, 120°C, 160°C, 200°C, and 220°C; Prepare artificial turf;

[0052] Wherein, the temperature of the heat stretching box is 109°C, and the temperature of the heat treatment box is 101°C;

[0053] (c) Twisting the prepared artificial turf into strands, using a tufting machine to pass the turf through the rubber layer and the elastic ring and tufting it to the PVC cushion to form a semi-finished lawn according to the specified line spacing and stitch distance;

[0054] (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com