Preparation method for polymer/hollow sulfur composite electrode material

A technology of composite electrodes and metal composite materials, which is applied in the field of preparation of polymer/hollow sulfur composite electrode materials, can solve the problems of poor flexibility of metal particles, poor conductivity, and limited effect of sulfur cathode, and achieve simple process, convenient operation, effective Conducive to the effect of industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

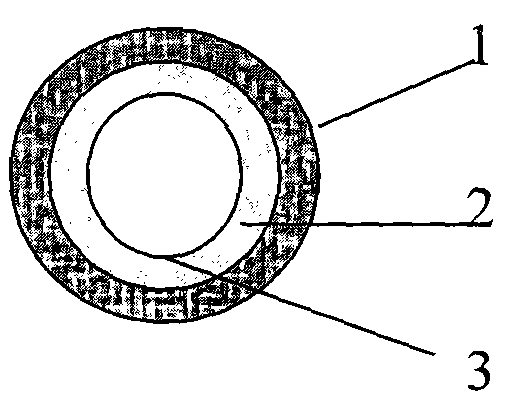

Image

Examples

Embodiment 1

[0026] The composition of a polymer / hollow sulfur composite electrode material is designed as:

[0027] Copper, 15wt%; Sulfur element, mass fraction 80%; Polyaniline, mass fraction 5wt%;

[0028] A preparation method of a polymer / hollow sulfur composite electrode material: comprising the following steps:

[0029] 1) Weigh a certain amount of MCM-41 and copper acetate mixed with alcohol, stir well:

[0030] 2) The product of step 1 was stirred, heated to evaporate, dried, sintered at a high temperature at 500°C for 5 hours in an air atmosphere, and then reduced for 2 hours in a mixed atmosphere of argon and hydrogen at 400°C to obtain an MCM-41 / copper composite material;

[0031] 3) Mix the MCM-41 / copper composite material and elemental sulfur in a certain proportion, press into tablets, place in a closed container, heat to 400°C, and condense slowly to obtain the sulfur / MCM-41 / copper composite material;

[0032] 4) Weigh a certain mass of sulfur / MCM-41 / copper composite mixed...

Embodiment 2

[0036] The composition of a polymer / hollow sulfur composite electrode material is designed as:

[0037] Silver, 15wt%; Sulfur element, mass fraction 77%; Polypyrrole, mass fraction 8wt%;

[0038] A preparation method of a polymer / hollow sulfur composite electrode material: comprising the following steps:

[0039] 1) Weigh a certain mass of KIT-1 and silver acetate and mix it in acetone, stir well:

[0040] 2) The product of step 1 was stirred, heated to evaporate, dried, sintered at a high temperature of 700°C in an air atmosphere for 1 hour, and then reduced in an atmosphere of argon and hydrogen at 300°C for 4 hours to obtain a KIT-1 / silver composite material;

[0041] 3) Mix the KIT-1 / silver composite material and elemental sulfur in a certain proportion, press into tablets, place in a closed container, heat to 450°C, and slowly condense to obtain the sulfur / KIT-1 / silver composite material;

[0042] 4) Weigh a certain mass of sulfur / KIT-1 / silver composite mixed with alcoh...

Embodiment 3

[0046] The composition of a polymer / hollow sulfur composite electrode material is designed as:

[0047] Nickel, 10wt%; sulfur element, 80% by mass; polyacetylene, 10wt% by mass;

[0048] A preparation method of a polymer / hollow sulfur composite electrode material: comprising the following steps:

[0049] 1) Weigh a certain mass of SBA-15 and nickel acetate and mix it with ether, stir well:

[0050] 2) The product of step 1 was stirred, heated to evaporate, dried, sintered at 600°C in an air atmosphere for 2 hours at a high temperature, and then reduced in an atmosphere of argon and hydrogen at 500°C for 1 hour to obtain a SBA-15 / nickel composite material;

[0051] 3) Mix SBA-15 / nickel composite material and elemental sulfur in a certain proportion, press into tablets, place in a closed container, heat to 480°C, and slowly condense to obtain sulfur / SBA-15 / nickel composite material;

[0052] 4) Weigh a certain mass of sulfur / SBA-15 / nickel composite mixed alcohol aqueous solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com