CsPMo/g-C3N4-Bi2O3 photocatalyst and preparation method therefor and application thereof in phenolic wastewater treatment

A photocatalyst, g-c3n4 technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, light water/sewage treatment, etc., can solve the problem of low utilization efficiency of visible light, to facilitate oxidation, reduce treatment costs, The effect of improving the processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Embodiment 1 catalyst preparation method

[0057] (1) CsPMo(1:3) / g-C 3 N 4 -Bi 2 o 3 The preparation of photocatalyst, the steps are as follows:

[0058] (1) Add 100mg of g-C 3 N 4 Dissolve in 60mL of water, stir for 10min, ultrasonically disperse for 40min, centrifuge at 4000r / min, take 50mL of the upper emulsion, add 1g of Bi 2 o 3 .

[0059] (2) Ultrasonic disperse again for 40 minutes, add 100 mg of phosphomolybdic acid, stir for 10 minutes, wait until it is completely dissolved, add 0.0536 g of cesium carbonate, and react for 60 minutes.

[0060] (3) Rotate the yellow precipitate to dryness and grind it to get CsPMo / g-C 3 N 4 -Bi 2 o 3 .

[0061] Where: g-C 3 N 4 with Bi 2 o 3 The mass ratio is about 1:10, and the molar ratio of phosphomolybdic acid to cesium carbonate is 1:3.

[0062] (2) CsPMo(1:3) / Bi 2 o 3 The preparation of photocatalyst, the steps are as follows:

[0063] (1) Add 1g of Bi to 50mL of water 2 o 3 , stirred for 40min.

[0...

Embodiment 2

[0074] Take 0.1g of prepared catalyst Bi 2 o 3 and CsPMo / Bi 2 o 3 , CsPMo / g-C 3 N 4 -Bi 2 o 3 , Dissolve CsPMo in 0.5mL ethylene glycol, ultrasonically disperse for 30min, drop-coat on conductive glass (FTO) (6cm*1cm), drop-coat size is 1cm*1cm, apply twice, 20μL each time, vacuum dry at 80°C , making Bi2 O 3 , CsPMo / Bi 2 O 3 , CsPMo / g-C 3 N 4 -Bi 2 O 3 electrode.

[0075] The CsPMo / g-C 3 N 4 -Bi 2 O 3 Electrodes are placed in Na 2 SO 4 (0.1mol / L), Na 2 SO 3 (0.1mol / L) mixed solution, under the electrochemical workstation 3-electrode system, with CsPMo / g-C 3 N 4 -Bi 2 O 3 The electrode is the working electrode, the platinum sheet is the counter electrode, the silver electrode is the reference electrode, and the xenon lamp is the light source.

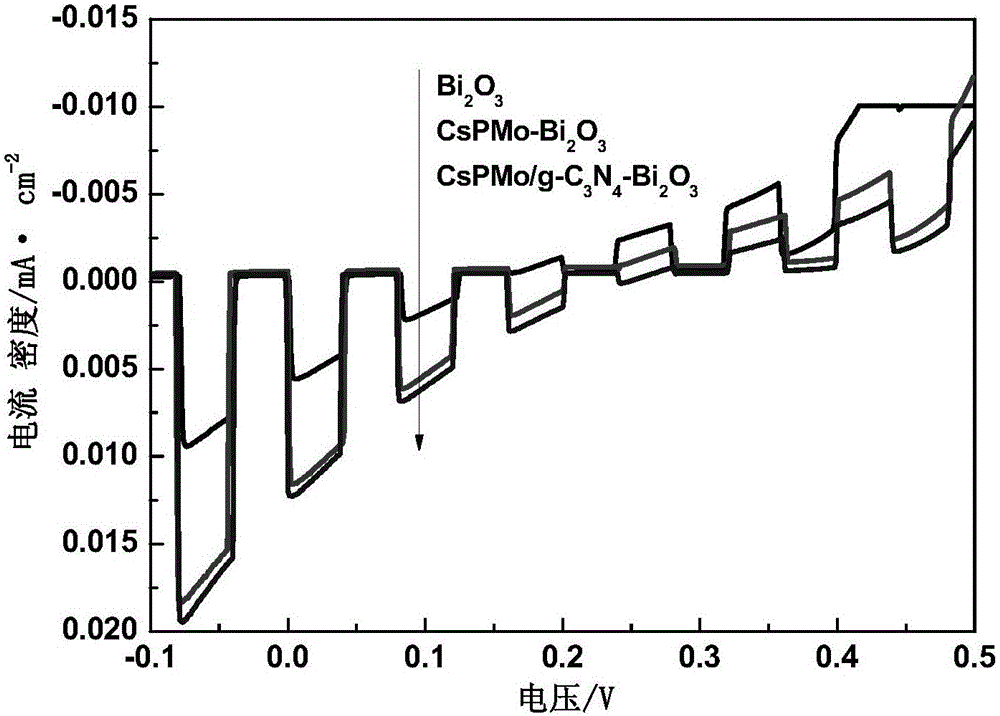

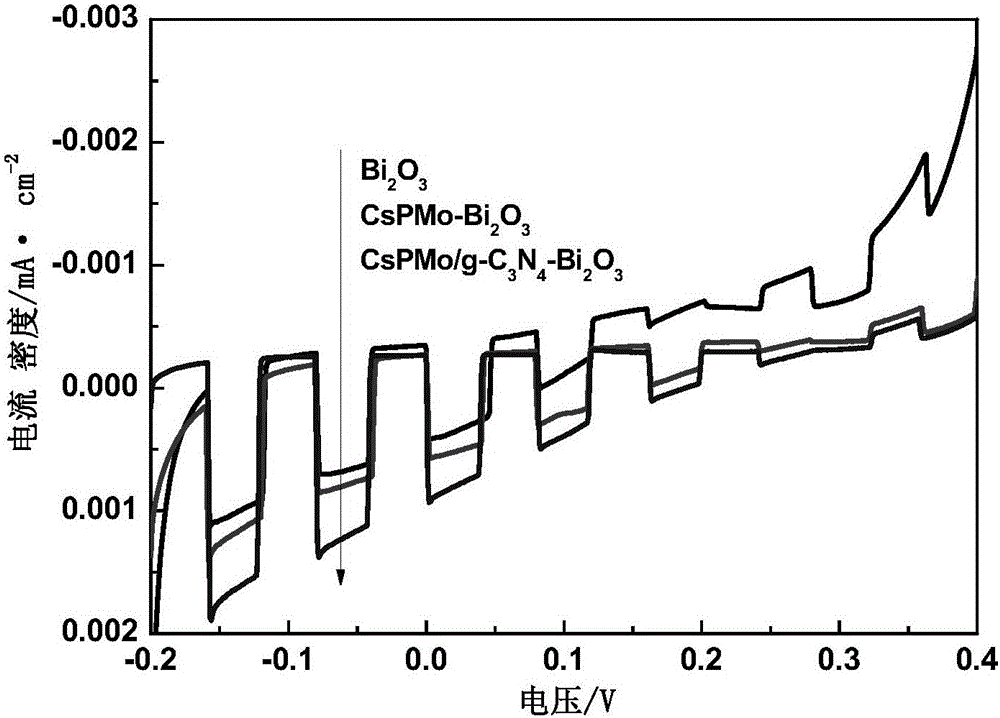

[0076] figure 1 , figure 2 The photocurrent density maps of the three electrodes under UV-visible light and visible light, respectively.

[0077] from figure 1 It can be seen that CsPMo / Bi 2 O 3 , CsPMo / ...

Embodiment 3

[0080] Add phenol-containing wastewater with a volume of 50 mL and a concentration of 10 mg / L to the reactor, and add 50 mg of CsPMo (1:3) / g-C 3 N 4 -Bi 2 O 3 Visible light catalyst, no need to adjust pH, continuous stirring, stirring in a dark place for 30 min until the adsorption equilibrium, turning on the visible light source, and reacting for 5 hours.

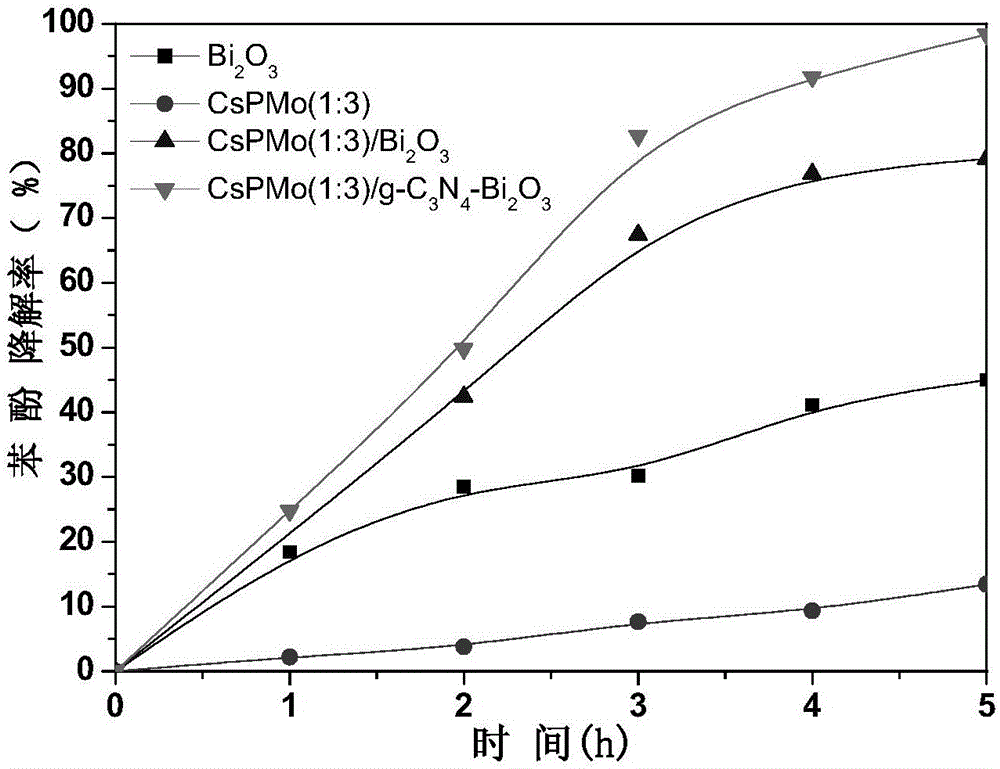

[0081] Change the photocatalyst to the photocatalyst Bi prepared in Example 1 2 O 3 , CsPMo(1:3), CsPMo(1:3) / Bi 2 O 3 , CsPMo(1:3) / g-C 3 N 4 -Bi 2 O 3 Comparing the effect of phenol oxidation, the results are as follows image 3 .

[0082] like image 3 , under the same conditions, the modified CsPMo(1:3) / g-C 3 N 4 -Bi 2 O 3 Ratio CsPMo(1:3) / Bi 2 O 3 , CsPMo(1:3), Bi 2 O 3 The effects of phenol oxidation were improved to varying degrees. After 5 hours, CsPMo(1:3) / g-C 3 N 4 -Bi 2 O 3 The oxidation rate of p-phenol reaches 97%, which is about Bi 2 O 3 2 times.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com