Preparation process of multicolor hollow ceramic plate

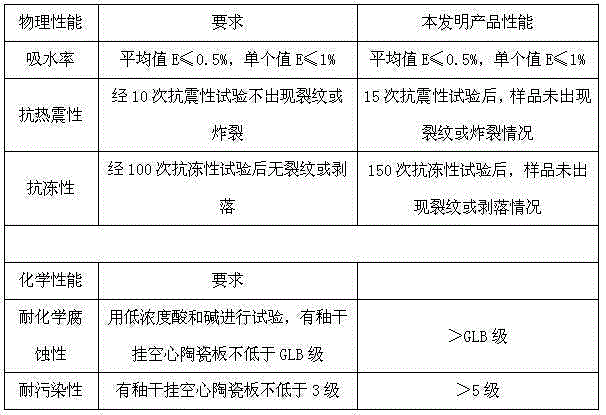

A preparation process, technology of empty ceramic plates, applied in the production of clay products, ceramic materials, and other household appliances, etc., can solve the problems of low thermal shock resistance and low frost resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A preparation process for a multi-color hollow ceramic plate, which is prepared from ingredients 1, 2, and 3 with a weight ratio of 1:2:1; wherein:

[0038] Ingredients 1 is made of the following percentages of raw materials: clay 34%, pyrite tailings 26%, black soil 6%, quartz sand 12%, additives 7%, silicon pyroxene 3%, embryo body enhancer 3%, sapropel 0.3%, Fe 2 o 3 0.5% and extra black 2.3%;

[0039] The second ingredient is made of the following percentages of raw materials: talc 31%, black soil 20%, kaolin 12%, rutile 20%, zirconia 8%, sapropel 0.3%, plasticizer 0.4% and orange 4.9%;

[0040] The third ingredient is made of the following percentages of raw materials: bimodal α-alumina micropowder 28%, activated alumina micropowder 14%, fused silica 28%, lithium feldspar 10%, silicon pyroxene 3%, talc 3%, embryo body Strengthening agent 3%, putrid sodium 0.3%, debonding agent 0.4% and iron red 5.1%.

[0041] In the first ingredient, the raw materials of the ad...

Embodiment 2

[0066] A kind of preparation technology of multi-color hollow ceramic plate as described in embodiment 1, wherein:

[0067] Ingredients 1 is made of the following percentages of raw materials: white clay 32%, pyrite tailings 28%, black soil 5%, quartz sand 14%, additives 7%, silicon pyroxene 3%, embryo body enhancer 3%, sapropine 0.3%, Fe 2 o 3 0.6% and extra black 2.3%;

[0068] The second ingredient is made of the following percentages of raw materials: talc 29%, black soil 18%, kaolin 13%, rutile 22%, zirconia 10%, sapropel 0.3%, plasticizer 0.5% and orange 5.3%;

[0069] The third ingredient is made of the following percentages of raw materials: bimodal α-alumina powder 25%, activated alumina powder 12%, fused silica 26%, lithium feldspar 9%, silica pyroxene 3%, talc 3%, embryo body Strengthening agent 3%, putrid sodium 0.3%, debonding agent 0.4% and iron red 5.6%.

[0070] The preparation process of the described hollow ceramic plate comprises the following steps:

...

Embodiment 3

[0077] A kind of preparation technology of multi-color hollow ceramic plate as described in embodiment 1, wherein:

[0078] Ingredients 1 is made of the following percentages of raw materials: clay 30%, pyrite tailings 30%, black soil 5%, quartz sand 15%, additives 7%, silicon pyroxene 3%, embryo body enhancer 3%, sapropel 0.3%, Fe 2 o 3 0.4% and extra black 2.3%;

[0079] Ingredients 2 is made of the following percentages of raw materials: 32% talc, 15% black soil, 14% kaolin, 20% rutile, 12% zirconia, 0.3% sapropel, 0.4% plasticizer and 5.8% orange;

[0080] The third ingredient is made of the following percentages of raw materials: bimodal α-alumina micropowder 20%, activated alumina micropowder 15%, fused silica 21%, lithium feldspar 13%, silicon pyroxene 3%, talc 3%, embryo body Strengthening agent 3%, putrid sodium 0.3%, debonding agent 0.4% and iron red 4.3%.

[0081] The preparation process of the described hollow ceramic plate comprises the following steps:

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com