A wear-resistant and anti-seepage epoxy protective coating and preparation method thereof

A protective coating, epoxy technology, used in epoxy resin coatings, coatings, anti-corrosion coatings, etc., to increase wear resistance, excellent corrosion resistance, and enhance impermeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of the wear-resistant and anti-seepage epoxy protective coating of the present invention comprises the following steps:

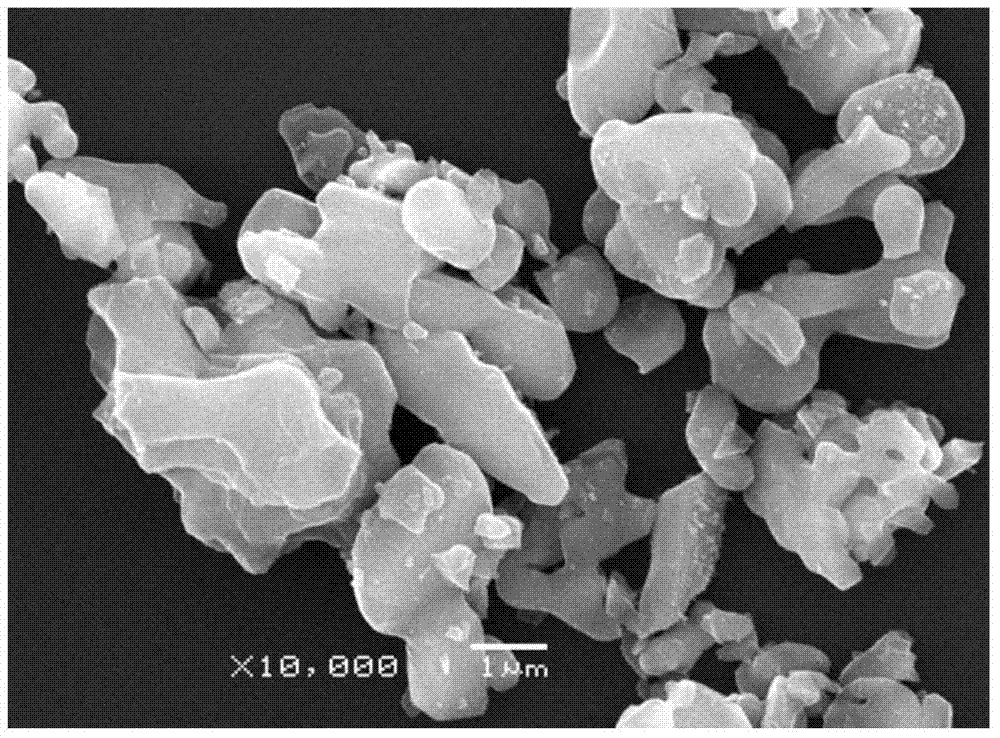

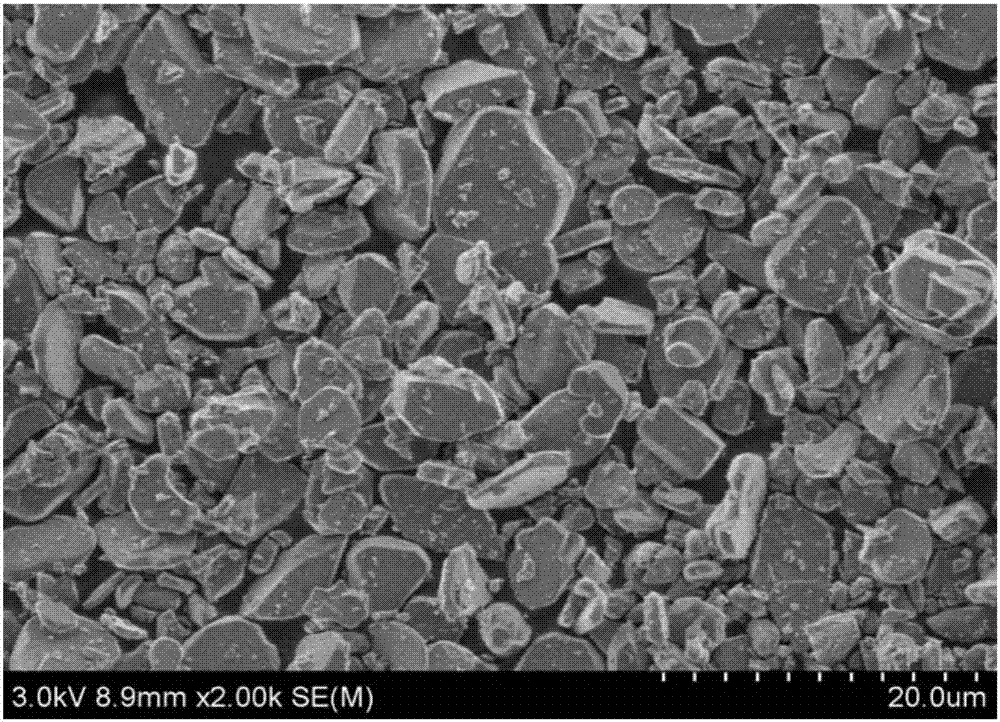

[0032] (1). Preparation of component A: Weigh 1500 mesh alumina powder and 800 mesh alumina powder, dry in an oven after mixing, add diluent, ethanol, dispersant, silane coupling agent, corrosion inhibitor, and then Then heat in the oven, take it out, add epoxy resin, stir evenly, and get A component, set aside;

[0033] (2). Prepare component B: weigh polyamide curing agent, add diluent and ethanol, stir evenly to obtain component B, set aside;

[0034] (3).Heating the configured components A and B in an oven to remove air bubbles;

[0035] (4). Mix and stir components A and B evenly to obtain an alumina epoxy coating;

[0036] (5). Spraying aluminum oxide epoxy paint on the treated substrate surface;

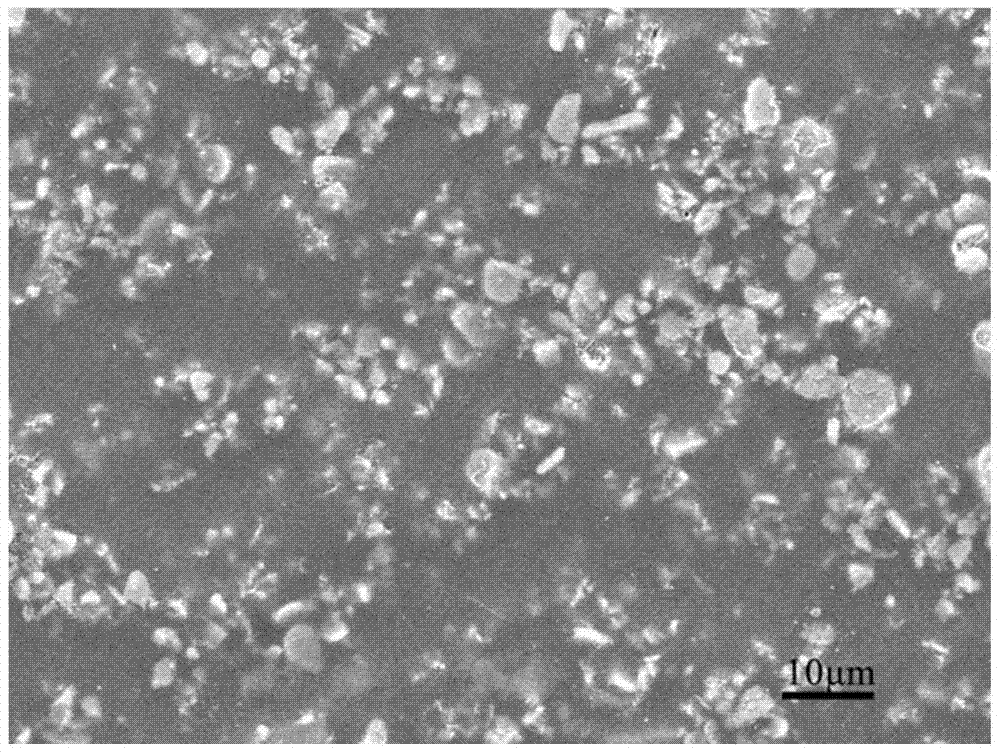

[0037] (6). The sprayed coating film is dried and cured to obtain a wear-resistant and impermeable epoxy protective coatin...

Embodiment 1

[0044] Preparation of component A: Weigh 20 parts of 1500 mesh alumina powder and 15 parts of 800 mesh alumina powder, mix them and put them in an oven at 90°C for 1 hour, then add 12 parts of benzyl alcohol, 20 parts of ethanol, and 2 parts of titanate Coupling agent, 1 part of silane coupling agent KH-560, 2 parts of benzotriazole and stirred for 15 minutes, heated in an oven at 90°C for 1 hour, immediately added 28 parts of bisphenol A epoxy resin E-44 ( 6101) Stir evenly under the condition of ultrasonic vibration to obtain the coating A component, set aside;

[0045] Preparation of component B: Weigh 52 parts of low-molecular-weight 650 polyamide and add 24 parts of benzyl alcohol and 24 parts of ethanol to obtain component B of the coating, which is set aside;

[0046] Remove air bubbles: Heat the prepared components A and B in an oven at 90°C for 3 hours.

[0047] Preparation of alumina epoxy coating: uniformly mix components A and B to obtain an alumina epoxy coating ...

Embodiment 2

[0051] Preparation of component A: Weigh 20 parts of 1500 mesh alumina powder and 18 parts of 800 mesh alumina powder, mix them and put them in an oven at 90°C for 1 hour, then add 10 parts of benzyl alcohol, 18 parts of ethanol, and 1 part of titanate Coupling agent, 2 parts of silane coupling agent KH-560, 2 parts of benzotriazole and stirred for 15 minutes, heated in an oven at 90°C for 1 hour, immediately added 29 parts of bisphenol A epoxy resin E-44 ( 6101) Stir evenly under the condition of ultrasonic vibration to obtain the coating A component, set aside;

[0052]Preparation of component B: Weigh 57 parts of low-molecular-weight polyamide 650 and add 23 parts of benzyl alcohol and 20 parts of ethanol to obtain component B of the coating, which is set aside;

[0053] Remove air bubbles: Heat the prepared components A and B in an oven at 90°C for 3 hours;

[0054] Preparation of alumina epoxy coating: uniformly mix component A and component B of the coating to obtain an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com