Texture surface making method for polycrystalline silicon solar battery

A solar cell and polysilicon technology, applied in chemical instruments and methods, circuits, crystal growth, etc., can solve the problem of low photoelectric conversion rate of polysilicon surface light trapping effect, fast reaction speed of acid on silicon wafer, uneven texture of cell, etc. problems, to achieve the effect of improving texturing effect and uniformity, good consistency, increasing stability and controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

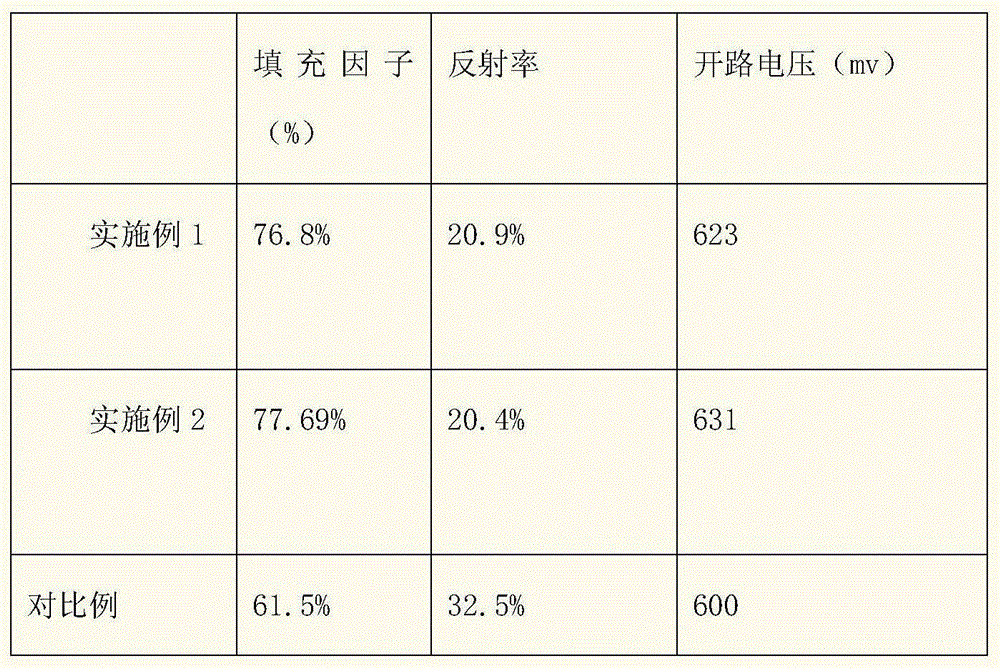

Examples

Embodiment 1

[0021] In order to solve the above-mentioned technical problems, the technical solution adopted in the present invention is: a method for making texture of a polycrystalline silicon solar cell, the steps comprising:

[0022] (1) Firstly, prepare the aqueous solution of velvet in the velvet-making tank, and the preparation raw materials include: 5wt% hydrofluoric acid, 25wt% nitric acid, 0.5wt% silicofluoric acid, 0.1wt% acetic acid, 0.5wt% additive, and the balance is water; Mix the above components and stir evenly;

[0023] The additives are composed of: 0.5% polyvinyl alcohol, 0.2% triethanolamine, 3% hydrolyzed polymaleic anhydride, 0.06% polyvinylpyrrolidone, and the balance is water:

[0024] (2) Maintain the temperature of the texturing aqueous solution in step (1) at 15°C, then place the polysilicon sheet in the aqueous solution for 120s, and simultaneously perform ultrasonic vibration at an ultrasonic frequency of 40KHZ; then take it out and place it in 0.3% sodium hyd...

Embodiment 2

[0027] The other steps are the same as in Example 1, the difference is that: the velvet-making aqueous solution is prepared in the velvet-making tank, and the preparation raw materials include: 10wt% hydrofluoric acid, 45wt% nitric acid, 1.5wt% silicofluoric acid, 0.2wt% acetic acid, additives 1.0 wt%, and the balance is water.

[0028] The additive is composed of: 0.5% of polyvinyl alcohol, 0.7% of triethanolamine, 1.5% of hydrolyzed polymaleic anhydride, 0.07% of polyvinylpyrrolidone, and the balance is water.

[0029] figure 2 As shown, the suede surface prepared in the embodiment of the present invention has uniform, small and relatively uniform suede surface size.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com