A kind of ultraviolet-visible light absorber and application thereof

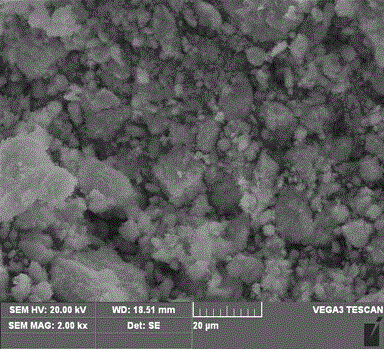

An absorber and visible light technology, applied in the field of ultraviolet light absorbing materials, to achieve the effect of small particle size, good thermal stability and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1 An ultraviolet-visible light absorber is prepared by the following preparation method:

[0032] 1) The preparation concentration is 0.10 mol L -1 Lanthanum oxide solution and sulfuric acid solution with a mass concentration of 70%, add sulfuric acid solution dropwise to the lanthanum oxide solution, react at 40°C for 2 h to generate La 2 (SO 4 ) 3 ; Wherein, the volume ratio of the lanthanum oxide solution and the sulfuric acid solution is 2:3;

[0033] 2) The preparation concentration is 0.30 mol L -1 Tungstic acid solution, and add ammoniacal liquor to tungstic acid solution, reaction prepares ammonium tungstate; Wherein, the volume ratio of described tungstic acid solution and ammoniacal liquor is 1:3;

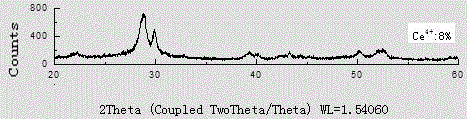

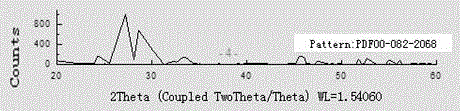

[0034] 3) To the La generated in step 1) 2 (SO 4 ) 3 Add the ammonium tungstate solution generated in step 2) dropwise into the solution until a white precipitate is formed, then add Ce(SO 4 ) 2 4H 2 The O solution continued to react for 30 min, a...

Embodiment 2

[0044] Example 2 An ultraviolet-visible light absorber is prepared by the following preparation method:

[0045] 1) The preparation concentration is 0.12 mol L -1 Lanthanum oxide solution and sulfuric acid solution with a mass concentration of 80%, add sulfuric acid solution dropwise to the lanthanum oxide solution, react at 50°C for 2.5h to generate La 2 (SO 4 ) 3 ; Wherein, the volume ratio of the lanthanum oxide solution and the sulfuric acid solution is 5:8;

[0046] 2) The preparation concentration is 0.40 mol L -1 Tungstic acid solution, and add ammoniacal liquor to tungstic acid solution, reaction prepares ammonium tungstate; Wherein, the volume ratio of described tungstic acid solution and ammoniacal liquor is 2:7;

[0047] 3) To the La generated in step 1) 2 (SO 4 ) 3 Add the ammonium tungstate solution generated in step 2) dropwise into the solution until a white precipitate is formed, then add Ce(SO 4 ) 2 4H 2 The O solution continued to react for 45 min, ...

Embodiment 3

[0052] Example 3 An ultraviolet-visible light absorber is prepared by the following preparation method:

[0053] 1) The preparation concentration is 0.15 mol L -1 Lanthanum oxide solution and sulfuric acid solution with a mass concentration of 85%, add sulfuric acid solution dropwise to the lanthanum oxide solution, react at 60°C for 3 h to generate La 2 (SO 4 ) 3 ; Wherein, the volume ratio of the lanthanum oxide solution and the sulfuric acid solution is 3:5;

[0054] 2) The preparation concentration is 0.50 mol L -1 Tungstic acid solution, and add ammoniacal liquor to tungstic acid solution, react and prepare ammonium tungstate; Wherein, the volume ratio of described tungstic acid solution and ammoniacal liquor is 1:4;

[0055] 3) To the La generated in step 1) 2 (SO 4 ) 3 Add the ammonium tungstate solution generated in step 2) dropwise into the solution until a white precipitate is formed, then add Ce(SO 4 ) 2 4H 2 The O solution continued to react for 60 min, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com