Preparation method and application of heterojunction photoelectrode

A heterojunction and photoelectrode technology, applied in the direction of material electrochemical variables, can solve problems such as limiting photoelectric conversion efficiency, and achieve the effect of cheap and easy-to-obtain materials, good photoelectrochemical performance, and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

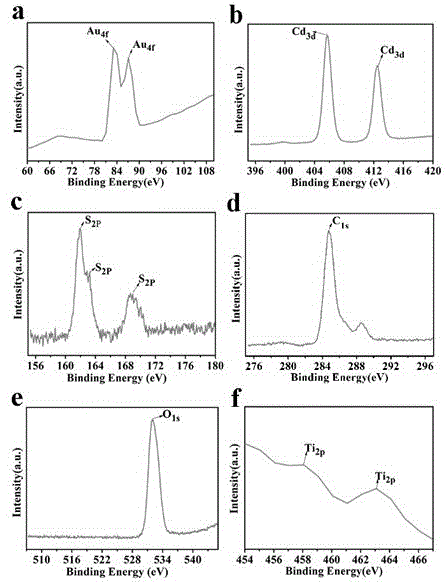

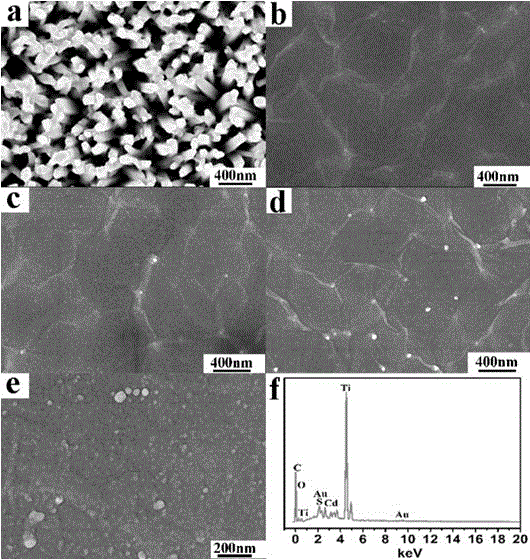

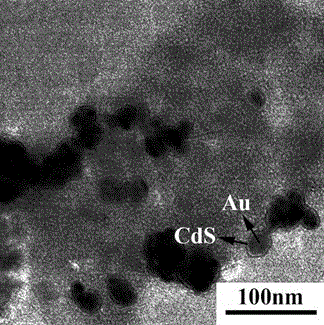

Image

Examples

Embodiment 1

[0035] A. TiO was prepared on FTO substrate 2 nanorod array

[0036] The described preparation of TiO on the FTO substrate 2 The steps of nanorod array are:

[0037] (1) Dissolve 15mL of hydrochloric acid solution in 15mL of deionized water, then slowly add 0.35mL of butyl titanate to the solution and stir until the solution becomes clear to obtain mixed solution A.

[0038] (2) Transfer the mixed solution A to a tetrafluoroethylene-lined reaction kettle, put the cleaned FTO substrate in it, with the conductive side facing down, raise the temperature to 180°C for 6 hours, and cool naturally to obtain surface deposition monolayer TiO 2 FTO substrate of nanorod arrays.

[0039] (3) Add 2 mL of acetic acid to 100 mL of ethanol, and then add 1.5 mL of butyl titanate and stir to form a uniform mixed solution B.

[0040] (4) Take out the above-mentioned FTO substrate, wash it with deionized water, and then soak it in solution B for 1 hour.

[0041] (5) Put the soaked FTO subst...

Embodiment 2

[0047] A. TiO was prepared on FTO substrate 2 Nanorod Arrays:

[0048] The described preparation of TiO on the FTO substrate 2 The steps of nanorod array are:

[0049] (1) Dissolve 15mL of hydrochloric acid solution in 15mL of deionized water, then slowly add 0.35mL of butyl titanate to the solution and stir until the solution becomes clear to obtain mixed solution A.

[0050] (2) Transfer the mixed solution A to a tetrafluoroethylene-lined reaction kettle, put the cleaned FTO substrate in it, with the conductive side facing down, raise the temperature to 180°C for 6 hours, and cool naturally to obtain surface deposition monolayer TiO 2 FTO substrate of nanorod arrays.

[0051] (3) Add 2 mL of acetic acid to 100 mL of ethanol, and then add 1.5 mL of butyl titanate and stir to form a uniform mixed solution B.

[0052] (4) Take out the above-mentioned FTO substrate, wash it with deionized water, and then soak it in solution B for 1 hour.

[0053] (5) Put the soaked FTO sub...

Embodiment 3

[0059] A. TiO was prepared on FTO substrate 2 nanorod arrays.

[0060] The described preparation of TiO on the FTO substrate 2 The steps of nanorod array are:

[0061] (1) Dissolve 15mL of hydrochloric acid solution in 15mL of deionized water, then slowly add 0.35mL of butyl titanate to the solution and stir until the solution becomes clear to obtain mixed solution A.

[0062] (2) Transfer the mixed solution A to a tetrafluoroethylene-lined reaction kettle, put the cleaned FTO substrate in it, with the conductive side facing down, raise the temperature to 180°C for 6 hours, and cool naturally to obtain surface deposition monolayer TiO 2 FTO substrate of nanorod arrays.

[0063] (3) Add 2 mL of acetic acid to 100 mL of ethanol, and then add 1.5 mL of butyl titanate and stir to form a uniform mixed solution B.

[0064] (4) Take out the above-mentioned FTO substrate, wash it with deionized water, and then soak it in solution B for 1 hour.

[0065] (5) Put the soaked FTO sub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com