Preparation method of nanometer nickel protoxide-nickel-silicon alloy lithium ion battery negative electrode material

A lithium-ion battery, nickel-silicon alloy technology, applied in the direction of battery electrodes, nanotechnology, nanotechnology, etc., can solve the problems of lithium battery capacity attenuation, large volume change, etc., to achieve increased storage capacity, low resistivity, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

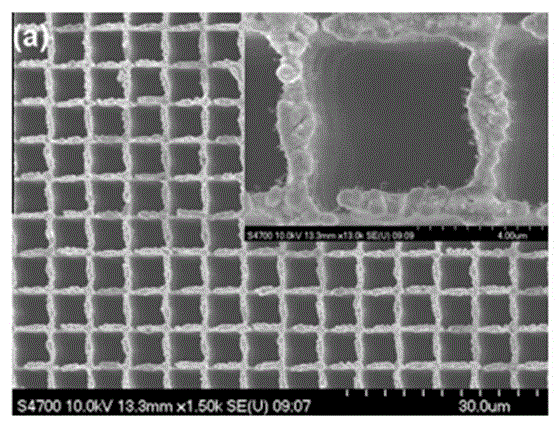

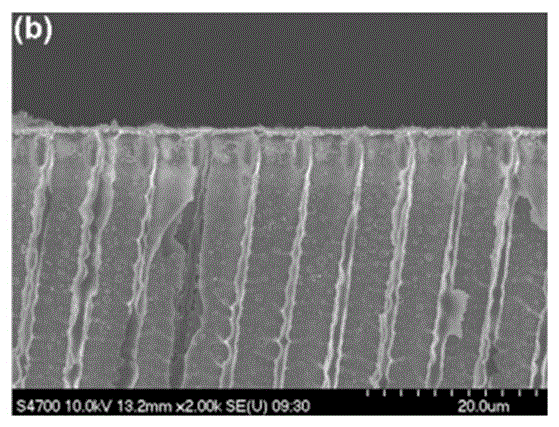

[0030] 1. Preparation of silicon microchannel substrate:

[0031] The preparation process of the electrochemical etching microchannel based on the MEMS process compatible with the traditional integrated circuit process has been elaborated in the patent application 200610025900. This program improves heavily doped low resistivity p-type silicon wafers, after standard cleaning process, dry oxidation at 1100 ℃ for 10 minutes, wet oxidation for 15 minutes, to generate 2000? SiO 2 Buffer layer; electrochemical etching temperature -20°C, light-assisted hole induction into LED lamps (blue light, 5W, 3 pieces), programmable power supply precisely controls the etching current density at 100mAcm -2 . The microchannel wells are square, with a side length of about 5 microns, a wall thickness of about 1 micron, and a depth of about 150 microns. The etching depth and width can be controlled by etching time, etchant, and temperature.

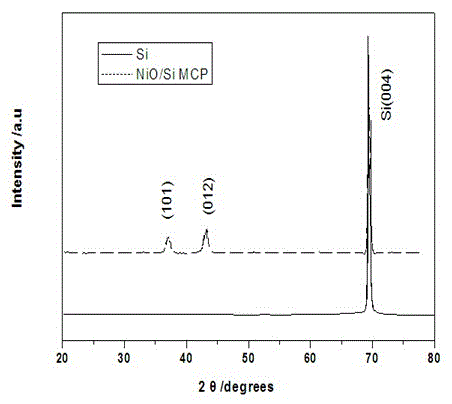

[0032] 2. Preparation of NiO / Si microchannel plate: ...

Embodiment 2

[0046] 1. Preparation of silicon microchannels:

[0047] The preparation process of the electrochemical etching microchannel based on the MEMS process has been described in detail in the patent application 200610025900.7. The microchannel wells are square, with a side length of about 5 microns, a wall thickness of about 1 micron, and a depth of about 150 microns. Its etching depth and width can be controlled by etching time, etchant and temperature.

[0048] 2. Preparation of NiO / Si microchannel plate:

[0049] Firstly, the silicon microchannel plate is cut into rectangular pieces with a size of about 1cm×1cm, and secondly, an electroplating solution is prepared, which is composed of sodium acetate, nickel sulfate, and sodium sulfate. Nickel sulfate is used as a source of nickel ions, sodium acetate is used as a complexing agent, and sodium sulfate is used as a buffer solvent. The plating solution was allowed to stand at room temperature. During the electroplating process,...

Embodiment 3

[0053] 1. Preparation of silicon microchannels:

[0054] The preparation process of the electrochemical etching microchannel based on the MEMS process has been described in detail in the patent application 200610025900.7. The microchannel hole is a square with a side length of about 5 microns, a wall thickness of about 1 micron, and a depth of about 150 microns. The etching depth and width can be controlled by etching time, etchant, and temperature.

[0055] 2. Preparation of NiO / Si microchannel plate

[0056] Firstly, the silicon microchannel plate is cut into rectangular pieces with a size of about 1cm×1cm, and secondly, an electroplating solution is prepared, which is composed of sodium acetate, nickel sulfate, and sodium sulfate. Nickel sulfate is used as a source of nickel ions, sodium acetate is used as a complexing agent, and sodium sulfate is used as a buffer solvent. The plating solution was allowed to stand at room temperature. During electroplating, the pH of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com