A kind of preparation method of kudzu active material herbicide microcapsule

A herbicide and material technology, which is applied in the field of preparation of kudzu active material herbicide microcapsules, can solve the problems of short retention time and high cost, and achieve the effects of high encapsulation rate, improved plasticity and excellent herbicidal performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

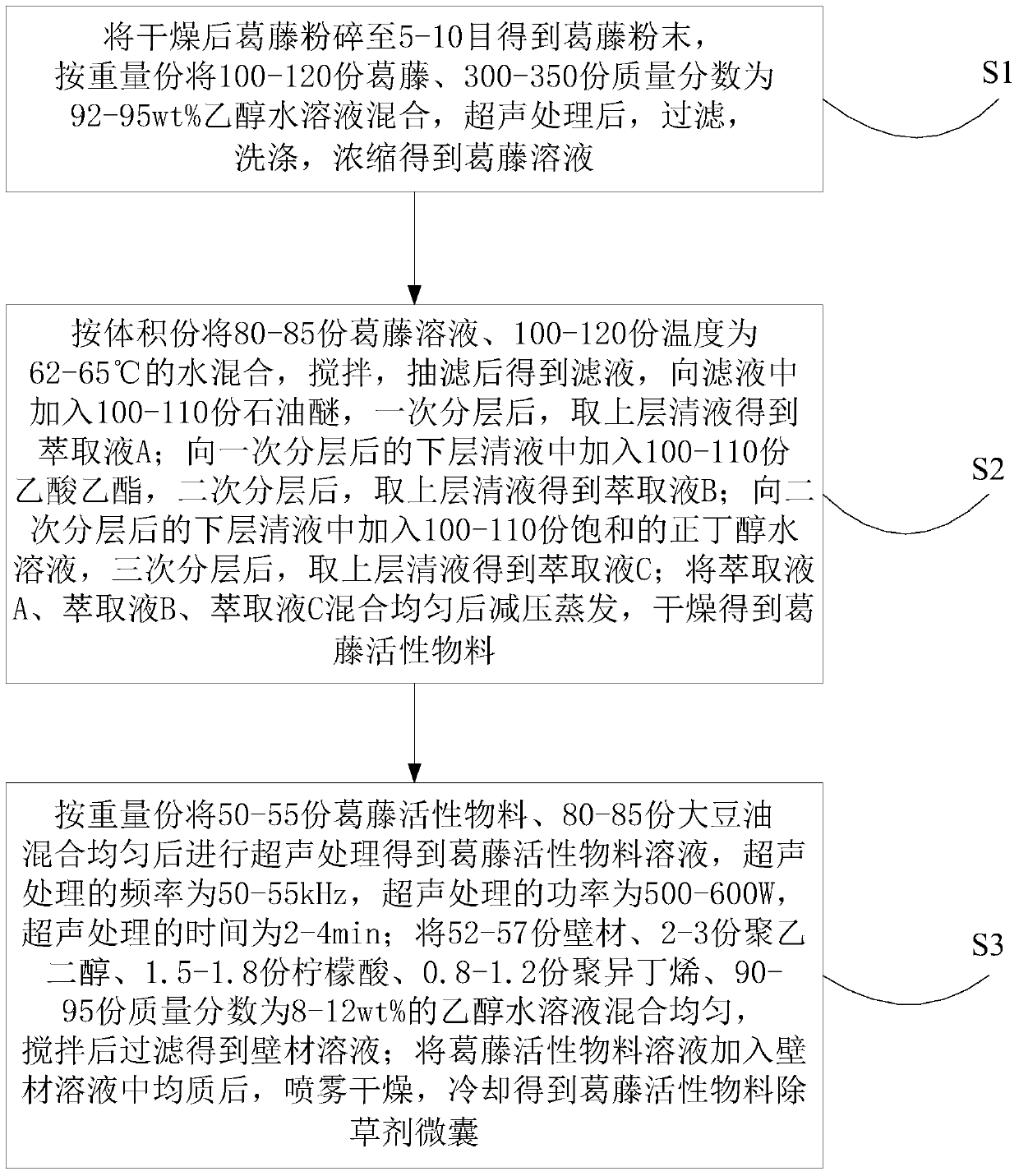

[0019] refer to figure 1 , the preparation method of a kind of kudzu active material herbicide microcapsule that the present invention proposes, comprises the following steps:

[0020] S1. Grinding the dried kudzu vine to 5-10 mesh to obtain kudzu vine powder. Mix 100-120 parts of kudzu vine and 300-350 parts of ethanol aqueous solution with a mass fraction of 92-95 wt% in parts by weight. After ultrasonic treatment, filter, wash and concentrate Obtain kudzu solution;

[0021] S2. Mix 80-85 parts of Pueraria vine solution and 100-120 parts of water at a temperature of 62-65°C in parts by volume, stir, and obtain the filtrate after suction filtration. Add 100-110 parts of petroleum ether to the filtrate. , take the supernatant to obtain extract A; add 100-110 parts of ethyl acetate to the lower clear after the first stratification, and after the second stratification, take the supernatant to obtain extract B; Add 100-110 parts of saturated n-butanol aqueous solution to the lo...

Embodiment 1

[0025] The preparation method of a kind of kudzu active material herbicide microcapsule that the present invention proposes comprises the following steps:

[0026] S1. Grinding the dried kudzu vine to 10 meshes to obtain kudzu vine powder. Mix 100 parts of kudzu vine and 350 parts of 92 wt% ethanol aqueous solution in parts by weight. After ultrasonic treatment, filter, wash, and concentrate to obtain kudzu vine solution; wherein, ultrasonic treatment The frequency is 65kHz, the power of ultrasonic treatment is 800W, and the time of ultrasonic treatment is 10min; the Baume degree of Pueraria vine solution is 31°Bé;

[0027] S2. Mix 85 parts of kudzu solution and 100 parts of water at a temperature of 65°C in parts by volume, stir, and obtain the filtrate after suction filtration, add 100 parts of petroleum ether to the filtrate, and after layering once, take the supernatant to obtain the extract A; Add 110 parts of ethyl acetate to the lower clear liquid after the first layeri...

Embodiment 2

[0030] The preparation method of a kind of kudzu active material herbicide microcapsule that the present invention proposes comprises the following steps:

[0031] S1. Pulverize kudzu vine after drying to 5 mesh to obtain kudzu vine powder, mix 120 parts kudzu vine and 300 parts mass fraction of 95wt% ethanol aqueous solution in parts by weight, after ultrasonic treatment, filter, wash, and concentrate to obtain kudzu vine solution; wherein, ultrasonic treatment The frequency is 60kHz, the power of ultrasonic treatment is 1000W, and the time of ultrasonic treatment is 7min; the Baume degree of Pueraria vine solution is 33°Bé;

[0032] S2. Mix 80 parts of kudzu solution and 120 parts of water at a temperature of 62°C in parts by volume, stir, and obtain the filtrate after suction filtration, add 1110 parts of petroleum ether to the filtrate, and after layering once, take the supernatant to obtain the extract A; Add 100 parts of ethyl acetate to the lower clear liquid after the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com