High protein feed producing method using orange peel residues as raw materials and feed

A high-protein feed and production method technology, applied in the field of feed production technology and the field of solid waste recycling, can solve problems such as the inability to meet animal husbandry, and achieve the effects of easy absorption and utilization, low cost and good palatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

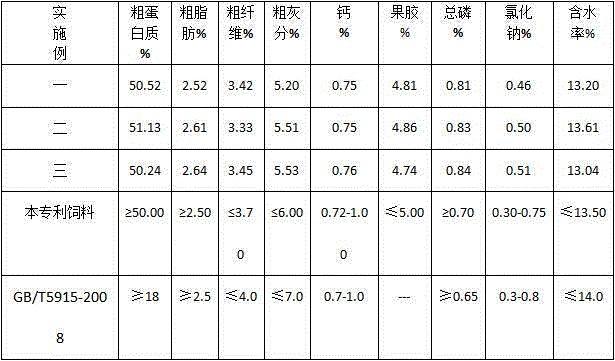

Embodiment 1

[0042] Adopt the following method to manufacture the high-protein feed with orange peel as raw material:

[0043] 1) Mixing: Grind citrus peel and wheat bran with a pulverizer, then mix orange peel residue, wheat bran and urea at a mass ratio of 100:20:1, pass through a 40-mesh sieve, and take the sieved material and mix it well. The fermentation substrate, wherein the orange peel is the orange peel that has not been dehydrated after the citrus industry squeezes the juice;

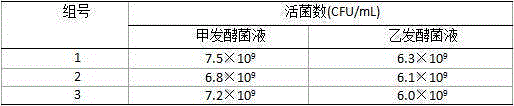

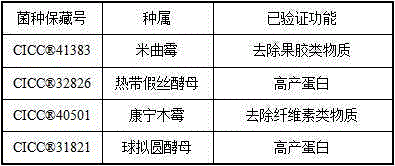

[0044] 2) One-stage fermentation: inoculate the fermented substrate prepared in step 1) with a fermentation broth at a mass ratio of 10:3 to form a one-stage fermentation material with a moisture content of 65.41%, and ferment it at 40°C for 72 hours to produce one-stage fermentation Fermented feed; stir the above-mentioned fermented material once every 8 hours, and stir for 25 minutes each time to ensure sufficient oxygen in contact with it; the solute of the fermented bacteria liquid used is Aspergillus ...

Embodiment 2

[0047] Adopt the following method to manufacture the high-protein feed with orange peel as raw material:

[0048] 1) Mixing: Grind citrus peel and wheat bran with a pulverizer, then mix orange peel residue, wheat bran and urea at a mass ratio of 105:21.20:1.05, pass through a 35-mesh sieve, and take the under-sieve material and mix it well. The fermentation substrate, wherein the orange peel is the orange peel that has not been dehydrated after the citrus industry squeezes the juice;

[0049] 2) One-stage fermentation: inoculate the fermented medium prepared in step 1) with a fermentation broth at a mass ratio of 10:3.52 to form a one-stage fermentation material with a moisture content of 67.80%, and ferment it at 38°C for 70 hours to produce one-stage fermentation Fermented feed; Stir the above-mentioned fermented material once every 8 hours, and stir for 23 minutes each time to ensure sufficient oxygen in contact with it; the solute of the fermented bacteria liquid used is A...

Embodiment 3

[0052] Adopt the following method to manufacture the high-protein feed with orange peel as raw material:

[0053] 1) Mixing: Grind citrus peel and wheat bran with a pulverizer, then mix orange peel residue, wheat bran, and urea at a mass ratio of 106:22:1.21, pass through a 30-mesh sieve, and take the under-sieve material and mix it well. The fermentation substrate, wherein the orange peel is the orange peel that has not been dehydrated after the citrus industry squeezes the juice;

[0054] 2) One-stage fermentation: Inoculate the fermentation substrate prepared in step 1) with a fermentation broth at a mass ratio of 10:4 to form a one-stage fermentation material with a water content of 63.56%, and ferment it at 35°C for 66 hours to produce one-stage fermentation Fermented feed; stir the above-mentioned fermented material once every 8 hours, and stir for 24 minutes each time to ensure sufficient oxygen in contact with it; the solute of the fermented bacteria liquid used is Asp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com