Composition of probiotic fermented ginseng and its preparation method and application

A technology for fermenting ginseng and probiotics, applied in the directions of bacteria, applications, and food ingredients containing inorganic compounds used in food preparation, can solve the problems of weak biotransformation efficiency of ginsenosides, difficult to industrialized large-scale production, and poor product stability. Significant growth-promoting effect, obvious inhibitory effect, and effect of improving gastrointestinal function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

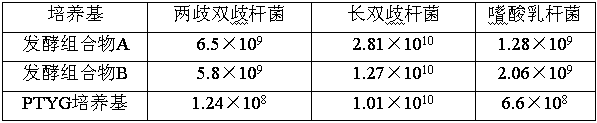

[0030] Example 1: Preparation of probiotic fermented ginseng composition A

[0031] Take 30g of dried ginseng, crush it through a 100-mesh sieve, add 35 times of water to soak for 30 minutes, and extract under high pressure at 115°C for 40 minutes, reduce the temperature of the raw material liquid to 90°C, and add 0.5% glucose (weight / volume), inorganic salts (ferrous sulfate 7H 2 O5.0mg / 100ml, zinc sulfate 7H 2 O 4.4mg / 100ml, magnesium sulfate 7H 2O 50mg / 100ml, potassium dihydrogen phosphate 100mg / 100ml, dipotassium hydrogen phosphate 3H 2 O 100mg / 100ml), sucrose 3.0g / 100ml, sucralose 0.008g / 100ml. Adjust the pH to 7.0 and sterilize at 115°C for 40 minutes to obtain the ginseng fermentation substrate. When the temperature of the fermentation substrate drops to about 39°C, insert the pre-cultured Bifidobacterium bifidum (isolated from normal human body, identified by the Institute of Microbiology, Chinese Academy of Sciences) and Bifidobacterium breve (AS 1.2213) bacteri...

Embodiment 2

[0032] Embodiment 2: Preparation of probiotic fermented ginseng composition B

[0033] Take 100g of dried ginseng, crush it through a 20-mesh sieve, add 10 times of water to soak for 60 minutes, and extract under high pressure at 115°C for 120 minutes, reduce the temperature of the raw material liquid to 85-90°C, and adjust the pH to 5.5 with sodium hydroxide Add 3000 units of high-temperature amylase (according to 30 units of amylase / g of ginseng powder), dilute the enzyme with water when adding, stir the feed liquid evenly, and maintain the temperature at 85-90°C. When the indicator iodine solution and enzymolysis solution The reaction does not turn blue obviously, the reaction is terminated, and the enzyme is extinguished at 100°C for 10 minutes to obtain the raw material enzymolysis solution. Add glucose 0.5% (weight / volume), inorganic salt (ferrous sulfate 7H 2 O5.0mg / 100ml, zinc sulfate 7H 2 O 4.4mg / 100ml, magnesium sulfate 7H 2 O 50mg / 100ml, potassium dihydrogen phosp...

experiment example 1

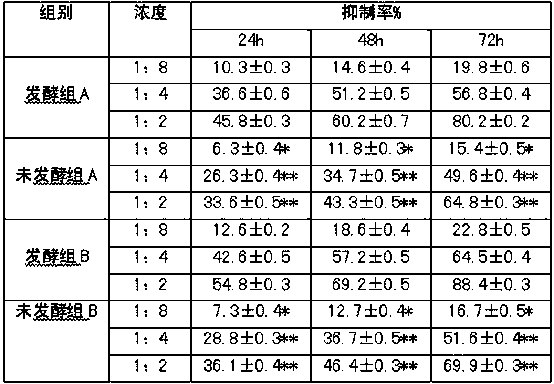

[0034] Experimental example 1: In vitro inhibition of tumor cell proliferation by probiotic fermented ginseng composition and unfermented composition

[0035] The composition of probiotic fermented ginseng prepared in Example 1 and Example 2 was selected, and the composition without probiotic fermentation was used as a control.

[0036] Take the HeLa (human cervical cancer cell) line cells in the logarithmic growth phase, inoculate the cells in a 96-well culture plate, add 100 μl of culture medium containing 5000 cells to each well, pre-culture for 24 hours, add various concentrations of probiotics to ferment ginseng Fermented vs. unfermented compositions (both samples were double diluted). Three replicate wells were set up for each concentration and blank control. After culturing for 24, 48 and 72 hours respectively, add 10 μl of CCK-8 solution and culture for another 2 hours. Then, measure the A value of each well at 450nm with an enzyme-linked immunoassay instrument, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com