Meclizine hydrochloride oral rapid-release film agent and preparation method thereof

A technology of meclizine hydrochloride and oral cavity, which is applied in the field of oral immediate-release film of meclizine hydrochloride and its preparation, and can solve the problem of different technical solutions, different effects, and no meclizine hydrochloride Problems such as oral immediate-release film technology solutions, to achieve the effects of low viscosity, easy hydration, and improved drug compliance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

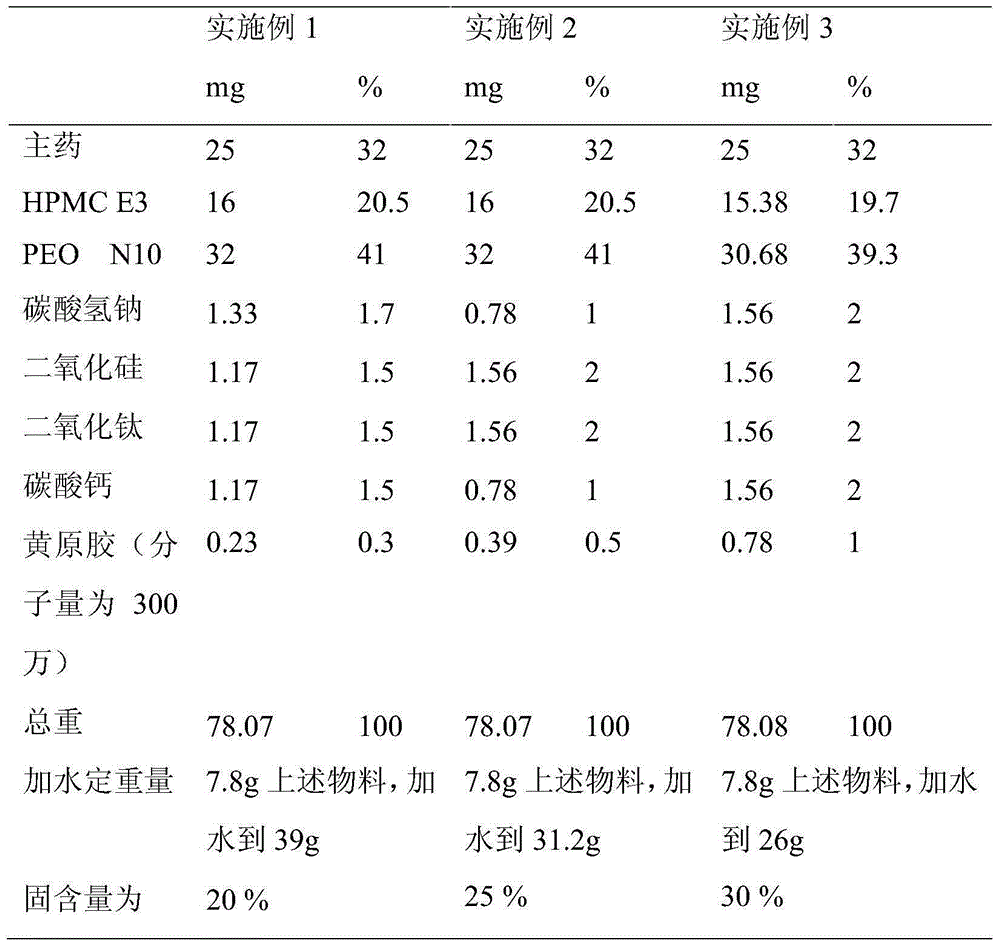

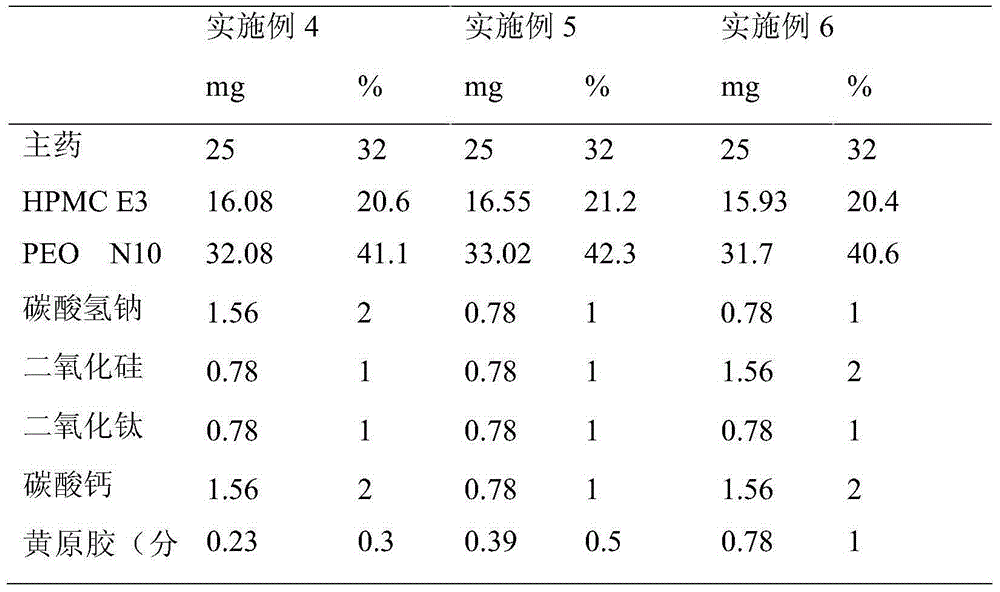

preparation example Construction

[0037] The preparation method of embodiment 1~15 is identical, and step is as follows:

[0038] (1) Raw and auxiliary materials pass through a 200-mesh drug sieve;

[0039] (2) Disperse the xanthan gum with 10mL of water, and swell evenly to obtain a xanthan gum solution; disperse the bulk drug in 5mL of water, and disperse evenly to obtain a bulk drug solution;

[0040] (3) Mix HPMC and PEO, uniformly disperse them in about 15mL of water, stir to make them swell and dissolve; add sodium bicarbonate, calcium carbonate, silicon dioxide, titanium dioxide, and raw material drug solution in turn, and carry out vacuum emulsification in a vacuum emulsifier. Emulsify for 30 minutes to make it evenly dispersed; then add xanthan gum solution, stir in vacuum for 20 minutes to make it uniform, degas, and let stand to obtain a film-forming solution;

[0041] (4) The film-forming solution is evenly coated on a glass plate with a polyester-polyethylene backing, and dried in a water bath at...

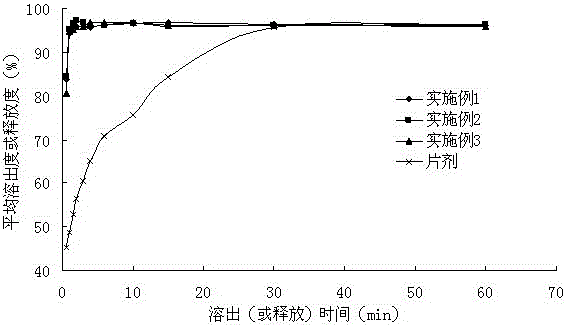

experiment example 1

[0081] Study the characteristics of three models of HPMC, E15, E5, and E3 (model E indicates the dynamic viscosity of its 2% aqueous solution at 20°C)

[0082] The viscosity of the above three film-forming materials is low and easy to hydrate, which can maximize the film-forming properties of the product and shorten the dissolution time of the product. The dissolution of the film obtained by the simple three HPMC (E15, E5, E3) The performance is far from the requirements of oral instant film.

[0083] After the film is made, the film is laid on the backing of various materials such as silicone oil paper, coated paper, kraft paper, glass plate, polyester-polyethylene, polyester-Al-polyethylene, etc. It is found that when polyester-polyethylene and polyester-Al-polyethylene are used as the backing, the film-forming solution can self-level smoothly, and the film is relatively easy to form. The difference between the two is not large, so polyester-polyethylene is selected as the b...

experiment example 2

[0085] Comprehensive evaluation of HPMCE15, E5, E3 combined with PEON10, N80 film-forming solution solution on polyester-polyethylene backing, film-forming situation, filming situation.

[0086] The results show that: HPMCE15, E5, E3 and PEON10 (molecular weight of 100,000), N80 (molecular weight of 200,000) combined film-forming solution on the polyester-polyethylene backing have relatively large differences in film formation and film formation. The combination of E3, E5 and PEON10, N80, the self-leveling effect of the solution is too large, and the film thickness cannot be well controlled. With the increase of the HPMC viscosity specification, the decrease of the molecular weight and the increase of the content of PEO, the toughness and density of the film after film formation are greater; but at the same time, it is found that the viscosity of the film-forming solution is also increasing with the increase of the HPMC viscosity specification. The self-leveling phenomenon i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com