Rare earth ore collecting agent and preparation method and application thereof

A collector and rare earth ore technology, applied in solid separation, flotation, etc., can solve the problems of poor selectivity of reagents, lower recovery rate of rare earth, difficulty in meeting product requirements of rare earth concentrate grade, etc., to achieve reduced dosage and good environmental adaptation Sexuality, selectivity and excellent results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

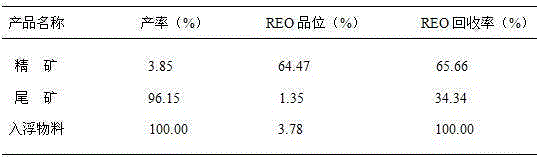

Embodiment example 1

[0033] The rare earth ore positive flotation collector is composed of the following mass ratio materials: 50 parts of octyl alkyl hydroxamic acid, 10 parts of naphthalene methyl hydroxamic acid, 10 parts of salicylic hydroxamic acid, 14 parts of iodine value 90-120 oleic acid, 4.25 parts of Span-80.

[0034] Will C 8Add 50kg of fatty acid, 10kg of naphthoic acid, 10kg of salicylic acid and 8kg of methanol into the enamel reaction kettle, stir evenly, add 2.3kg of concentrated sulfuric acid (accounting for 3% of the total weight), install the cooling reflux device, and start the heating reflux reaction After 20 hours, the product was centrifuged to obtain liquid mixed carboxylate, and the paste was discarded after treatment; 15kg of the obtained liquid mixed carboxylate and 6.5kg of 15% hydroxylamine sulfate aqueous solution (molar ratio 1:0.55) were added to the enamel In the reaction kettle, dropwise add a 30% sodium hydroxide aqueous solution while stirring, keep the pH val...

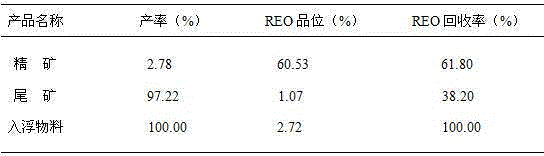

Embodiment example 2

[0039] This rare earth ore positive flotation collector is composed of the following mass ratio materials: 70 parts of octyl alkyl hydroxamic acid, 10 parts of naphthalene methyl hydroxamic acid, 10 parts of salicylic hydroxamic acid, 17.5 parts of iodine value 90-120 soybean oleic acid, 2.8 parts of Span-80.

[0040] Will C 8 Add 70Kg of fatty acid, 10kg of naphthoic acid, 10kg of salicylic acid and 8kg of methanol into the enamel reaction kettle. After stirring evenly, add 4.5kg of concentrated sulfuric acid, install the cooling reflux device, and start the heating and reflux reaction for 25 hours. Obtain liquid mixed carboxylate, throw away after paste treatment; Get 15kg and massfraction in the liquid mixed carboxylate of gained and be 10% hydroxylamine sulfate aqueous solution 6.8kg and add in the enamel reaction kettle, add dropwise massfraction while stirring It is 35% sodium hydroxide aqueous solution, keep the pH value in the reaction kettle not less than 11, control...

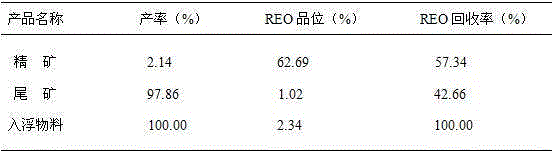

Embodiment example 3

[0045] The rare earth ore positive flotation collector is composed of the following mass ratio materials: 50 parts of octyl alkyl hydroxamic acid, 10 parts of naphthalene methyl hydroxamic acid, 20 parts of salicylic hydroxamic acid, 17.8 parts of iodine value 90-120 oleic acid, 4.4 parts span-80.

[0046] Will C 8 Add 50Kg of fatty acid, 10Kg of naphthoic acid, 20Kg of salicylic acid and 9Kg of methanol into the enamel reaction kettle. After stirring evenly, add 8kg of concentrated sulfuric acid, install a cooling reflux device, and heat and reflux for 25 hours. Mixed carboxylate, discarded after paste treatment; get 15kg and 7.3kg of hydroxylamine sulfate aqueous solution with a mass fraction of 15% in the obtained liquid mixed carboxylate and add it to the enamel reaction kettle, and add it dropwise with a mass fraction of 35% while stirring. % sodium hydroxide aqueous solution, keep the pH value in the reactor not less than 11, control the reaction temperature at 55 ° C, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com