Water treatment agent for spinning and preparation method therefor

A water treatment agent and additive technology, applied in water/sludge/sewage treatment, chemical instruments and methods, complexes/solubilizer treatment, etc., can solve problems such as poor decolorization effect and easy scaling in the treatment process, and achieve Low cost reduction, scaling problem solving, strong adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

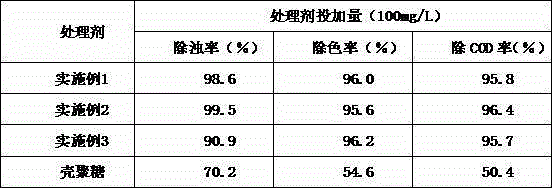

Examples

Embodiment 1

[0019] Textile water treatment agent, composed of agent A and agent B in a mass ratio of 1:1,

[0020] Agent A is prepared from the following raw materials in parts by weight: 16 parts of aluminum hydroxide gel, 12 parts of chitosan, 10 parts of lime, 8 parts of sodium polyepoxysuccinate, 3 parts of cornstarch, 2 parts of sodium gluconate, 2 parts of sodium lignosulfonate, 3 parts of activated carbon, 2 parts of corrosion inhibitor, and 1.2 parts of powder additive.

[0021] The powder additive is a mixture of fly ash, zeolite and diatomaceous earth in a weight ratio of 2:3:5.

[0022] The corrosion inhibitor is mixed with aloe vera and cactus at a mass percentage of 1:3, crushed and stirred, soaked in deionized water for 12 days, and concentrated to 25% of the filtered soaking solution.

[0023] Agent B is prepared from the following raw materials in parts by weight: 15 parts of sodium metaaluminate, 4 parts of ferric chloride hexahydrate, 5 parts of ferrous sulfate heptahyd...

Embodiment 2

[0025] Textile water treatment agent, composed of agent A and agent B in a mass ratio of 1:1,

[0026] Agent A is prepared from the following raw materials in parts by weight: 17 parts of aluminum hydroxide gel, 13 parts of chitosan, 11 parts of lime, 10 parts of sodium polyepoxysuccinate, 4 parts of cornstarch, 3 parts of sodium gluconate, 3 parts of sodium lignosulfonate, 4 parts of activated carbon, 3 parts of corrosion inhibitor, and 1.4 parts of powder additive.

[0027] The powder additive is a mixture of fly ash, zeolite and diatomaceous earth in a weight ratio of 2:3:5.

[0028] The corrosion inhibitor is mixed with aloe vera and cactus at a mass percentage of 1:2, crushed and stirred, soaked in deionized water for 12 days, and concentrated to 25% of the filtered soaking solution.

[0029] Agent B is prepared from the following raw materials in parts by weight: 17 parts of sodium metaaluminate, 6 parts of ferric chloride hexahydrate, 3 parts of ferrous sulfate heptahy...

Embodiment 3

[0031] Textile water treatment agent, composed of agent A and agent B in a mass ratio of 1:2,

[0032] Agent A is prepared from the following raw materials in parts by weight: 18 parts of aluminum hydroxide gel, 14 parts of chitosan, 12 parts of lime, 12 parts of sodium polyepoxysuccinate, 3 parts of cornstarch, 4 parts of sodium gluconate, 2 parts of sodium lignosulfonate, 5 parts of activated carbon, 4 parts of corrosion inhibitor, and 1.5 parts of powder additive.

[0033] The powder additive is a mixture of fly ash, zeolite and diatomaceous earth in a weight ratio of 2:3:5.

[0034] The corrosion inhibitor is mixed with aloe vera and cactus at a mass percentage of 1:3, crushed and stirred, soaked in deionized water for 12 days, and concentrated to 20% of the soaking solution obtained by filtration.

[0035] Agent B is prepared from the following raw materials in parts by weight: 20 parts of sodium metaaluminate, 8 parts of ferric chloride hexahydrate, 3 parts of ferrous s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com