Simple and convenient resorcinol formaldehyde resin hollow composite material and preparing method of derivative thereof

A technology of resorcinol-formaldehyde resin and composite materials, which is applied in the field of preparation of resorcinol-formaldehyde resin hollow composite materials and derivatives thereof, and can solve the problems of difficult structure control, high cost and high density of resorcinol-formaldehyde resin and other problems, to achieve the effect of good dispersion, simple preparation method and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

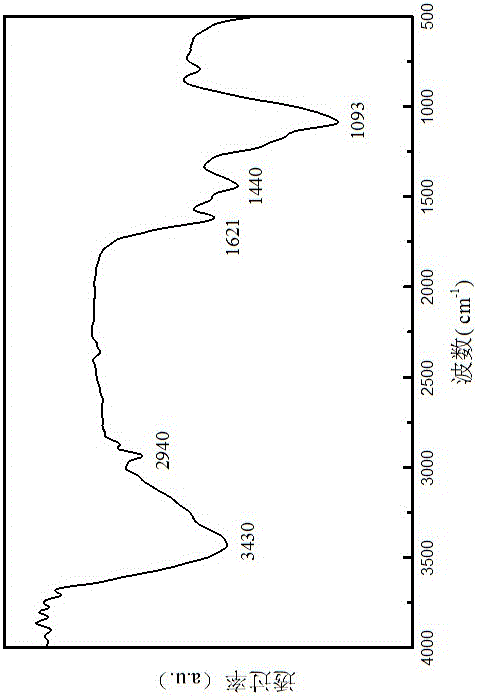

Image

Examples

specific Embodiment approach 1

[0020] Embodiment 1: The preparation method of the resorcinol-formaldehyde resin hollow composite material and its derivatives provided in this embodiment is carried out according to the following steps:

[0021] 1. Soak the hollow glass microspheres in sodium hydroxide solution for 1.5 hours, wash with distilled water and dry to obtain the hollow glass microspheres after alkali washing; wherein, the concentration of the sodium hydroxide solution is 1.5mol / L;

[0022] Two, absolute ethanol and distilled water are configured ethanol solution according to the dosage ratio of 300g:98g, and mix under the condition of stirring;

[0023] 3. Disperse the hollow glass microspheres after alkali washing and the cationic surfactant in the above-mentioned ethanol solution in sequence; wherein, the cationic surfactant is cetyltrimethylammonium bromide, and the hollow glass after alkali washing The dosage ratio of microspheres to cetyltrimethylammonium bromide is 0.1g:0.75g, and the dispers...

specific Embodiment approach 2

[0030] Specific embodiment two: the preparation method of the resorcinol-formaldehyde resin hollow composite material and its derivatives provided by this embodiment is carried out according to the following steps:

[0031] 1. Soak the hollow glass microspheres in sodium hydroxide solution for 1.5 hours, wash with distilled water and dry to obtain the hollow glass microspheres after alkali washing; wherein, the concentration of the sodium hydroxide solution is 1mol / L;

[0032] Two, absolute ethanol and distilled water are configured ethanol solution according to the dosage ratio of 300g:60g, and mix under the condition of stirring;

[0033] 3. Disperse the hollow glass microspheres after alkali washing and the cationic surfactant in the above-mentioned ethanol solution in sequence; wherein, the cationic surfactant is cetyltrimethylammonium bromide, and the hollow glass after alkali washing The dosage ratio of microspheres to cetyltrimethylammonium bromide is 0.1g:0.75g, and th...

specific Embodiment approach 3

[0038] Specific embodiment three: the preparation method of the resorcinol-formaldehyde resin hollow composite material and its derivatives provided by this embodiment is carried out according to the following steps:

[0039] 1. Soak the hollow glass microspheres in sodium hydroxide solution for 1.5 hours, wash with distilled water and dry to obtain the hollow glass microspheres after alkali washing; wherein, the concentration of the sodium hydroxide solution is 0.8mol / L;

[0040] Two, absolute ethanol and distilled water are configured ethanol solution according to the dosage ratio of 300g:80g, and mix under the condition of stirring;

[0041] 3. Disperse the hollow glass microspheres after alkali washing and the cationic surfactant in the above-mentioned ethanol solution in sequence; wherein, the cationic surfactant is cetyltrimethylammonium bromide, and the hollow glass after alkali washing The dosage ratio of microspheres to cetyltrimethylammonium bromide is 0.4g:0.75g, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com