Friction-reduction and antiwear solid lubrication material and preparation method thereof

A solid lubricating material, anti-friction and anti-wear technology, used in lubricating compositions, petroleum industry, etc., can solve problems such as poor adhesion, achieve strong adhesion, excellent anti-friction and anti-wear, and improve service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

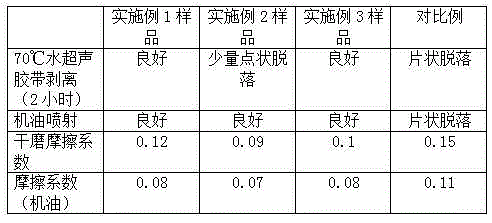

Embodiment 1

[0019] Example 1: Spray treatment of graphite or molybdenum disulfide with a particle size of 3-10 μm with monoalkoxy tris(dioctylphosphoryloxy) titanate, and then vacuum bake at 140° C. for 4 hours to make The titanate end group reacts with the hydroxyl groups on the surface of graphite or molybdenum disulfide; for graphene oxide with a thickness of less than 1nm and a diameter of 100nm-1μm, vacuum bake at 80°C for 4 hours to remove surface water; use γ-aminopropyl Carbon fibers with a width of 7 μm and an aspect ratio of 7 were sprayed with triethoxysilane, and ground on a planetary ball mill for 2 hours to promote the coupling dehydration reaction between the silane end groups and the carbon fiber surface groups, and then heated at 140 ° C Bake in vacuum for 4 hours; for TiO with a rutile particle size of 20-100nm 2 The particles were baked in vacuum at 140°C for 4 hours to remove moisture. Get 15 parts of treated graphite, 0.05 part of graphene oxide, 2 parts of carbon fi...

Embodiment 2

[0020] Embodiment 2: The similarities between this embodiment and Embodiment 1 will not be repeated, and the difference is to get 10 parts of processed graphite, 5 parts of molybdenum disulfide, 0.1 part of graphene oxide, 0.5 part of carbon fiber, TiO 2 1 part of particles, 40 parts of polyamideimide resin with a mass concentration of 30%, 0.4 parts of polypropylene glycol-modified polysiloxane with a molecular weight of 500-800, and 0.4 parts of double-effect active polysiloxane are added to the planetary ball mill Grinding at high speed for 40 minutes, and then filtering with a 100-mesh filter to obtain a friction-reducing and anti-wear solid lubricating material.

Embodiment 3

[0021] Embodiment 3: present embodiment and embodiment 1 similarity no longer go into details, and difference is to get 13 parts of processed graphite, 2 parts of molybdenum disulfide, 0.03 part of graphene oxide, 1 part of carbon fiber, TiO 2 1 part of particles, 40 parts of polyamideimide resin with a mass concentration of 30%, 0.4 parts of polypropylene glycol-modified polysiloxane with a molecular weight of 500-800, and 0.4 parts of double-effect active polysiloxane are added to the planetary ball mill Grinding at high speed for 40 minutes, and then filtering with a 100-mesh filter to obtain a friction-reducing and anti-wear solid lubricating material.

[0022] Comparative example: get 12 parts of untreated graphite, 5 parts of molybdenum disulfide, 5 parts of carbon fiber, 28 parts of polyamide-imide resins with mass concentration at 30%, molecular weight is the polypropylene glycol modified polysilicon of 500-800 Add 1 part of oxane and 1 part of double-effect active pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com