Chitosan hydrolysis method

A technology of chitosan and dissolving solution, applied in the field of cellulase hydrolysis of chitosan, can solve problems such as low efficiency, and achieve the effects of good water solubility and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1 Hydrolysis of Chitosan

[0028] The invention discloses a method for hydrolysis of chitosan, which uses chitosan as raw material, uses binary mixed ionic liquid as solvent of chitosan, uses cellulase as catalyst for hydrolysis, and conducts hydrolysis reaction under constant temperature oscillation reaction conditions.

[0029] The hydrolysis method of above-mentioned chitosan, comprises the steps:

[0030] Step 1: Dissolution of Chitosan

[0031] Dissolve chitin or chitosan in the binary mixed ionic liquid, heat it to 80-130°C under stirring for a period of time until the solution is transparent, the concentration of chitosan in the binary mixed ionic liquid is 5wt%, and cool to room temperature Then add water with 5 times the molar weight of chitosan and cellulase with a weight of 5% of the weight of chitosan, adjust the pH of the solution, and stir at room temperature for 0.5-1 h to obtain a solution of chitosan.

[0032] Step 2: Hydrolysis of Chitosan

...

Embodiment 2

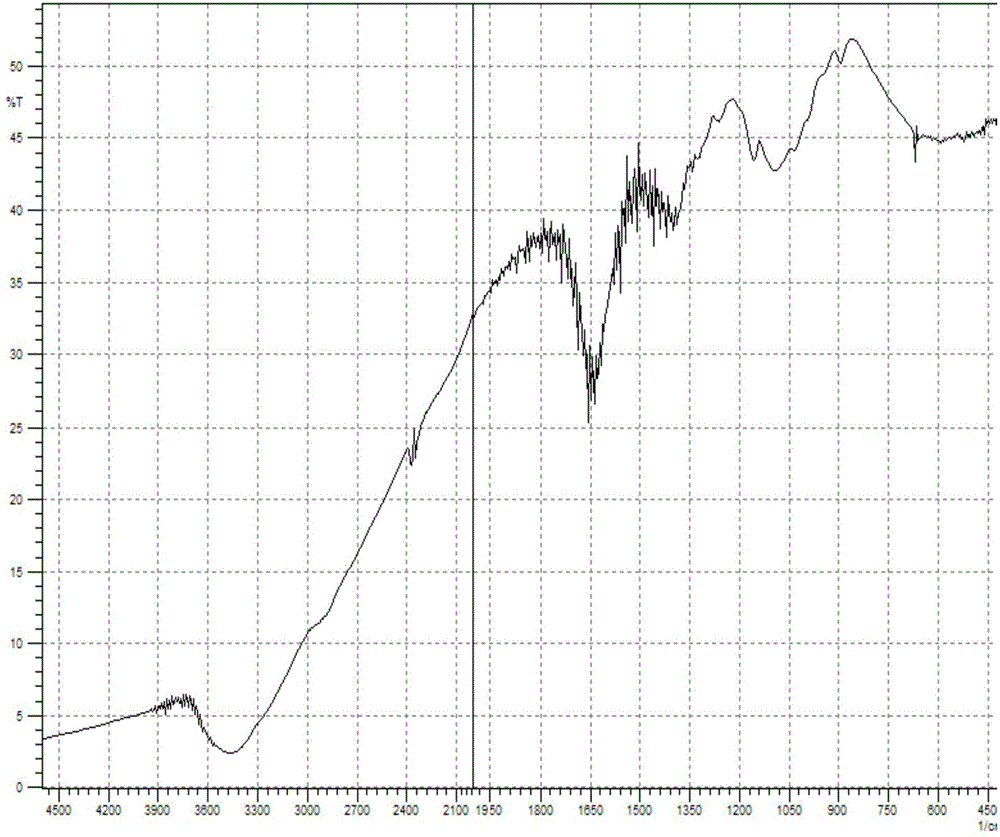

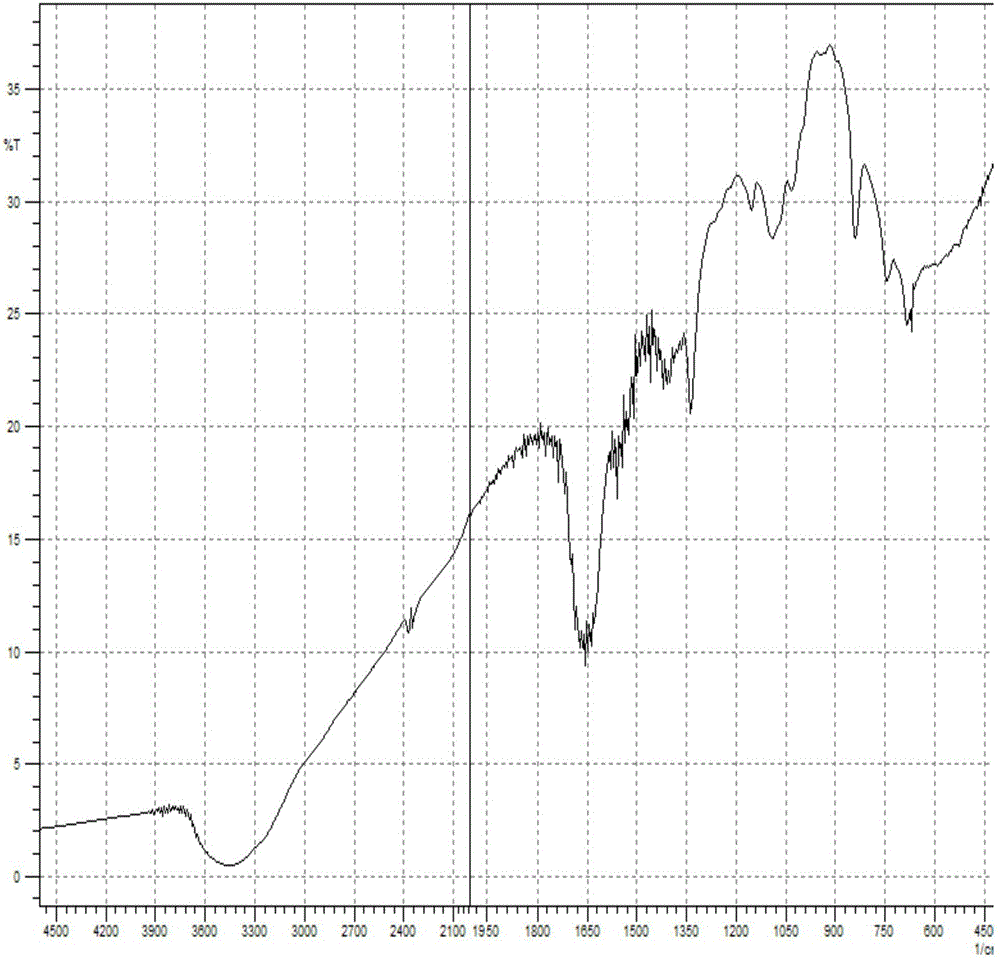

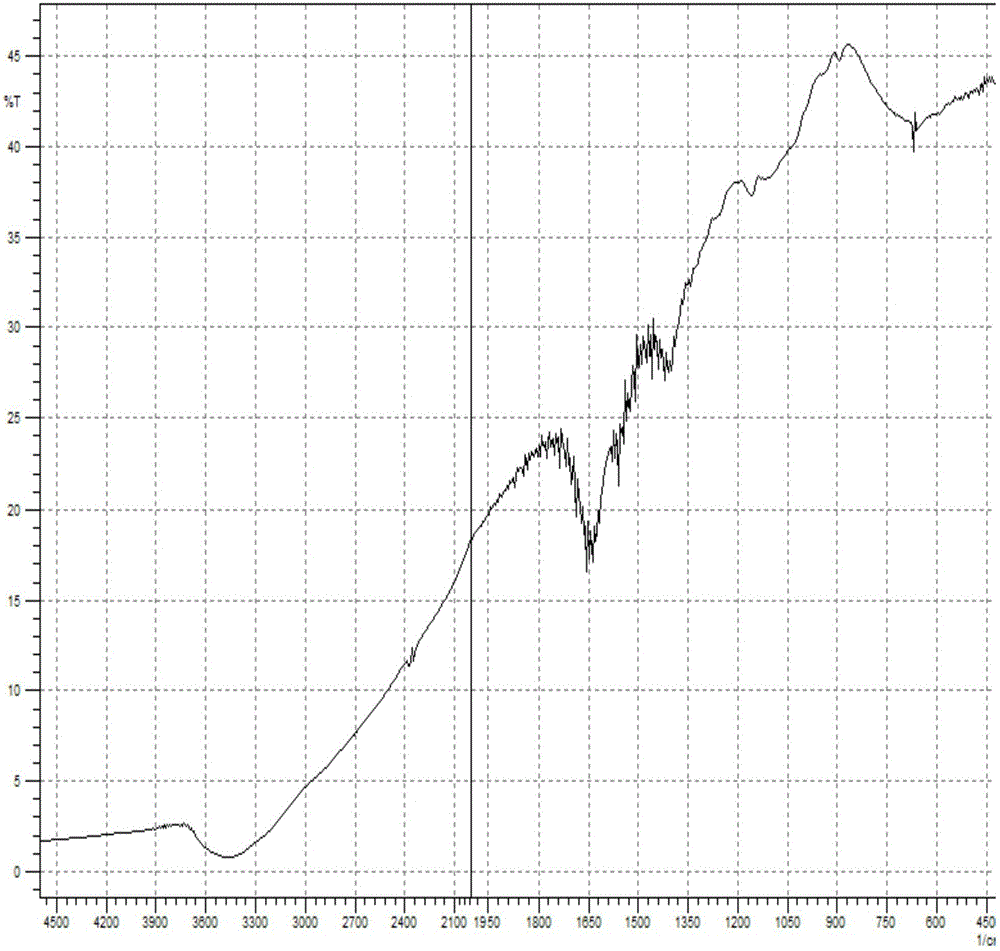

[0034] Example 2 Characterization of Chitosan after Hydrolysis

[0035] The chitosan after enzymatic hydrolysis was centrifuged, and the precipitate was vacuum-dried. A small amount of the product was mixed with potassium bromide and pressed into tablets, and the infrared spectrum was measured by Fourier transform infrared spectrometer. The degree of deacetylation after hydrolysis was analyzed according to the infrared spectrum. At the same time, measure the deacetylation degree of raw chitosan, which is still insoluble in water after enzymatic hydrolysis, and compare it with the infrared image of water-soluble chitosan. The following calculation formula is used:

[0036] A=-logT, where T is the transmittance (%);

[0037] DD=(A 1560 / A 2880 -1.951) / -0.0148×100%;

[0038] In the above formula, A is the absorbance (%); DD is the deacetylation degree (%).

[0039] Figure 1 to Figure 3 Infrared spectra of chitosan before and after cellulase degradation and precipitation o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com