Method for preparing water-soluble polyimide sizing agent for polyimide fiber and application thereof

A technology of polyimide fiber and polyimide, applied in the field of preparation and application of high-performance organic fiber sizing agent, can solve the problems of preparation and application methods that have not been reported in the literature, and achieve improved wettability and interfacial bonding strength , improve wear resistance and clustering, and improve the effect of surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

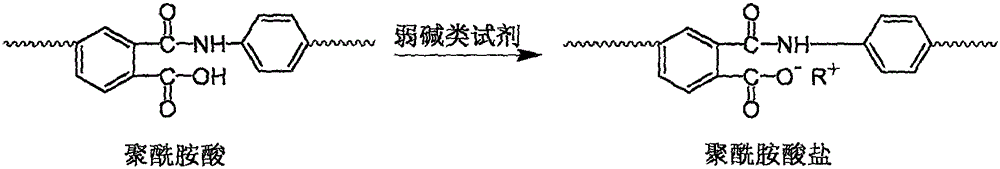

[0026] A. Add triethylamine to the polyamic acid solution, and make it fully react to form polyamic acid salt under continuous stirring. The molar ratio of triethylamine to carboxyl in polyamic acid is 1:1;

[0027] B. Precipitate the polyamic acid salt solution obtained in step A in an acetone solution, dry and remove residual solvent after repeated washing, and obtain a polyamic acid salt solid;

[0028] C, dissolving the solid obtained in step B in a deionized aqueous solution at a concentration of 8 wt%, to obtain the sizing agent of the present invention;

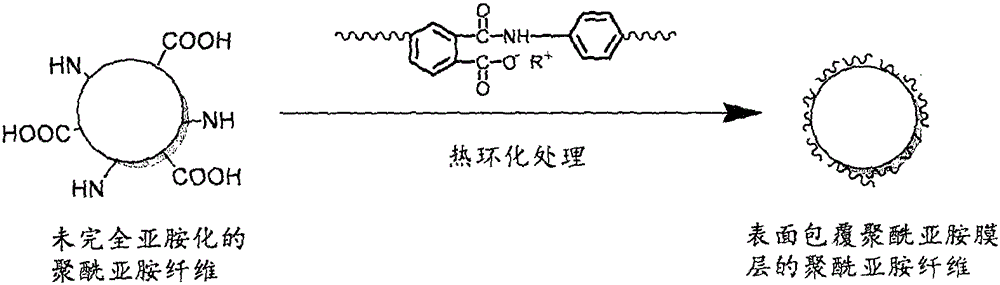

[0029] D. Dilute the sizing agent obtained in step C to a concentration of 2wt%, and place it in a polyimide fiber production line. After the fibers are fully immersed in the solution, they are dehydrated in a high-temperature furnace and fully cyclized to obtain polyimide on the surface. Polyimide fibers coated with macromolecular chains.

Embodiment 2

[0031] A. Add triethanolamine to the polyamic acid solution, and make it fully react to form polyamic acid salt under continuous stirring. The molar ratio of carboxyl groups in triethanolamine and polyamic acid is 1:1;

[0032] B. Precipitate the polyamic acid salt solution obtained in step A in a blended solution of acetone and methanol, and dry to remove residual solvent after repeated washing to obtain a polyamic acid salt solid;

[0033] C, dissolving the solid obtained in step B in a deionized aqueous solution at a concentration of 12 wt%, to obtain the sizing agent of the present invention;

[0034] D. Dilute the sizing agent obtained in step C to a concentration of 2.5wt%, and place it in a polyimide fiber production line. After the fiber is fully immersed in the solution, it is dehydrated in a high-temperature furnace and fully cyclized to obtain polyimide on the surface. Polyimide fibers coated with amine macromolecular chains.

Embodiment 3

[0036] A. Add tripropylamine to the polyamic acid solution, and make it fully react to form polyamic acid salt under continuous stirring. The molar ratio of carboxyl in tripropylamine to polyamic acid is 0.5:1;

[0037] B. Precipitate the polyamic acid salt solution obtained in step A in methanol solution, dry and remove residual solvent after repeated washing, and obtain polyamic acid salt solid;

[0038] C, dissolving the solid obtained in step B in a deionized aqueous solution at a concentration of 6 wt%, to obtain the sizing agent of the present invention;

[0039] D. Dilute the sizing agent obtained in step C to a concentration of 2.5wt%, and place it in a polyimide fiber production line. After the fiber is fully immersed in the solution, it is dehydrated in a high-temperature furnace and fully cyclized to obtain polyimide on the surface. Polyimide fibers coated with amine macromolecular chains.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com