Method for determining content of iron in nickel-based high temperature alloy

A technology for nickel-based superalloy and iron content, which is applied in the direction of chemical analysis by titration, which can solve the problems of time-consuming and labor-intensive, environmental pollution of waste liquid production, and complicated steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

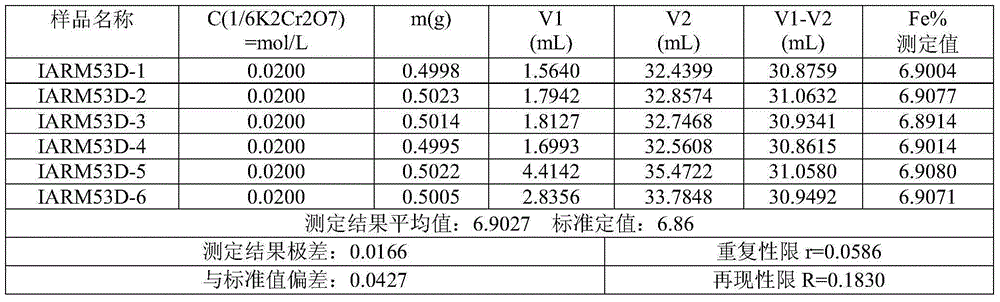

Embodiment 1

[0089] Take by weighing 0.5000g of nickel base superalloy sample 1# (IARM53D, standard fixed value: 6.86%), add the mixed acid solution (wherein, hydrochloric acid solution, nitric acid solution The volume ratio of the added amount is = 6-8:1, and the volume ratio of the added amount of hydrochloric acid solution, nitric acid solution, and hydrofluoric acid solution is 150-400:25-50:3, so that the added amount of hydrochloric acid solution is about 35.5ml, The amount of nitric acid solution added is about 4.5ml, and the amount of hydrofluoric acid solution added is about 0.25ml), and heated and dissolved at 120°C for 5 hours to completely dissolve the sample. Then add 20ml of 70-72% perchloric acid solution to heat and reflux for 4 minutes to oxidize the chromium and iron elements in the nickel-based superalloy and dehydrate the niobic acid. After heating to reflux, evaporate to nearly dryness, and after cooling slightly, dissolve the soluble salts in the sample with 200ml of ...

Embodiment 2

[0093] Take by weighing 0.5000g of nickel base superalloy sample 2# (IARM53D, standard fixed value: 6.86%), add the mixed acid solution (wherein, hydrochloric acid solution, nitric acid solution The volume ratio of the amount added is = 7:1, and the volume ratio of the amount of hydrochloric acid solution, nitric acid solution, and hydrofluoric acid solution is 175-350:25-50:3, so that the amount of hydrochloric acid solution added is about 35ml, and the amount of nitric acid solution added The amount is about 5ml, and the amount of hydrofluoric acid solution is about 0.3ml), and heated and dissolved at 150°C for 4 hours to completely dissolve the sample. Then add 10ml of 70-72% perchloric acid solution to heat and reflux for 5 minutes to oxidize the chromium and iron elements in the nickel-based superalloy and dehydrate the niobic acid. After heating to reflux, evaporate to nearly dryness, and after cooling slightly, dissolve the soluble salts in the sample with 200ml of hot ...

Embodiment 3

[0097] Dilute the obtained sample digestion solution 2* to 130ml. Follow the same procedure as above for sample processing to prepare sample blank test solution.

[0098] Add 1.5ml of 25% sodium tungstate solution dropwise to the sample digestion solution 2* and the sample blank solution respectively, and then add dropwise a 1% titanium trichloride solution to make the sample digestion solution 2* After the solid blue color and the sample blank solution respectively appear, stop the dropwise addition. The sodium tungstate solution is added dropwise in order to ensure that the titanium trichloride completely reduces the ferric iron to ferrous iron for subsequent reactions. Adding the titanium trichloride solution dropwise is to completely reduce the ferric iron in the sample digestion solution 2* to ferrous iron.

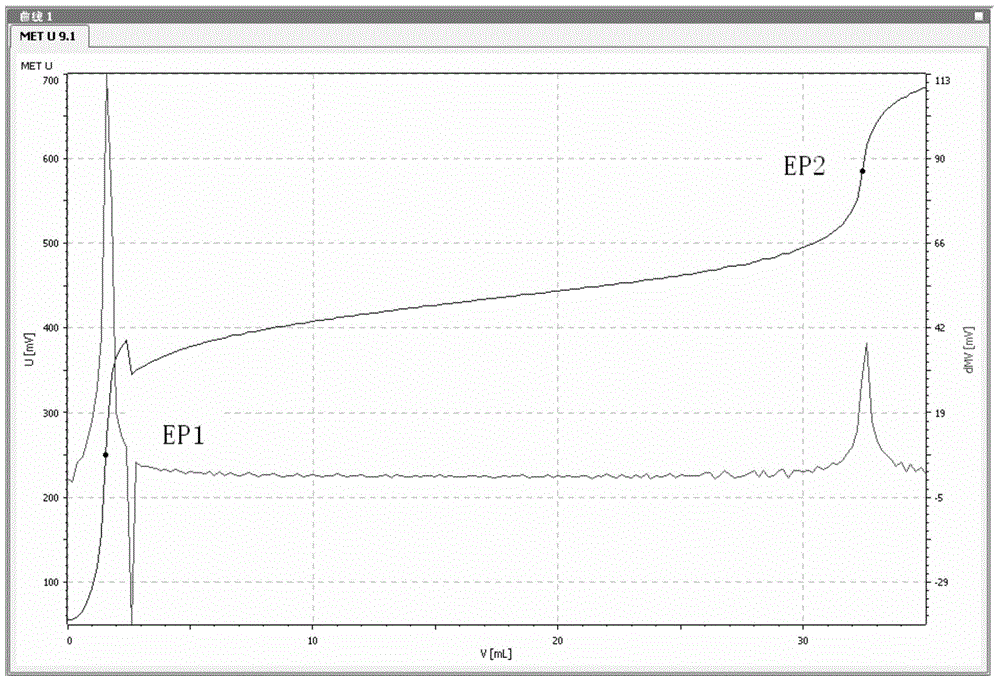

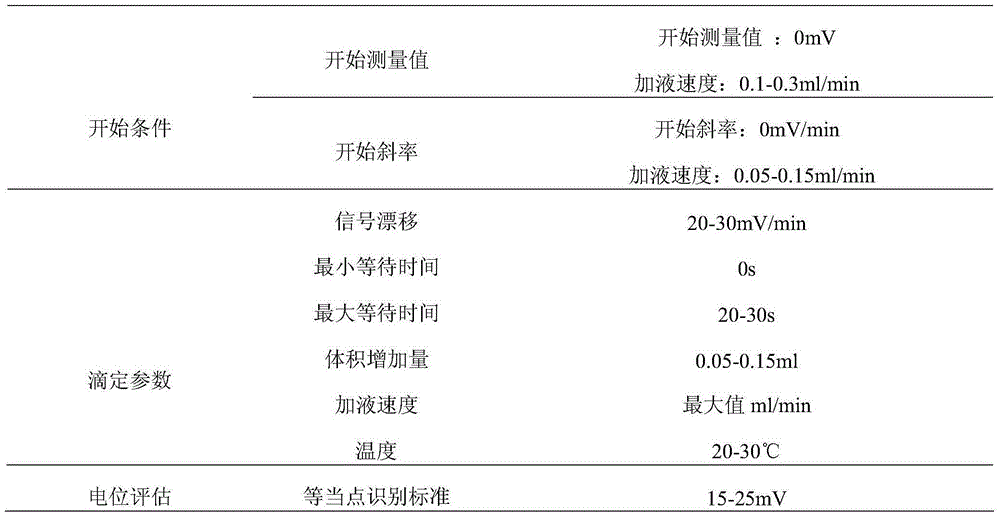

[0099] Then use an automatic potentiometric titrator to titrate the sample digestion solution 2* and the sample blank solution respectively with a potassium dichro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| percent by volume | aaaaa | aaaaa |

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com