Preparation method of lycopene microcapsules

A lycopene and microcapsule technology, applied in the fields of medicine and food, can solve problems such as limited application, and achieve the effects of reducing the content, broadening the scope of application, and inhibiting the characteristics of allergic reactions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

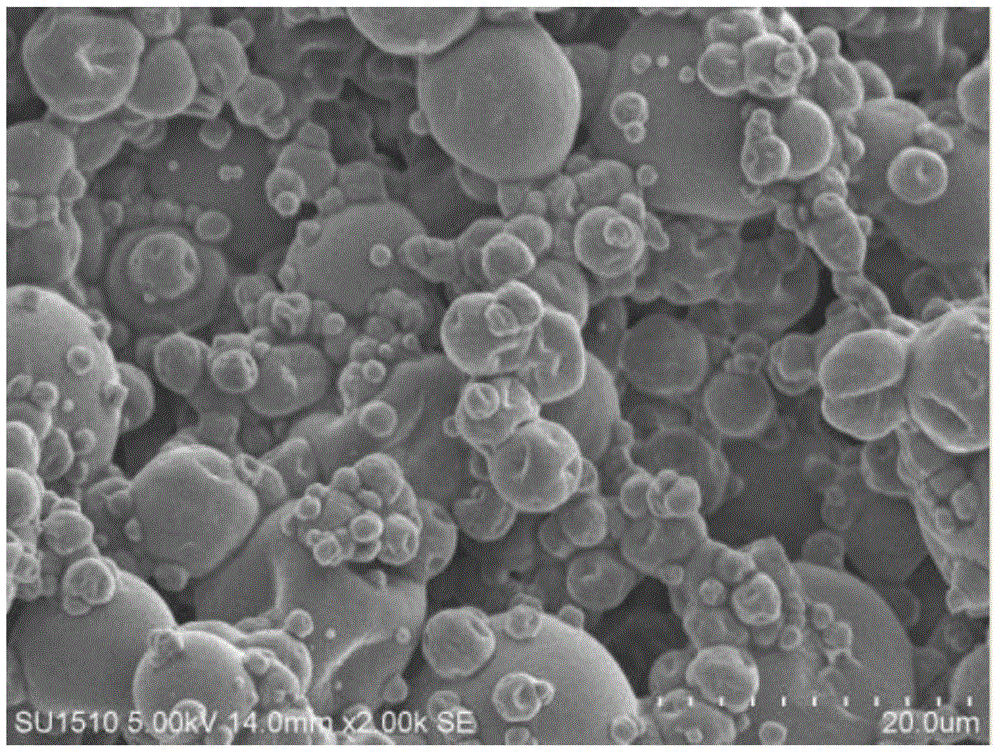

Image

Examples

preparation example Construction

[0025] The preparation method of the oil phase: 5 g of lycopene was dissolved in 50 mL of ethyl acetate, stirred and dissolved at 60° C. to obtain the oil phase.

[0026] Preparation of microcapsules: Take 10mL of uniformly mixed oil phase and slowly add it to the water phase of the wall material, and fully stir it. Considering the heat sensitivity of lycopene, evaporate the excess lycopene in the mixture at low temperature by rotary evaporation. organic solvent, so as to obtain the emulsion with solid content in accordance with the design of this experiment, and then homogenize it through a tissue grinder (15000r / min, 3min).

[0027] Lycopene emulsion was prepared by controlling different homogeneous pressures. Homogeneous pressure helps the core material and wall material to be fully mixed to improve the embedding effect, but too high homogeneous pressure will also make the lycopene emulsion droplet smaller and the surface free energy of the system increase, resulting in an ...

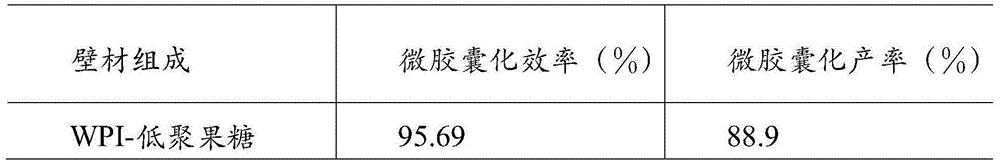

Embodiment 1

[0040] Prepare the optimized wall material formula into a solution: add 6g of whey protein isolate and 12g of fructooligosaccharide in a ratio of 1:2, control the reaction system pH=9, react at 90°C for 2 hours, and mix 10mL evenly Slowly add the core material solution into the wall material solution, and fully stir, and use the rotary evaporation method to evaporate the excess organic solvent in the mixed solution at a low temperature of 35-40°C, and homogenize for 3 minutes under the condition of 15000r / min . The microcapsule emulsion homogenized by the tissue masher was homogenized twice under the homogenization pressure of 40MPa.

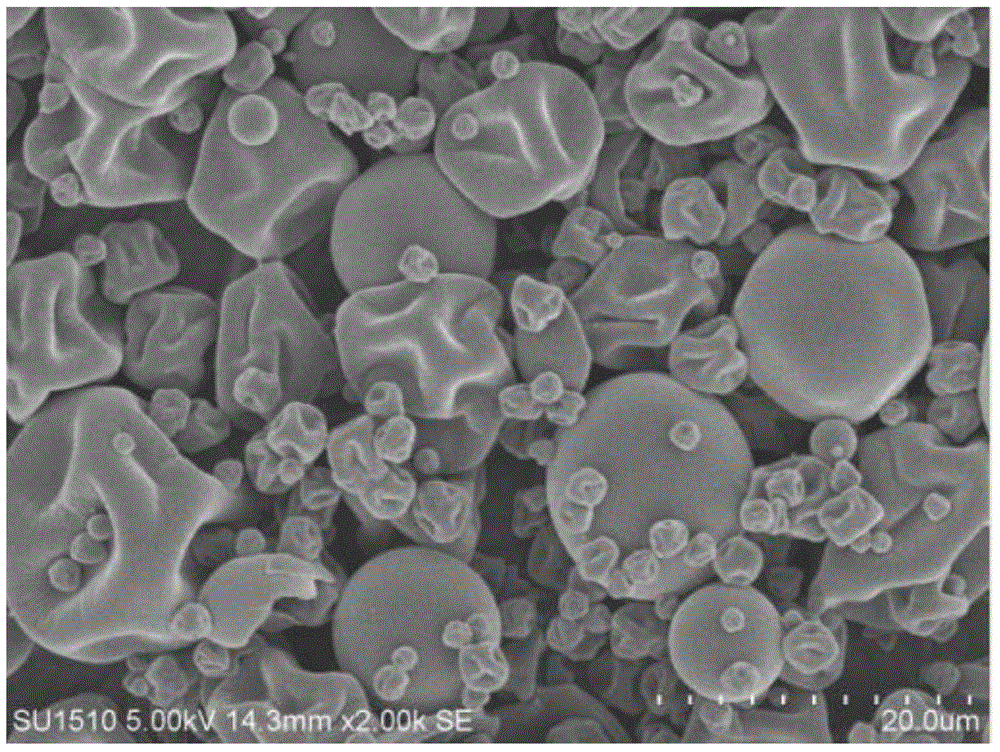

Embodiment 2

[0042] Prepare the optimized wall material formula into a solution: add 6g of whey protein isolate and 12g of xylooligosaccharide in a ratio of 1:2, control the pH of the reaction system to 10, react at 90°C for 3h, and mix 10mL The uniform core material solution is slowly added to the wall material solution, and fully stirred, and the excess organic solvent in the mixed solution is evaporated at a low temperature of 35-40°C by rotary evaporation, and homogenized under the condition of 15000r / min. 3min. The microcapsule emulsion homogenized by the tissue masher was homogenized twice under the homogenization pressure of 40MPa.

[0043] The detection result of the lycopene microcapsule embedding effect of the present embodiment:

[0044]

[0045]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com