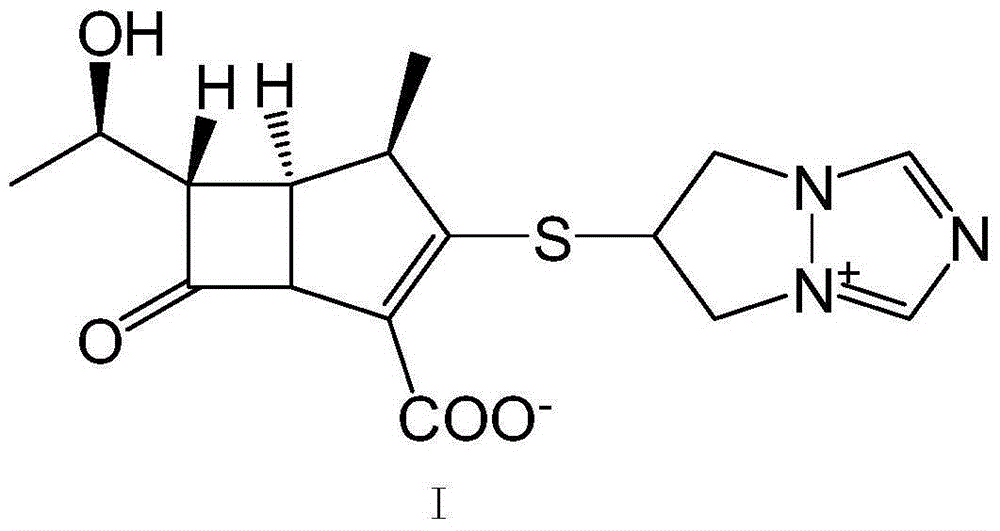

Refining method of biapenem crude product

A refined method, the technology of biapenem, which is applied in the field of medicine, can solve the problems of difficult expansion and shortage, and achieve the effects of reduced usage, simple method, high yield and purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

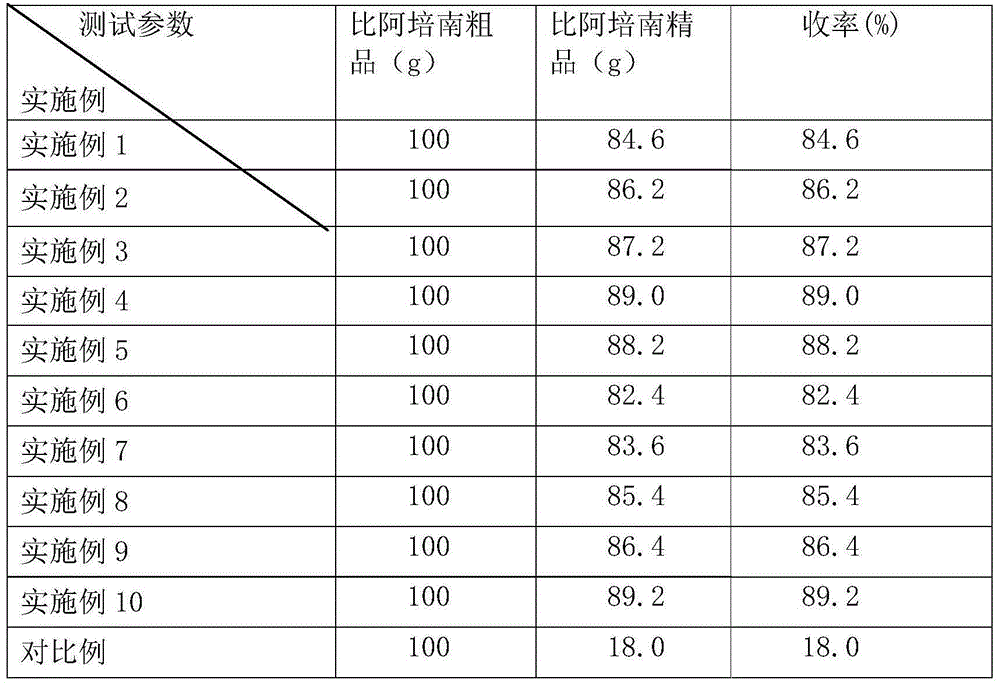

Examples

Embodiment 1

[0039] Dissolve 100g of crude biapenem in 500mL of 80% formic acid purified aqueous solution at room temperature, add 3.0g of activated carbon and stir for 15min to decolorize, filter, and filter the filtrate through a 0.22μm filter membrane, transfer the filtrate to a 2000mL reaction flask, add 1000mL of 95% ethanol dropwise . After the dropwise addition, the reaction was stirred for 2h and filtered. After drying, 84.6g of biapenem fine product was obtained. Yield 84.6%.

Embodiment 2

[0041] Dissolve 100g of crude biapenem in 500mL of 60% formic acid purified aqueous solution at room temperature, add 3.0g of activated carbon and stir for 15min to decolorize, filter, and filter the filtrate through a 0.22μm filter membrane, transfer the filtrate to a 2000mL reaction flask, add dropwise 1000mL of 95% ethanol . After the dropwise addition, the reaction was stirred for 2h and filtered. After drying, 86.2g of biapenem fine product was obtained. Yield 86.2%.

Embodiment 3

[0043] Dissolve 100g of crude biapenem in 500mL of 50% formic acid purified aqueous solution at room temperature, add 3.0g of activated carbon and stir for 15min to decolorize, filter, and filter the filtrate through a 0.22μm filter membrane, transfer the filtrate to a 2000mL reaction flask, add 1000mL of 95% ethanol dropwise . After the dropwise addition, the reaction was stirred for 2h and filtered. After drying, 87.2g of biapenem fine product was obtained. Yield 87.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com