Preparation method for floatable nano mesoporous zero-valent iron carbon material

A nano-mesoporous, zero-valent iron technology, applied in chemical instruments and methods, adsorption water/sewage treatment, water pollutants, etc., can solve the problems of high density, hardening, low iron-carbon reactivity, etc., and achieve high reactivity. , the energy consumption is large, and the effect of improving the pollution removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

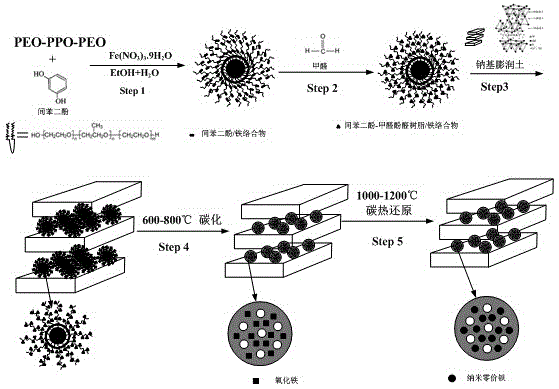

[0024] The preparation method of the floatable nano mesoporous zero-valent iron-carbon material is to synthesize the floatable nano-mesoporous zero-valent iron-carbon material in one step through multi-component cooperative self-assembly, extraction, heating carbonization and carbothermal reduction, and the specific steps include as follows

[0025] (1) First, add 1.9g of F127 to 40ml of ethanol-water solution with a volume ratio of 1:2 and stir until fully dissolved, then add 1.0g of resorcinol, 1.2g of Fe(NO 3 ) 3 9H 2 O stirred for 1h, finally added 1.62g formaldehyde (37wt%) solution and stirred fully at room temperature for 6h to prepare the phenolic resin / iron complex of resorcinol-formaldehyde, wherein resorcinol, Fe(NO 3 ) 3 9H 2 The molar mass ratio of O, formaldehyde and F127 is 1:0.3:1.5:0.015;

[0026](2) Add 5.40 g of sodium bentonite (360 g / mol) to ethanol-water solution with a volume ratio of 1:2 to form a 10% sodium bentonite ethanol-water suspension by ma...

Embodiment 2

[0031] The preparation method of the floatable nano mesoporous zero-valent iron-carbon material is to synthesize the floatable nano-mesoporous zero-valent iron-carbon material in one step through multi-component cooperative self-assembly, extraction, heating carbonization and carbothermal reduction, and the specific steps include as follows

[0032] (1) First, add 0.87g of P123 to 40ml of ethanol-water solution with a volume ratio of 1:2 and stir until fully dissolved, then add 1.0g of resorcinol, 1.2g of Fe(NO 3 ) 3 9H 2 O stirred for 1h, finally added 1.62g formaldehyde (37wt%) solution and stirred fully at room temperature for 6h to prepare the aldehyde resin / iron complex of resorcinol-formaldehyde, wherein resorcinol, Fe(NO 3 ) 3 9H 2 The molar mass ratio of O, formaldehyde and P123 is 1:0.3:1.5:0.015;

[0033] (2) Add 5.40 g of sodium bentonite to ethanol-water solution with a volume ratio of 1:2 to form a 10% sodium bentonite ethanol-water suspension by mass, and ad...

Embodiment 3

[0038] The preparation method of the floatable nano mesoporous zero-valent iron-carbon material is to synthesize the floatable nano-mesoporous zero-valent iron-carbon material in one step through multi-component cooperative self-assembly, extraction, heating carbonization and carbothermal reduction, and the specific steps include as follows

[0039] (1) First, add 1.9g of F127 to 40ml of ethanol-water solution with a volume ratio of 1:2 and stir until fully dissolved, then add 1.0g of resorcinol, 2.0g of Fe(NO 3 ) 3 9H 2 O stirred for 2h, finally added 1.22g formaldehyde (37wt%) solution and stirred fully at room temperature for 6h to prepare the aldehyde resin / iron complex of resorcinol-formaldehyde, wherein resorcinol, Fe(NO 3 ) 3 9H 2 The molar mass ratio of O, formaldehyde and F127 is 1:0.5:1:0.015;

[0040] (2) Add 5.40 g of sodium bentonite to ethanol-water solution with a volume ratio of 1:2 to form a 10% sodium bentonite ethanol-water suspension by mass, and add r...

PUM

| Property | Measurement | Unit |

|---|---|---|

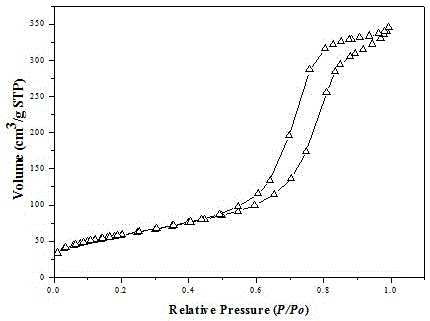

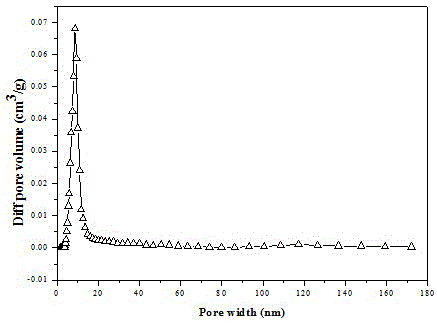

| Specific surface area | aaaaa | aaaaa |

| Total pore volume | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com